Delivering Safe and Cost Effective Packaging Solutions

The highly globalized vehicle industry takes advantage of advanced manufacturing, development, and logistics flows, but its complexity requires a variety of packaging materials. Without the right packaging solutions, vehicle parts could be damaged during shipment, and transport costs could get out of control. At Nefab, we help businesses to create customized vehicle part packaging and shipping solutions in order to protect products while minimizing costs.

Types of Automotive industry Packaging

When it comes to shipping automotive parts, there are two main types of packaging used by manufacturers: expendable and returnable.

Expendable Packaging

Expendable packaging is disposable, and it is made out of materials like paper, plywood, wood, or corrugated cardboard. These types of products are generally viewed as single-use packaging solutions that will be recycled or thrown out after the vehicle part reaches its final destination. A regular disposal process for materials needs to be incorporated into the lifecycle of the manufacturing and packaging process.

Returnable Packaging

Returnable packaging solutions have been designed for reuse in manufacturing and distribution systems. With this type of packaging, the need to purchase disposable packaging – which will need to be recycled or routed to a landfill – is reduced or eliminated entirely.

Returnable packaging includes reusable racks, pallets, bulk containers, dunnage, and hand-held containers. Plywood containers, plastic containers, steel containers and pallet collars are also popular, and use of these packaging solutions come with a wealth of benefits:

- Reduction of packaging waste

- Improved control of inventory due to box tracking

- Protection of valuable vehicle parts due to packaging rigidity

- Reduction of the carbon footprint

- Protection from contamination and moisture in sealed boxes

- Parts protection and ergonomics

A returnable packaging system is best suited for closed logistic systems with fixed arrival and distribution points. The general rule is the longer the logistics leg, the less practical it becomes to return returnable containers. Most returnable packaging within the automotive industry circulates around short loops, and by replacing a one-way packaging solution with a returnable alternative, both expendable and returnable waste can be minimized.

Nefab Offers Optimized Packaging Solutions for the Automotive industry

In addition to our returnable and expendable packaging solutions, we also have extensive experience in “knock-down units.”

At Nefab, we offer customized packaging solutions for the vehicle industry. Our mission is to help customers to fulfill their commitments in a convenient, safe, and cost-effective manner. We do this by performing a comprehensive evaluation of all product shipments in order to implement a concept to reduce total transport costs.

Our customers are found at every stage of the automotive industry. From component and system manufacturers to major vehicle manufacturers, we work to create packaging solutions developed specifically for our customers' supply chains. We create packaging solutions for both the inbound and outbound flows and for after sales.

In addition to our returnable and expendable packaging solutions, we also have extensive experience in "knock-down units." This means that all full sets of automotive components are transported in parts for assembly at a factory in another part of the world. We offer worldwide service and coordination at a local level, which has become a basic requirement of the vehicle industry.

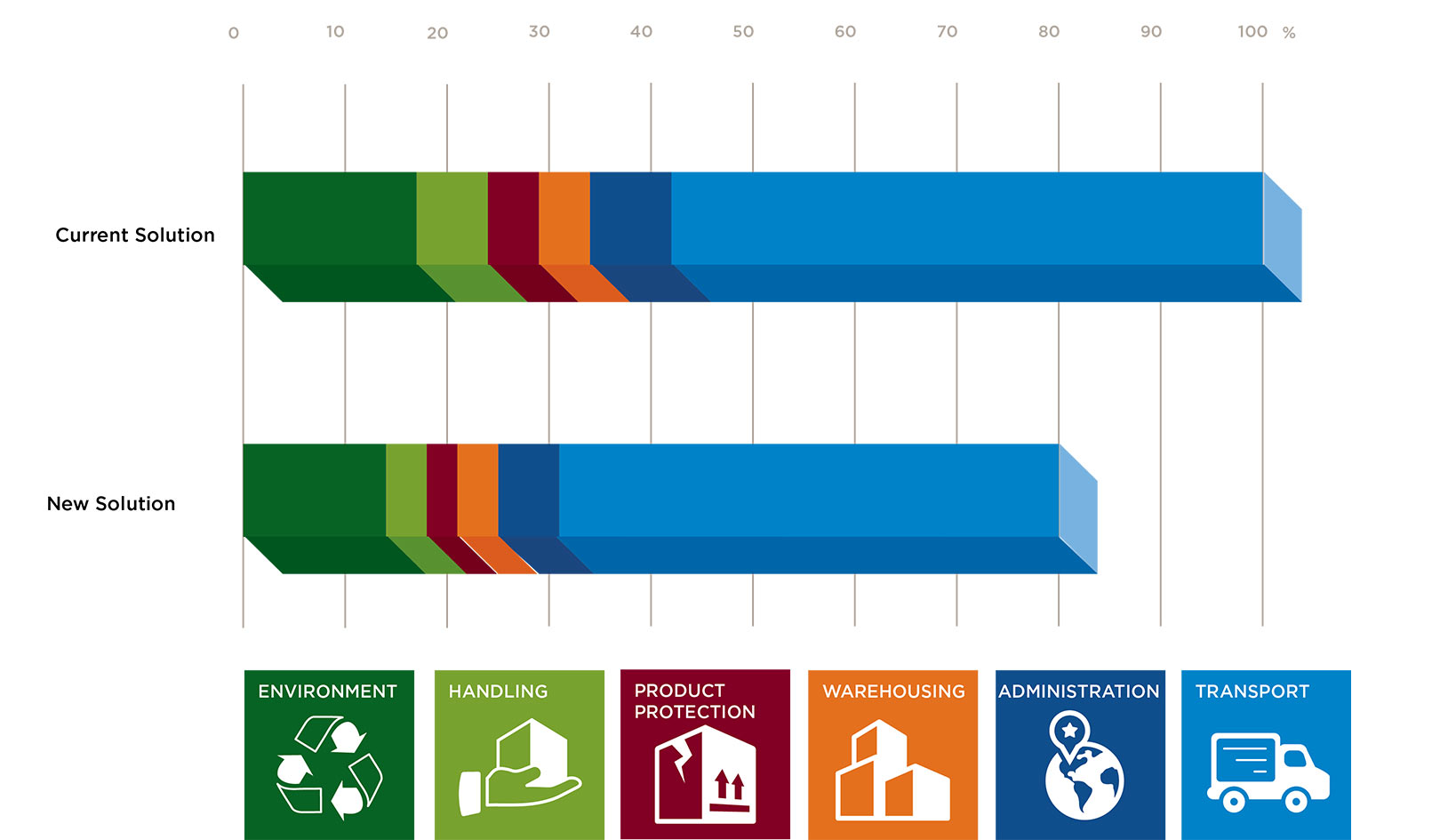

Our Total Cost Approach

At Nefab, we believe that a packaging solution should save more money that in costs. Packaging represents a relatively small share of a company's total costs, but the choice of packaging will have a major impact on other cost items. That's why we offer a total cost approach to help our clients create the best packaging solutions:

- Transportation. We will optimize your packaging weight and size in order to increase transport efficiency.

- Environment. We work hard to improve or eliminate waste handling while increasing reusability.

- Handling. Our packaging solutions reduce packing time and improve ergonomics.

- Product protection. We offer optimized packaging solutions in terms of production protection vs. product damage costs.

- Warehouse. We create solutions that will reduce your storage space needs and minimize the capital costs of packaging stock and finished goods.

- Administration. We will work to reduce costs for order administration by delivering complete packaging sets.

At Nefab, we offer a total cost approach that ensures packaging is optimized, reducing the total cost in your supply chain. Our global supply and service capabilities will ensure that we are always there to provide both local support and global coordination. Contact us today to learn more about these services.