Choose the Right Packaging Material

When the time comes to choose a packaging solution for your products, you’ll want to select a material that travels well, looks great, offers the right protection, and fits within your budget. However, it is often difficult to determine exactly which material checks all of those boxes. With so many different options to choose from ranging from thermoplastics to wooden crates, it is important to know more about each of your choices, as well as some important factors to consider when you make your selection.

Important Considerations When Choosing Your Packaging Materials

Are you in need of packaging for your products? If so, it is crucial that you choose the right materials so that your products arrive at their final destination safely, without damage, and at the lowest possible cost. Keep these considerations in mind when reviewing your options:

Mode of transportation. When selecting a packaging material, you’ll want to consider how your products will be transported, as the mode of transport can make a big difference on how to secure your packages. For example, packages being shipped by air will need to be prepared for atmospheric changes and turbulence, while ground transport packages need to be ready for potentially rough roads and manual handling.

Moisture.

Exposure to moisture – whether this is due to ocean shipping, coming into contact with rain during transportation, or simply being stored in a humid warehouse – can make a major impact on the type of packaging that you choose. There are certain packaging options that won’t stand up well to moisture, such as corrugated cardboard. Paper is a living material that will absorb water, and dampness will weaken its ability to protect your products.

Product characteristics.

Weight, shape of the package, and size of the product are all important considerations when choosing the right packaging material. The more information that is available about the actual product, the easier it will be to determine the right material.

Size. The right size of shipping container is also crucial. A box or crate that is too large will be more expensive than necessary, and the extra room inside of the container can lead to shifting of merchandise and the potential for damage.

Temperature. Your packaging solutions need to safeguard your products while keeping them at an optimal temperature. This is especially true if you are shipping perishable items, so keep the potential variations that your products will experience in mind as you research possible packaging options.

Budget.

Like any purchase for your business, you’ll want to consider your budget when choosing your packaging materials. However, don’t make the mistake of only keeping upfront costs in mind when weighing whether a packaging solution is the right option. In some cases, choosing the cheapest packaging can cost you more money in the long run, especially if it ends up being an ineffective solution that leads to damaged products and reduced sales.

Product value.

Valuable products will likely need more secure materials than other items.

Strength/fragility. Fragile products will need more protection than strong and durable items. You’ll also need to take transportation and handling into consideration when shipping fragile products to ensure that your items aren’t damaged during transport.

Audience. It is also important to know your audience when choosing a packaging material. If your business prides itself on being environmentally-conscious, selecting a packaging material that is recyclable may be in your best interest in order to best convey that message.

Explore Your Packaging Options

"Corrugated packaging is arguably the most popular packaging material in the industry"

You have several options available for packaging your products. By better understanding a little about each of them – including the pros and cons – you can make an informed decision about which materials will work best for your business.

Wooden boxes and crates are arguably one the most secure of the available packaging materials, but they are also the heaviest and least flexible option. Wood is often used for large products, heavy and difficult loads, and when long-term storing might be needed.

Corrugated packaging is arguably the most popular packaging material in the industry, mostly because of its low cost. Corrugated board also offers top-notch product protection, and the material is both lightweight and easily customizable. Unfortunately, it does not stand up well to rough handling or moisture, so these issues should be taken into consideration during the planning process.

Plywood crates generally offers superior protection when compared to corrugated materials. Plywood shipping solutions will allow a box to breathe, which can minimize the moisture exposure during transport. Plywood boxes are often lighter than the wooden crates and they are compliant for export shipping.

Steel-based packaging is a flexible packaging design solution, as it can be adapted to suit many different uses. It is frequently used as a returnable packaging option, the most popular of which is collapsible racks. Steel racks are strong, long-lasting, and can protect the products from impact during transport and rough handling, and foldable steel racks are also popular options. Unfortunately, steel is prone to corrosion, so when choosing it as your packaging material, you’ll want to consider the hazards it will be exposed to and how long it will be out in the elements.

Plastics is an extremely versatile material, so it should come as no surprise that it is very useful in both retail and transport packaging. Plastic solutions are appreciated due to their light weight and cleanliness. Plastic solutions are easy to clean and very sturdy in relation to their weight.

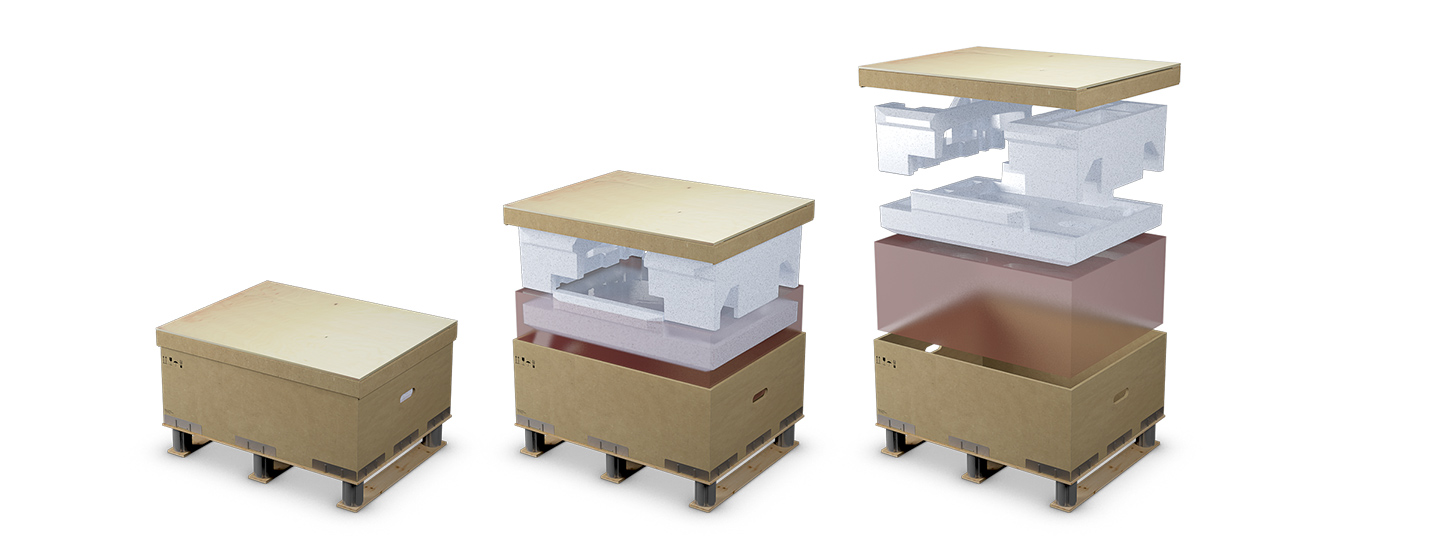

Don’t Forget About Inner Packaging

While the exterior packaging is crucial during the transport process, it is important that you don't forget the importance of inner packaging. There are several materials that you can use when packaging your products, so it is crucial that you weigh your options to ensure you are making the best decision.

Blocking & Filling Materials, during transport, your products will be at risk for damage due to drops, shock, vibration, and other hazard, so most industrial packaging solutions will use blocking and filling materials. These materials help to immobilize a product by providing cushioning that will protect the product and fill in any empty space. Examples of filling solutions are: Paper pad, Air pad, Foam-in-place, Loose fill

Cushioning can help to cut back on damage due to vibrations and shock during the transportation process. Different foam materials are available for cushioning protection. Solutions are designed based on the product fragility, method of transportation and destination.

ESD packaging stands for Electro Static Discharge, and it works to prevent against damage to electronic equipment. Electronics are especially susceptible to operational disturbances during transport, and ESD protection can ensure that your product arrives at its final destination safely. ESD packaging is also completely customizable and is available in a wide range of material options.

Corrosion Protection is important if your packaging will be exposed to water or moisture during the transport process. Inner corrosion protection can ensure that your items aren't damaged by corrosion during transport or storing.

Inner Fittings can be made from a variety of materials, including foam, steel, rubber, plastic, or plywood. Inner fittings offer product separation and can reduce vibrations, and they also simplify the packing and unpacking process.

Nefab is Here to Help

Choosing the right packaging material for transport is a major decision that shouldn’t be taken lightly, as the wrong materials could put both the safety of your products and your reputation in jeopardy. The right packaging will minimize the risk of damage, ensuring that your product arrives at its final destination safely and within a professional-appearing package. This will show your customers that you take pride in offering quality products and service, even throughout the transportation process.

At Nefab, we work hard to help our customers choose the packaging solutions that work best for their products and business. We know that it can be challenging to find packaging materials that are attractive, safe, and affordable, and we are committed to helping our customers select the best solutions. Our goal is to always ensure that products are arriving at their final destination safely in the most cost-effective packaging possible. Click on the links to find out more about our different export products, both expendable packaging and returnable packaging alternatives.