- News & Insights

- 2022

- 3 benefits of thermoformed plastics for sustainable supply chains

- Sustainability

- Innovation

NEWS & INSIGHTS

3 benefits of thermoformed plastics

Solutions for sustainable supply chains

Thermoplastics are among the fastest-growing plastic materials in demand

According to Statista, the global production of thermoplastics will amount to 445.25 million metric tons in 2025, with a 30% increase to follow in 2050.

From electric wires and cables, automotive seat covers to Lithium-Ion Battery packaging, the number of applications for thermoplastics is limitless. Besides being highly customizable and protective, thermoformed plastics can be applied to circular flows and reduce costs in handling and logistics due to high nestability.

Learn more about the main benefits of thermoformed plastics and how they contribute to building sustainable supply chains.

1. Limitless reusability

Thermoformed solutions are produced from polymer resins that soften when heated and harden when cooled during thermoforming or vacuum forming technology. This means that they can be easily molded, customized, and engineered not once, but multiple times. Additionally, they do not experience any changes to their chemical properties when processed, which makes them one of the most sustainable plastic packaging products available (Recycled Packaging). This enhanced reusability also offers limitless branding opportunities to customize the packaging at the point of sale and increase product visibility.

Thermoformed plastics can be collected, cleaned, grinded, and reused multiple times.

Thermoformed plastics can be collected, cleaned, grinded, and reused multiple times.

2. Enhanced protection

Thermoformed plastics have a light structure that makes them an ideal material for packaging, storage, and transportation. They can be custom-made to meet various shock absorption requirements for specific products, like Lithium-ion Batteries, Telecom/Datacom products, Automotive parts, and other dangerous and fragile goods. Moreover, their ability to be molded into various shapes allows numerous sealing options that can extend product’s shelf life and enhance protection against contamination. This feature also makes it easier to open and reclose the packaging.

Thermoformed Solutions applied to Datacom applications

Thermoformed Solutions applied to Datacom applications

Thermoformed Solutions applied to Lithium-ion Battery applications

Thermoformed Solutions applied to Lithium-ion Battery applications

3. Cost-effective sustainability

Compared to standard injection molding alternatives, thermoplastic packaging is typically more cost-effective. And thanks to their durability, they are a perfect fit for return and circular flows, contributing to sustainable supply chains (Online Sciences).

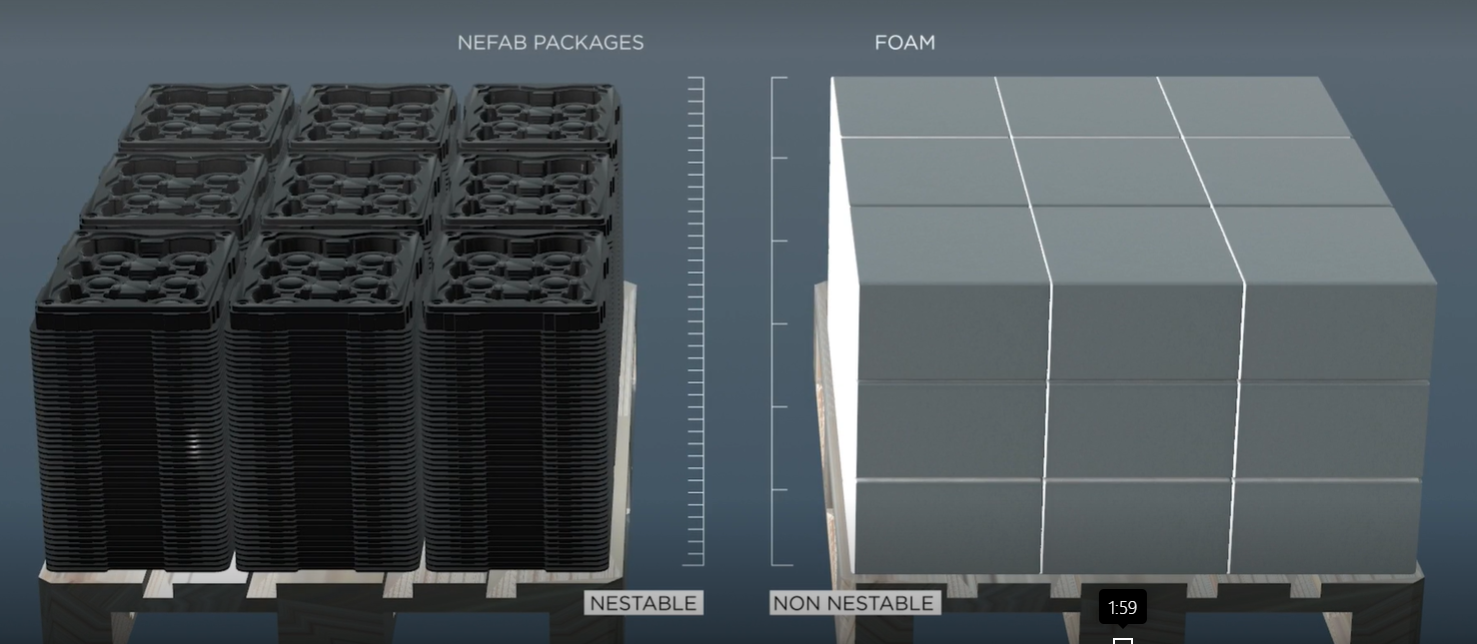

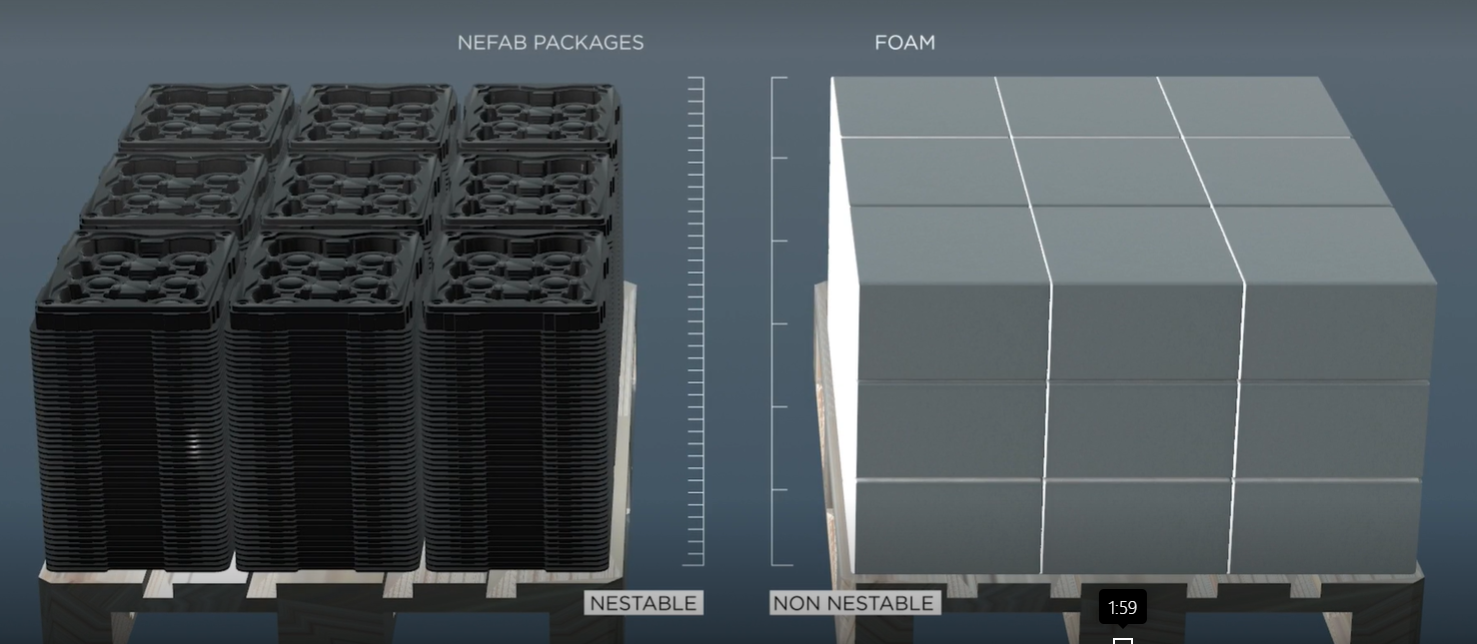

When compared to foam, thermoformed plastics perform better in terms of nestability, saving costs in handling and logistics in supply chains. Besides significant material and cost savings, thermoplastics also contribute to lower CO2 emissions when compared to foam.

At Nefab, we constantly strive to expand our sustainable portfolio. Between 2020 and 2021, we made important acquisitions, including Szkaliczki and Partners Plastic Processing Ltd (Szkaliczki), which secures Nefab’s leading position in technology and engineering capabilities and production of thermoformed trays, and, more recently, Reflex Packaging (Reflex) which secures Nefab’s global leadership in production of thermoformed cushioning solutions.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our circular plastics solutions.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials