- News & Insights

- 2022

- Can returnable connected packaging future-proof supply chains in post-pandemic reality?

- Export Packaging

- Sustainability

- Innovation

- Corporate News

- People

NEWS & INSIGHTS

Can returnable connected packaging future-proof supply chains?

Can returnable connected packaging future-proof supply chains in a post-pandemic reality?

Today, in a post-pandemic world and in light of developing trends such as regionalization, every business needs to implement solutions that improve supply chain risk prediction and management, and that provide high-level strategic foresight. Returnable connected systems promise to address both challenges - here is how.

One of the key lessons learned from the recent pandemic crisis is that localizing or regionalizing one’s production will reduce costs or at the very least help companies prepare for future disruptions. This, in turn, will demand increased customization of supply chain solutions, which will need to be smarter, better connected, automated, and sustainable.

As a result of these trends, every business needs to implement solutions that improve both supply chain risk prediction and management as well as provide high-level strategic foresight. Returnable connected systems address both challenges and can provide with better control and visibility of the entire process. This blog covers the key benefits of this solution and how to use it to successfully future-proof supply chains during the post-pandemic evolution.

New times call for new solutions

Although returnable systems have been around for over 20 years, some industries have yet to fully embrace their benefits. Now, more than ever, connectivity and visibility have dominated the discussion around the management of supply chains. Simply put, the future of supply chains is dependent on modern technology. Returnable connected systems are offering just that by connecting the tags on each packaging or pallet with transportation management software. This expedites packaging delivery from pick-up points to final destinations, enables real-time monitoring of logistic chain conditions, and anticipates potential risks. Investing in returnable connected systems can help to simplify all stages of supply chain management while also providing transparency and insight to improve decision-making.

Automotive executives recently reported a rise in the use of returnable packaging, driven by increased standardization of load carriers and more modular packaging concepts. Traditionally, manufacturers used returnable equipment within regions. The post-pandemic market, however, has seen an increased number of inter-continental returnable systems showing they can be cost-effective even beyond the 700km radius. In some cases, companies are going a step further by investing in shared, rented pools, or some hybrid types of returnable and one-way packaging. Delegating the management of long return flows to a third party allows a significant reduction of the total cost of ownership by switching to a shared flow which, in turn, frees-up assets that can be allocated elsewhere. This shared solution allows streamlining of the volatile supply chain by providing packaging in times of supply surge and making sure there are no empty boxes around the warehouse in downtime time. According to Nefab’s analytic tools, by connecting returnable packaging systems with their IoT platform the customers were able to optimize the pools’ size by 20%, improve their cycle times by 60%, and reduce the number of lost units in the system by 80%.

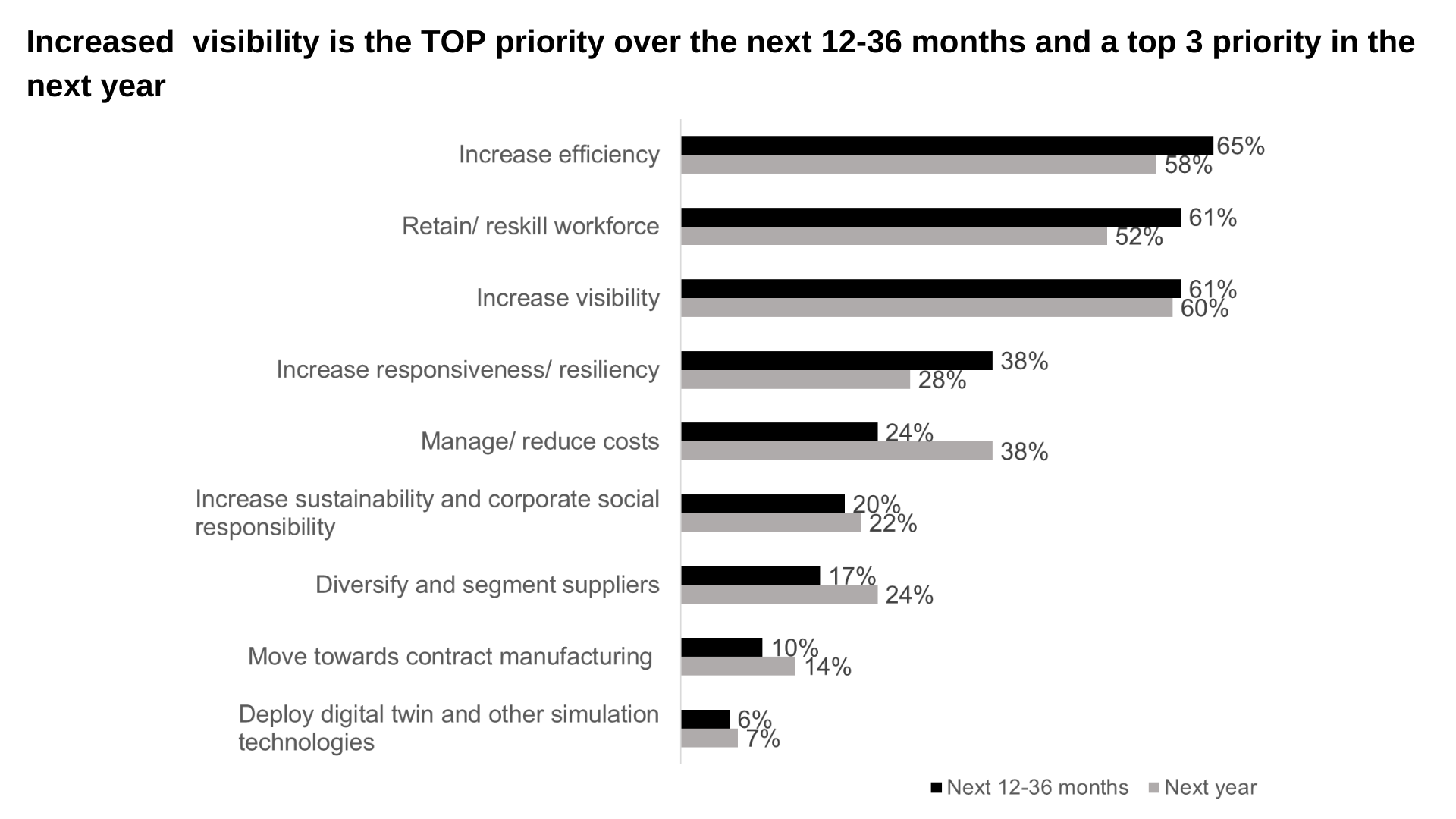

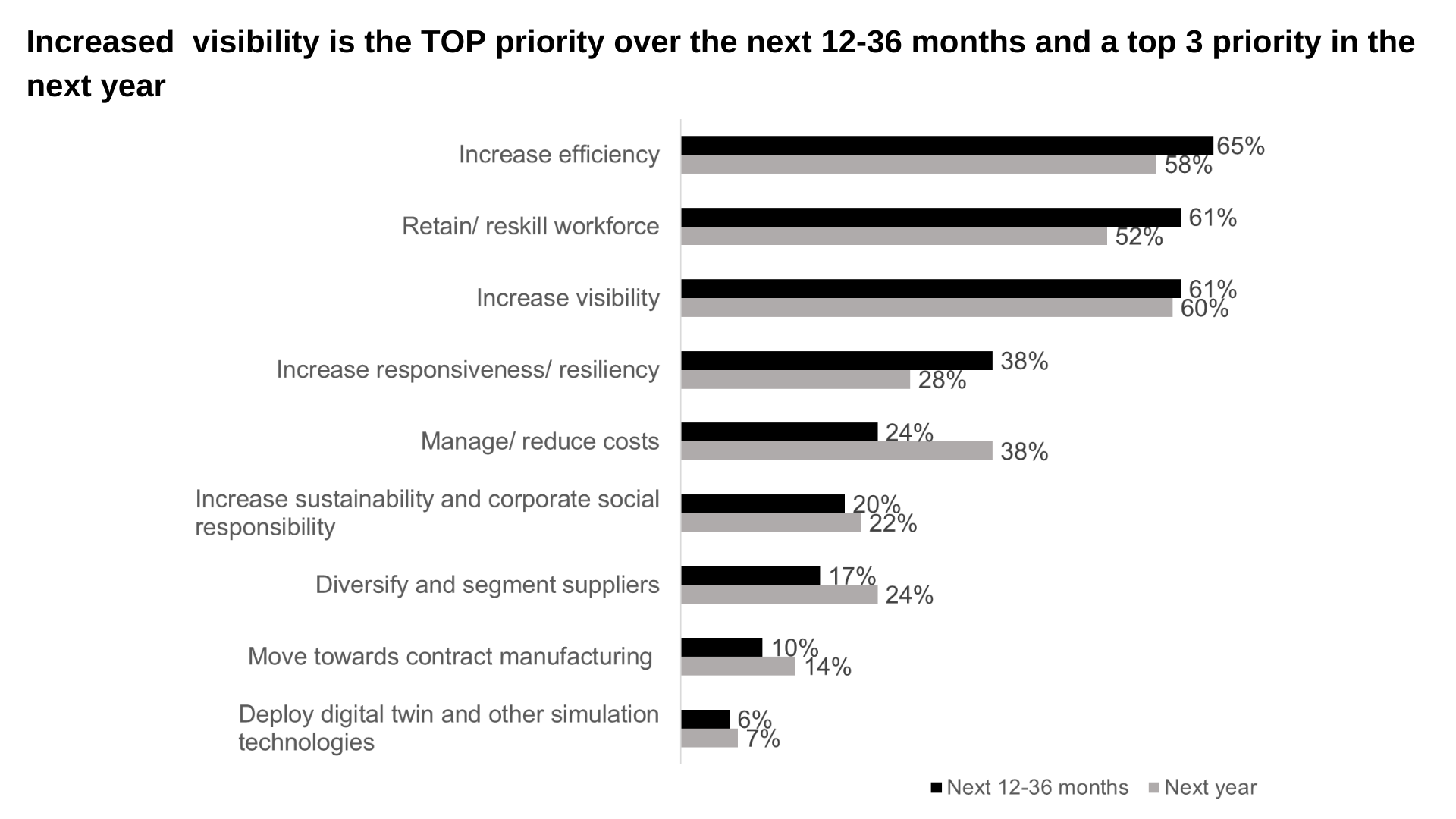

According to Ernst & Young’s survey from 2021, visibility and efficiency are the top concerns for companies in the next years.

Returnable system in practice

How does this returnable system work in practice? In short, it is a system of racks, pallets, or containers that can be used repeatedly for safe and efficient transportation of any type of product, from food and small electronics to lithium-ion batteries for electric cars. These solutions are available in a variety of materials ranging from steel and plastic to plywood, shapes and sizes, and a collapsible design that allows for space savings in transit and storage. Another benefit is that returnable systems are also custom designed, which means they help automate handling, unloading, and packing, save labor time and improve workplace safety.

As a result, one not only saves the materials used in packaging development and reduces the amount of waste generated, but also improves waste management. By simply replacing one-way packaging with a returnable solution, businesses can significantly reduce the costs of shipping, improve product protection, increase workers’ safety, reduce their environmental footprint, and boost brand reputation.

From steel boxes for maximum product protection to plywood packaging for bulky and heavy goods and plastic pallets for extended durability, returnable systems offer customized benefits for any product.

Optimize returns in a smart way

Returnable packaging solutions can be used for every step of the supply chain – including shipping products from the manufacturing site to another supplier, directly to the end destination, and shipping damaged returns. Once arrived at the destination, returnable boxes are collected and sent back to the distribution point, where they are cleaned, fixed if necessary, and made ready to be reused. The key to a successful implementation of this system, however, is a limited number of distribution points. This allows to keep track of packaging and reduce potential losses. Additionally, it also helps in optimizing the number of cycles in the flow and the amount of packaging required per shipment, thereby increasing the return on investment. The rule of thumb is to complete at least four cycles per year for the returnable system to fully pay off.

It's crucial to note that some suppliers offer return flows with an added value, from designing and manufacturing the pickup solutions (both packaging and the fleet), to maintaining, repairing, and recycling the preferred solution at the very end. This closed-loop system means that the solution can be reused, repaired, and remanufactured at the end of its life cycle.

Smart solutions for a sustainable future

To summarize, returnable packaging systems are a cost-effective and environmentally friendly alternative for customers with an extensive flow of goods and a limited number of distribution points. The investment pays off quickly if one uses them at least for four cycles per year. Keeping in mind the rising costs of transportation and the shift to regionalization of global supply chains, this solution has the potential to significantly cut down transportation costs.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our sustainable solutions.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials