Customizable tobacco packaging products

To meet the expanding needs of multinational corporations, the Nefab concept embraces the entire logistics chain, from qualified packaging consultancy to final delivery of complete packaging solutions for transport and materials handling.

Model NCC, Rigid, Non-Foldable

Model NCC is a non-foldable 1.0-2.0 m³ Cutfiller Bin with extraordinary physical qualities. The bins within the NCC portfolio are metal protected on all exposed to-wear parts and manufactured to withstand the roughest handling for years. The NCC-model is mounted in either a electro galvanized or stainless steel bottom tub pressed into one piece and welded only along the vertical corners. This provides the strongest construction possible and maximum protection against conveyor belt wear and rough clamp truck or forklift handling. Features like wheels, runners, pallet bases, identification data chips and numbers, barcodes and much more can be added to secure efficient handling.

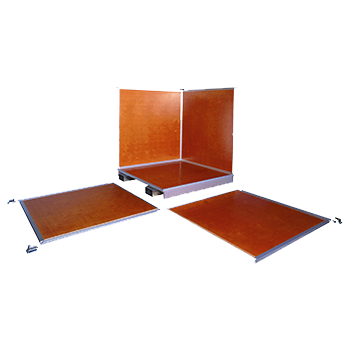

Model FCB - Foldable, Large Volume Bin

Our large volume bin - model FCB (Foldable Cutfiller Bin) - fulfills the demand for both large volume Cutfiller Bins and easy and flat packed shipping to any destination in the world. The FCB-model is available in nearly any size required. From 1 m3, or smaller, to large volume bins of 6.75 m3 corresponding to more than 1000 kilos of cutfiller. Special designed aluminum profiles provides easy on site assembling and extraordinary strength.

Largest standard size is 3000 x 1471 x 1471 mm (Approx. 120" x 59" x 61"). Larger non-standard sizes are also available upon request.

V-Model

Pre assembled Tobacco Packaging Containers. Nefab introduces a new version of the NCC-model. The new Nefab Cutfiller Bin has a slightly conical design, which makes the emptying process even more effective. This model is pre-assembled in factory and transported in parts to final destination.

- "The combination of the special film faced plywood and the conical design makes the release of tobacco very effective. Even if the tobacco has been pressed into the cutfiller bin it will fall out when tipping the bin, leaving no tobacco inside", says Per Bertilsson, Product Manager for Cutfiller Bins..

The new 2,0 m3 version of the NCC-model, conic by 1°, will save space and time in the handing system.

Customized Tobacco Packaging Solutions

The Nefab Cutfiller Bin can be customized satisfy any cigarette factory's specific requirements. The bins are made entirely according to the customer's wishes and can be manufactured in almost any shape and size to fit any existing, handling-, filler- or tipper system.

Customized solutions can be offered in small as well as in large quantities.

ABOUT

Nefab Cutfiller Bins are made with the strongest construction possible: stainless or electro-galvanized steel and high quality birch plywood. Because of a special film, which is hot pressed into the plywood, there is no condensation build-up and no static electricity, and therefore no dust accumulation. The non-contaminating film makes our bins resistant to the adherence of tobacco and stems.

GET IN CONTACT

Telephone: +46 (0)771 59 00 00

E-mail: kundservice@nefab.se