- News & Insights

- 2023

- The power of circularity: reshaping supply chains to tackle plastic pollution

News & Insights

The power of circularity

Reshaping supply chains to tackle plastic pollution

The escalating levels of plastic pollution pose a significant worldwide threat to the environment, health, economy, and society.

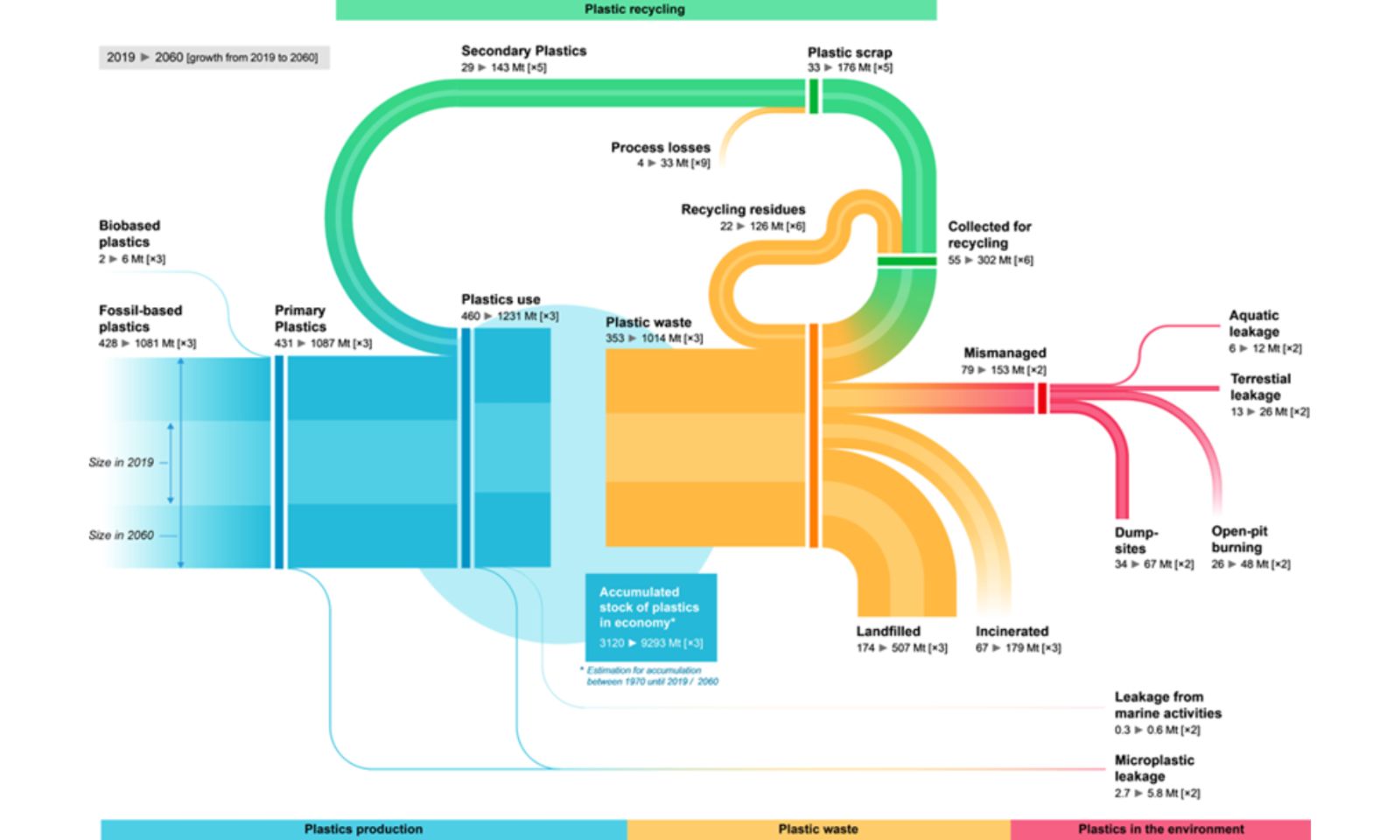

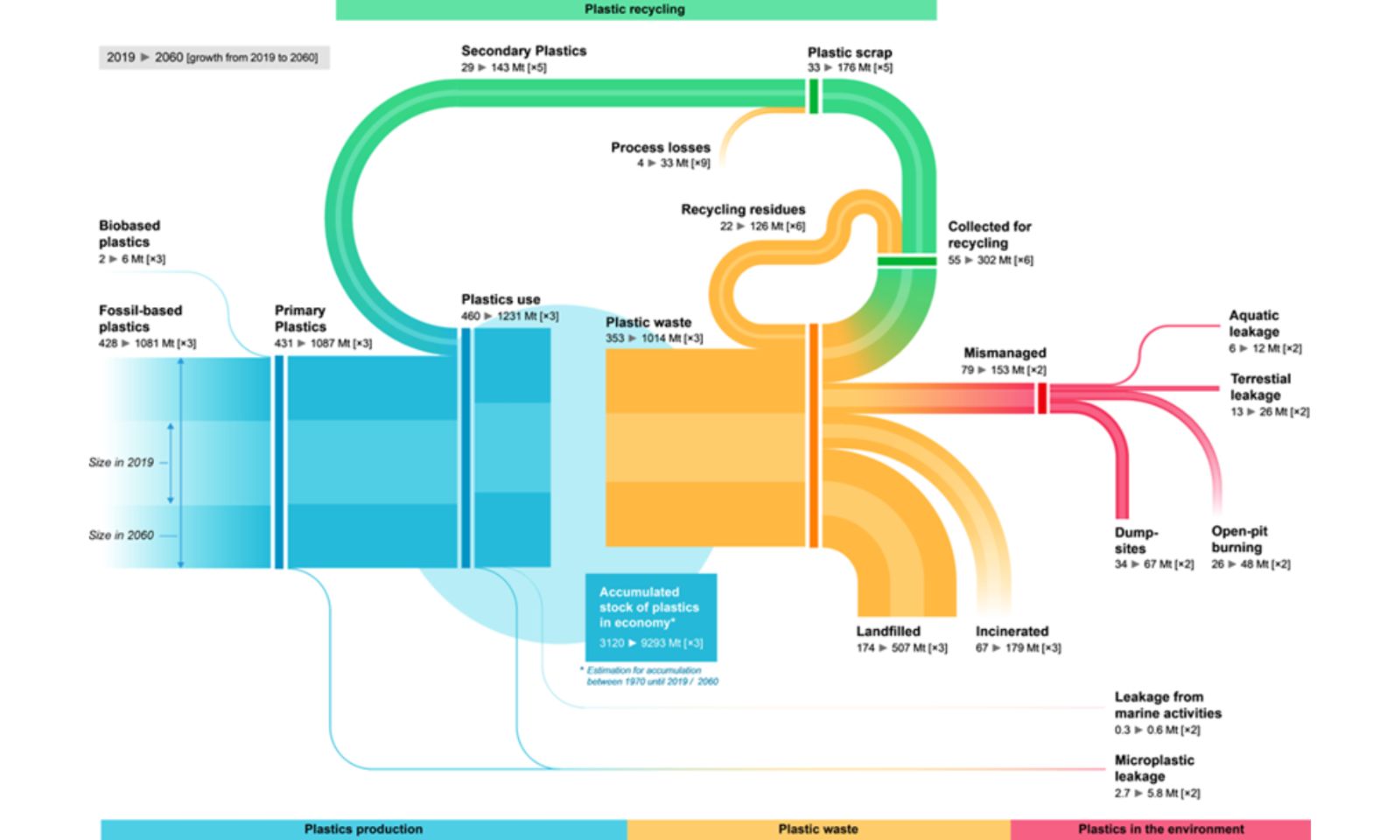

According to the Organization for Economic Cooperation and Development (OECD), under a business-as-usual scenario, the global production of plastic waste is projected to nearly triple by 2060. Approximately half of this waste is expected to end up in landfills, while less than one-fifth of it is anticipated to be recycled. The United Nations (UN) estimates that out of more than 400 million tons of plastic produced worldwide yearly, 33% is used just once1.

To combat the issue, the UN is working to develop a landmark treaty to end plastic pollution by 2040. The first draft of this legally binding international agreement would be presented by November, and the UN’s ambition is to agree on the final text in late 2024. UN Secretary-General Antonio Guterres said that governments, companies, and consumers alike must work ‘as one to break our addiction to plastics, champion zero waste, and build a truly circular economy2. ’ Follow along as we explore how can supply chain industry do its part.

Without the implementation of effective policies, OECD projects that the circularity of the plastic lifecycle will only reach 14% by the year 2060

Without the implementation of effective policies, OECD projects that the circularity of the plastic lifecycle will only reach 14% by the year 2060

Turning off the tap

Ahead of the May-June 2023 UN’s INC meeting in Paris, the UN environmental program (UNEP) published a report entitled ‘Turning off the Tap,’ which calls for transforming the market from linear to circular3. According to the document, addressing the root cause of plastic pollution requires comprehensive systems change. This approach involves a combination of strategies, including reducing the usage of problematic and unnecessary plastics, implementing three market shifts - Reuse, Recycle, and Reorient & Diversify - and undertaking actions to tackle the legacy of plastic pollution.

What do they stand for? Reuse refers to the transformation of the ‘throwaway economy’ to a ‘reuse society’ where reusing plastic products makes more economic sense. The report highlights the importance of accelerating the recycling market for plastic recycling by ensuring that it becomes a more profitable venture. Reorient and diversify, on the other hand, focus on shifting the market towards sustainable plastic alternatives, which will require a shift in consumer demand, regulatory frameworks, and costs. By implementing these measures, however, we can effectively tackle the plastic crisis and work towards a more sustainable future.

To cut plastic pollution by 80% globally by 2040, the UN suggests first eliminating problematic and unnecessary plastics to reduce the size of the problem. Subsequently, it calls for implementing three market shifts - reuse, recycle, and reorient & diversify3.

Reuse & recycling redesigned

According to the OECD, approximately 36% of all plastic produced is turned into packaging4. The good news is that there are many ways a company can reduce plastic waste by making more informed decisions in its supply chain planning. For instance, choosing packaging materials that can be reused or repurposed saves natural resources and keeps plastic in circulation, prolonging its value. Take-back systems are also gaining in popularity. Such closed-loop solutions are driven by the producers who collect the packaging at the end of its life and turn it into a usable form for creating something new. Pooling services are another excellent example of circular solutions. With no need to purchase their own, businesses can tap into the pool of shared packaging, adjusting the demand to their current needs. The pooling provider arranges pick-up of the packaging from end customers and performs quality control, cleaning, and repair at their facilities.

Secondly, choosing packaging with recycled content is vital in establishing a circular plastics system. Such production process decreases the demand for virgin materials, allowing the plastic to remain in use and diverting it from landfills. This, in turn, minimizes the reliance on fossil fuels and improves the environmental impact of such packaging. Solutions made with recycled content maintain its high-quality while providing better value at a lower price tag.

Reorient & diversify your packaging

While recycling is one piece of the puzzle, a systemic transformation must be implemented to achieve a truly circular economy. Finding alternative materials to substitute virgin plastics is an essential objective in such a process, aiming to reduce the production of new plastics and promote circular management practices for end-of-life packaging.

Certain plastics cannot be eliminated or replaced with reusable alternatives, which poses a challenge due to their non-recyclable nature or tendency to contribute to littering. In such instances, a viable option could involve transitioning from conventional plastics to sustainable substitute materials, provided that there is scientific evidence based on life cycle assessments (LCAs) supporting their environmental sustainability5.

Working as one team to end plastic pollution

Collaboration and change across the entire supply chain are necessary in the fight against plastic pollution. Focusing on sustainable packaging made from substitute materials and creating a closed loop for plastic packaging are the areas with great potential to transform the market from linear to circular. Choosing a partner that designs packaging with the end-of-life in mind and offers shared and take-back solutions can lead to a more sustainable supply chain and divert the plastic waste out of the environment.

Nefab has been advocating the changes for over 40 years now. During that time, the company has been implementing new circular models and extending its reach by working with its clients on solutions that keep plastic circular. Get in touch to learn how we can support you.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our sustainable solutions.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials