Inner Packaging

Cushioning

Protect your products from sudden shock

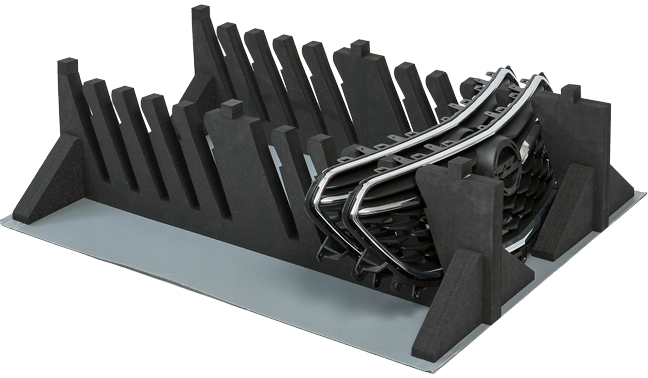

Foam cushioning is used to protect against shock and vibration. There are numerous different options to protect the goods and the final solution will be dependent on factors such as: product fragility, product weight, shipping and handling conditions, batch size and more. Nefab offers many foam materials and different solutions such as moulded foam, fabricated foam, foam-in-place, and foam profiles.

Cushioning Facts

Foam is widely used as protective packaging material and has unique shock absorbing abilities. There are basically four different materials (polymers) and two main manufacturing techniques that are used to meet required specifications. Foams can be either moulded or converted. Moulding demands more complicated tooling but is often an economically preferable choice for large quantities.

Cushioning Design

The quality and capabilities of the foam raw material is not only determined by the choice of polymer but also by its density and the manufacturing technique. Choice of material, quality, manufacturing method etc. decides the durability of foam products that can be made for both expendable and returnable applications. Different additives can be incorporated into the foam during the manufacturing process to obtain ESD protection or fire resistance. Some of the most common materials are Polyethylene, Polypropylene, Polystyrene, Polyurethane.

-

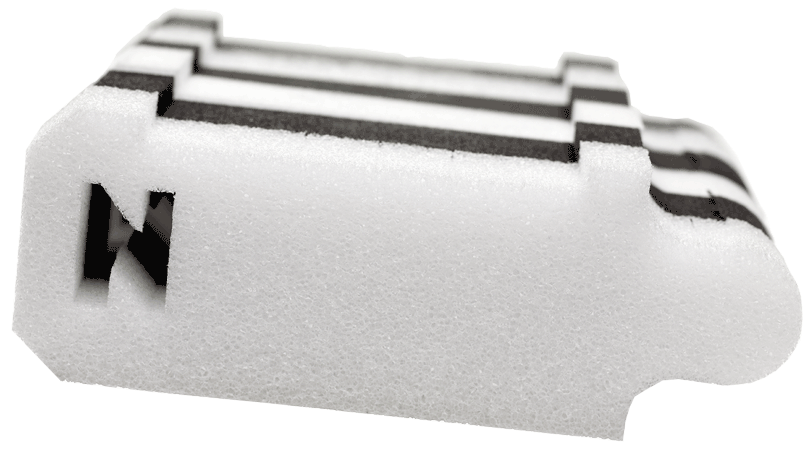

Fabricated Foam

Polyethleyne is moisture resistant with good multi-drop cushioning performance. We custom design, prototype and test foam packaging solutions for customers all over the world.

-

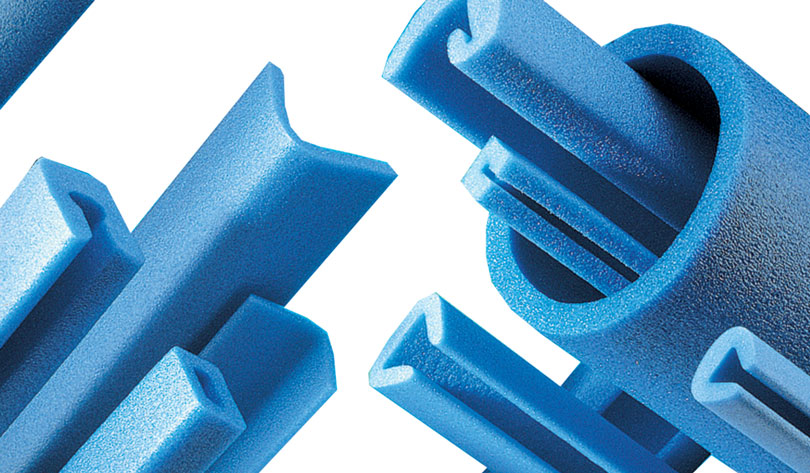

Foam Profiles

We offer a broad range of models with varying densities and shapes that are suitable for different applications.

-

Fiber-based Foam

Nefab's WoodFoam is a recyclable foam for lightweight products. It is a sustainable and healthy alternative to plastic-based and PU foam: fiber-based, 100% isocyanate-free, repulpable and recyclable as paper.

Get in touch

To learn more about cushioning solutions, please contact us today.