Sustainable Packaging and Logistics Solutions for the Energy Industry

Specialized Protection for Your Critical Equipment

Specialized Protection for Your Critical Equipment

At Nefab, we understand the particular demands of the energy industry. We offer more than seven decades of expertise in packaging and logistics solutions, catering specifically to firms in Power Distribution, Power Generation, and Power Transmission.

Nefab delivers robust, end-to-end supply chain solutions engineered for your unique challenges.

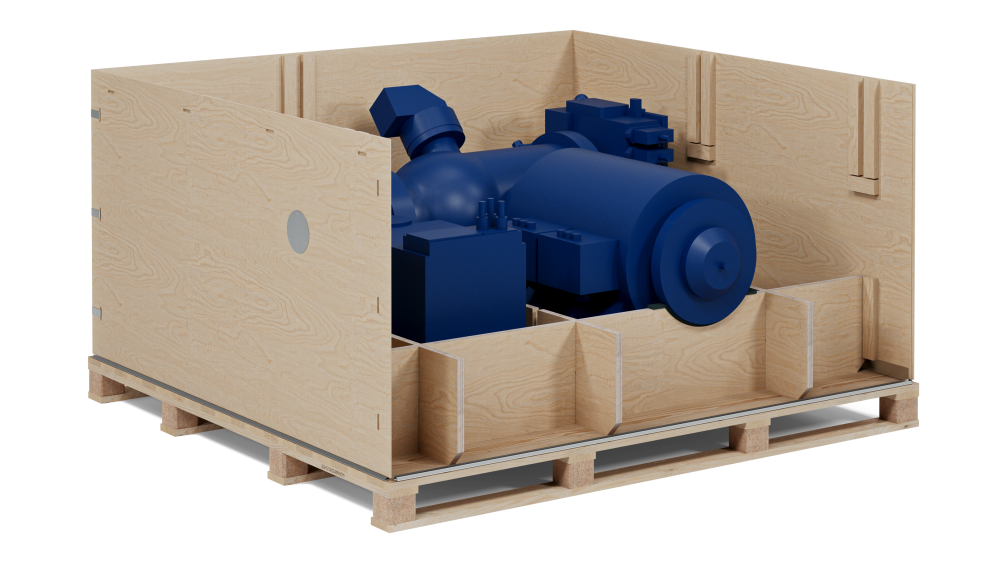

Tailored solutions accommodating complex equipment sizes and shapes, ensuring safety and compliance.

Consistent, regulated standards delivering end-to-end solutions wherever your business operates.

Sustainable packaging and logistics services that reduce both total cost and CO2 impact.

In the dynamic energy industry, challenges are inevitable. Nefab is equipped to tackle them head-on through:

Bridging international logistics complexities of managing major site installations.

From over sized turbines to fragile components, we have the necessary expertise and resources to handle even the most challenging transportation needs.

As experts in sustainable packaging, we aim to reduce both cost and the overall carbon footprint without compromising quality or safety.

Our engineered packaging solutions and optimized logistics services provide a holistic approach to tackling energy sector challenges. From material versatility to last-mile delivery, our solutions are designed to ensure the safe, timely arrival of your equipment while reducing costs and environmental impact.

Custom-engineered packaging solutions and materials including Plywood, Wood, Fiber, Plastics, Steel, and HD Corrugated, designed for your industry.

Returnable Packaging Management services and tools for streamlined delivery – making sure that you have the right item at the right time and place.

Offering Cost and CO2 Reduction Programs, aligning with your sustainability mandates.

Nefab is more than just a packaging provider - we also offer:

Consistency and quality are guaranteed, no matter where you operate.

We offer decades of specialized expertise dedicated to the energy sector's unique needs.

We implement packaging solutions that combine sustainability and cost savings.

Peter Bjelovuk

Global Segment Director Energy

Ready to revolutionize your supply chain? Connect with our team now to learn how Nefab’s global, tailored, and sustainable packaging and logistics solutions can power efficiency and resilience in your operations.

Contact us today to begin a conversation about a greener, leaner, and more cost-effective supply chain for your company.

Join us on a journey of saving resources and learn about the latest trends, solutions, and best practices in sustainable supply chain management and discover smarter ways to reduce environmental impact and boost cost efficiency.