- News & Insights

- 2022

- Three reasons why using track and trace technology will improve supply chain transparency and sustainability

News & Insights

Track and trace technology

Three reasons how it improves supply chain transparency and sustainability

It is estimated that up to 40% of returnable assets disappear each year globally because of breakage, misplacement, or theft.

According to McKinsey's featured insights, nearly 80% of logistics executives surveyed indicated they needed to improve and invest in digital planning to increase supply chain visibility. However, according to latest IBM study, the tricky part is that the end-to-end transparency must be based in a real-time, contextual understanding of all the right data in order to provide credible information and build smarter sustainable supply chains.

The big question is, how can companies obtain better visibility into the movement and condition of their shipments? The answer is straightforward: by using modern technology. The latest developments in the Internet of Things (IoT) and big data have an immense potential to enhance every supply chain process, from inventory forecasting to demand and sustainable supply chain management.

The transition to truly digital supply chains is more complex and volatile than ever, and to get there, companies must become more agile. This means that traditional solutions based on a single technology are no longer appropriate for the new reality. The blog post below outlines what to keep in mind to ensure that one is doing it right.

Smart data ensures better visibility

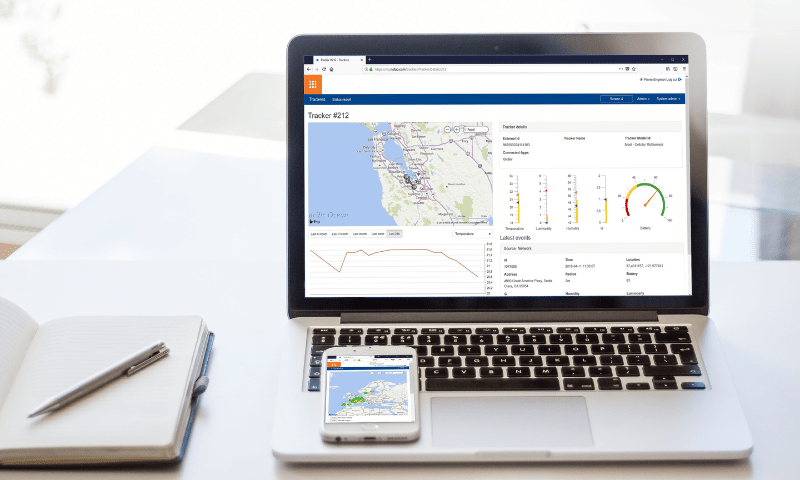

According to the trade media, the Internet-of-Things (IoT) is the most disruptive technology impacting supply chains today. In modern connected packaging solutions with advanced tracking capabilities, every asset is equipped with a sensor associated with a relevant data point. This data is then aggregated and reported in real-time. As packages are tracked in transit, it is simple to see where products are at any given time, when they will arrive, and in what sequence they are packed in a container.

However, smart packaging is capable of much more. Businesses can also monitor current stock levels and receive alerts when certain events occur, such as shock, tampering, or late deliveries. The data can also be used to assess routes, delivery performance, handling, utilization, and lead times. All of this would eventually improve processes, increase efficiency, and lower costs of connected flows. Lead time can be reduced by up to 65% in some cases.

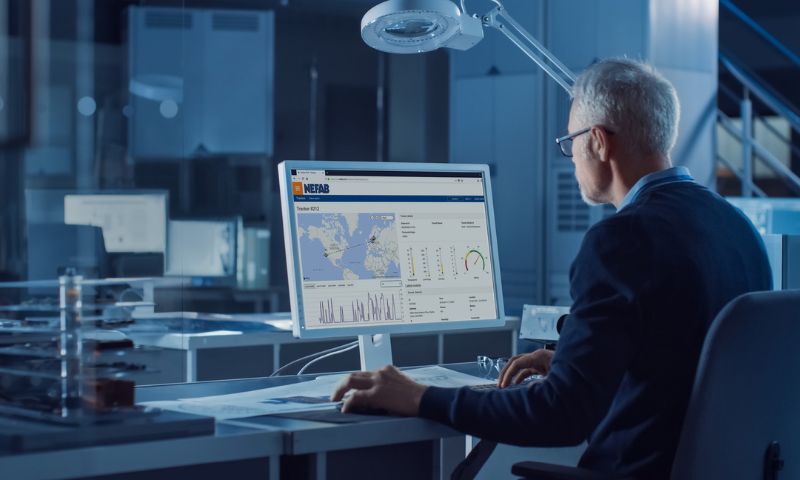

With multiple data sources, it can be challenging for companies to harmonize, interpret, and shared this data in an efficient way. There is no-one-size-fits-all solution either. Every company must ensure that the data they collect adds value and provides insight into their supply chain management. Therefore, it is critical to choose the right software that can quickly analyze the data to give valuable insights and create custom alerts and actionable reports. Centralized track and trace information hub should be tailored to the needs of every company and have user-friendly interface to avoid information paralysis.

Being tech-neutral is smart

The digitalization of the supply chain industry is well underway. Tracking technology is evolving at an unprecedented pace: new IoT networks are spreading fast, and cheaper devices emerge on the market daily. With no industry standards across the supply chain, each player is using their own preferred solution. Disparate technologies limit their capabilities. This siloed approach complicates data collection processes, reduces visibility, and consequently creates losses across the entire logistical flow.

To overcome those challenges, Nefab has created a technology-agnostic track and trace software for connected packaging allowing for full interoperability across different systems. Currently the network cooperates with over 70 different plug & play devices across different technologies and monitors over 80 million events daily from over 100 countries around the globe. This means that new, cheaper devices, regardless of their underlying technology (be that QR, RFID, connected gateways, GPS, Bluetooth etc.) can be added to the existing device fleet without the need to replace the current equipment and infrastructure. Nefab estimates that hybrid technology solutions help to save up to 95% in overall device costs.

The most advanced devices have up to 300 settings that can be configured to the desired preferences. For instance, the number of alerts can be decreased when the product is at the destination warehouse to conserve battery life and increased while the shipment is in transit, to increase product visibility and improve planning. Additionally, one can choose to switch on and off specific alerts to single out only the most important information, which can help to improve alert accuracy up to 99.9%. This unique technology-neural track and trace solution allows you to effectively profile and monitor the data for connected packages in global circulation.

By using a mix of technologies, Nefab’s track & trace platform provides, for example, real-time location in transit. This data can increase efficiencies as well as reduce costs of your connected flows, sometimes even up to 65% lead time.

Connected ecosystems pave way for smart sustainable supply chains

The future supply chains will have to be even more compatible and interconnected than today. According to the World Economic Forum research, sustainable technology solutions for supply chain management must be fully interoperate with other systems inside and outside of the company . It also stressed that companies with traceable value chain will outperform those without them. Gartner predicts that by 2026, over half of large organizations will compete as collaborative digital ecosystems rather than individual firms. This new, connected world will be driven by open source and technology neutral solutions that ensure mass personalization and smooth collaboration between all the ecosystem participants. Investing in a technology-agnostic platform can provide businesses with a competitive advantage now while also preparing them for future challenges.

Smart supply chain is also more sustainable. Technology improves and speeds up the decision-making process as well as helps to manage the inventory better which translates into greater economic sustainability. McKinsey estimates that supply chain is responsible for more than 80% of companies’ environmental impact. Digital tracing technology offers quicker route optimization and consequently decreases their ecological footprint. Finally, IoT solutions bring the accountability and automation to the logistical flows, which maximizes companies’ social impact.

At Nefab, by innovating together with our customers, we are finding new ways to save resources in supply chains.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our sustainable solutions driving supply chains forward.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials