By 2050, the global population is expected to generate 3.40 billion tons of waste annually, increasing drastically from today’s 2.01 billion tons. Additionally, more than 33% of this waste is mismanaged and leaks through open dumping or burning into the environment.

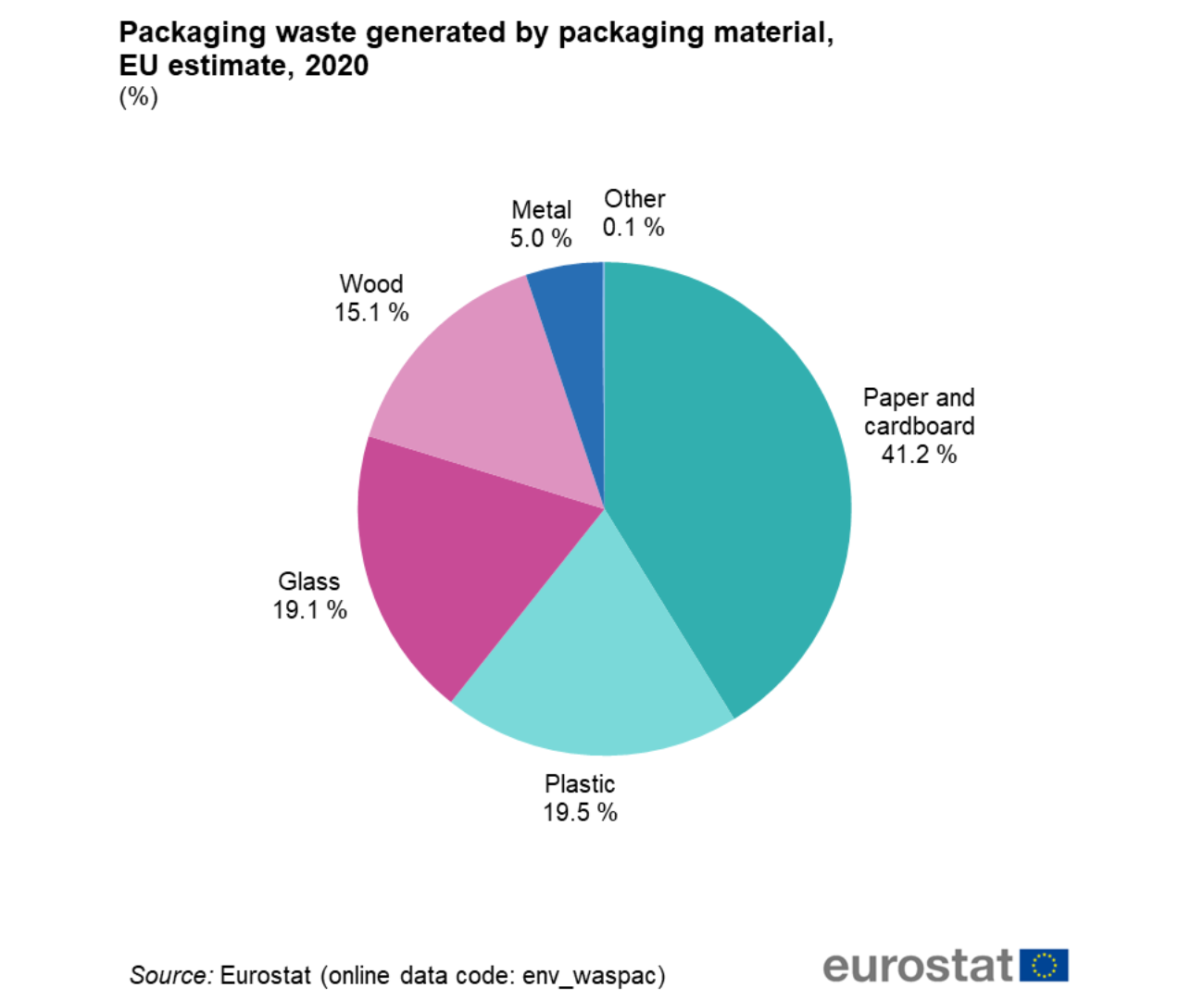

The situation varies from region to region. In Europe, for instance, paper and cardboard remained the main packaging waste material in European Union with over 32.7 million tons disposed in 2020, followed by plastic and glass with 15.5 and 15.1 million tons respectively. On average 80.2% of total waste is recovered in the EU (compared to a 60% threshold set by the Packaging Waste Directive) and average of 64.4% gets recycled (55% threshold under the PWD) (europa.eu). In North America, on the other hand, out of 82.2 million tons of generated packaging waste 23% consisted of paper and paperboard and 12% came from plastic, with total recycling rate around 53.9% (epa.gov) On the other side of the globe, the Asia-Pacific region will be responsible for over 70% of global mismanaged plastic waste by 2025 (statista).

- Sustainability

- Corporate News

Mitigating packaging waste

We live in a world where we are producing more waste than we can handle.

According to Eurostat, paper and cardboard remained the main packaging waste material in European Union (41.2%), followed by plastic (19.5%), glass (19.1), wood (15.1) and metal (5%).

According to Eurostat, paper and cardboard remained the main packaging waste material in European Union (41.2%), followed by plastic (19.5%), glass (19.1), wood (15.1) and metal (5%).

Following the latest McKinsey’s report, the industry must follow two routes to end packaging waste crisis. First is to reduce the waste pollution by improving the management and collection systems. Second is to create circular loops by switching to sustainable packaging materials (McKinsey). As part of the Global Compact, Nefab shares this commitment to making our supply chain more sustainable and reducing waste in collaboration with our customers. Continue reading to learn more about how to mitigate these risks and build sustainable supply chains.

Detrimental impact of waste disposal

The generated waste has been detrimental to our environment for quite some time. It has been estimated that CO₂ emissions from materials used for packaging exceeds those caused by global aviation (The conversation). In case of plastic packaging, for example, manufacturing one kilogram of plastic emits 3.5 kg of CO₂ into the atmosphere. The lack of sustainable and effective waste collection and recycling systems result in dumping 49% of global waste to open landfills where they release methane gas, which is heating up our planet (Earth Day).

However, not only the ecosystem is at risk through our inaction. Packaging waste is polluting marine biodiversity as its floating fragments, dumped into the oceans, are either being consumed by thousands of species or release poisonous chemicals into the marine environment. On the other hand, the harmful emissions produced from waste disposal and burning lead to various diseases such as asthma, birth defects, cancer, cardiovascular diseases, childhood cancer, COPD, infectious diseases, low birth rate and preterm delivery (Earth Day).

Shifting the mindset from linear to circular

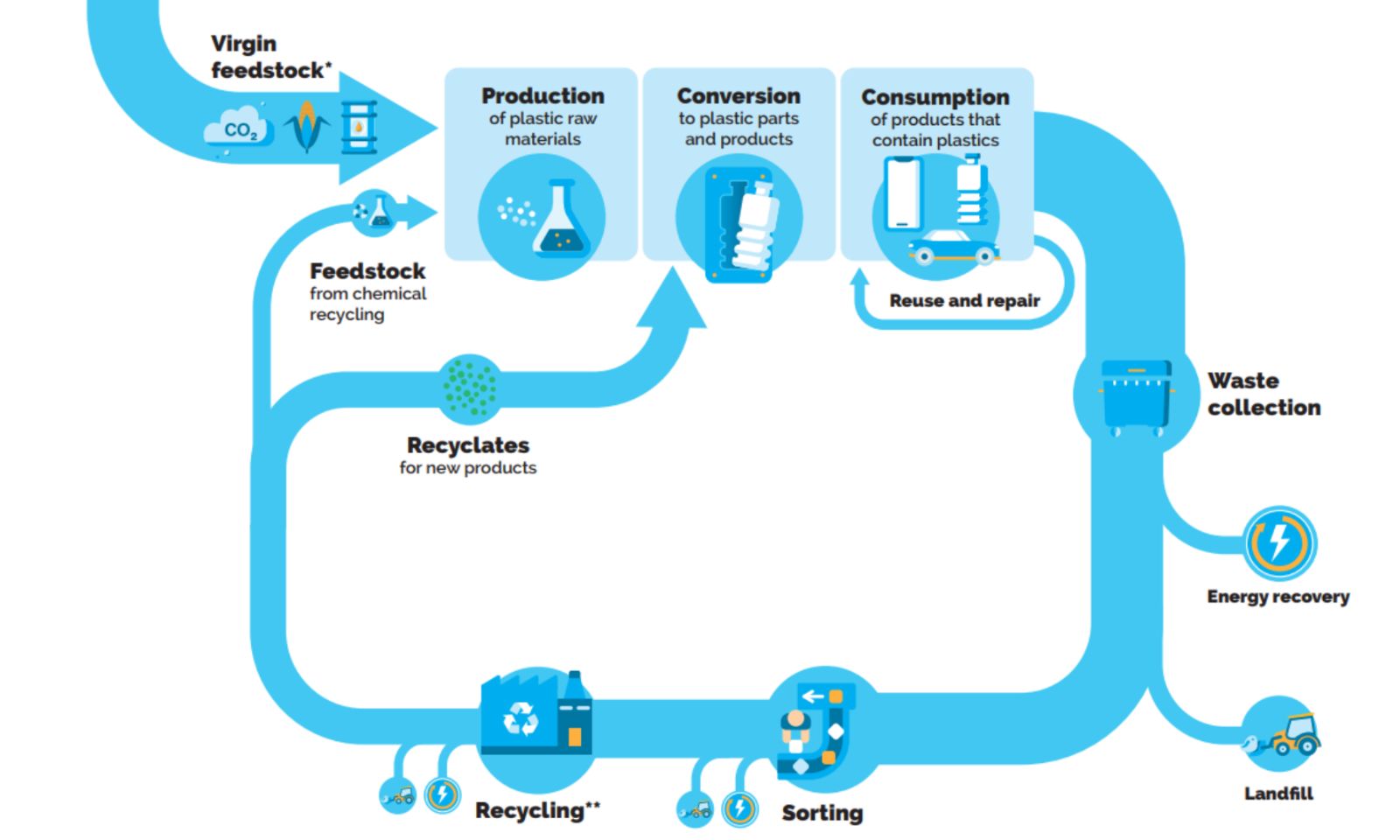

Another challenge is that most of the packaging waste doesn’t get recycled. Most often, waste management infrastructures lack the functionality to deal with different formats or mix of materials within the packaging, which lowers the overall quality of the recycled material. In 2019, the global production and incineration of plastic packaging emitted more than 850 million metric tons of greenhouse gases — equal to the emissions from 189 five-hundred-megawatt coal power plants (Zerowaste).

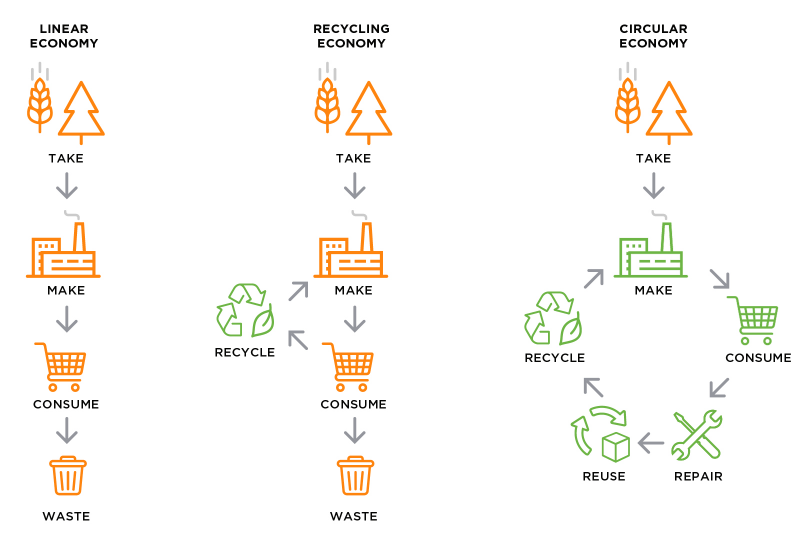

However, by shifting the mindset from linear to circular, we can reform packaging and supply chain industries. The new approach follow the three principles (3Rs): (1) eliminate waste and pollution (2) circulate products and materials (3) regenerate nature (you can learn more about it here). Many products could be easily circulated by being repaired, reused or refurbished, and as a last resort, recycled. The market demand for recycled plastics and plastic circularity has also been accelerating.

The concept of circular economy is gaining in popularity, as a natural and logical step to eliminate packaging waste and pollution.

The concept of circular economy is gaining in popularity, as a natural and logical step to eliminate packaging waste and pollution.

Strenghthening circular loops to prevent leakage

Unfortunately, circularity alone won’t stop packaging waste leaking into the environment. Global economies still need to have proper waste management systems for the plastic and other packaging materials. That is why the introduction of the circular design rules (reduce, reuse, recycle) is only one way to end the global packaging waste crisis.

Another one is to extend these rules by adding, i.e., repurposing (into different roles), re-gifting (i.e. donating to other companies that can use them further), and repairing (components or whole devices). It is also important to underline that waste can be reused both internally and externally, thus translating into an economic gain for the company. For example, scraps or offcuts can be reused in internal production of other materials, while the total waste can be sold to a third party for recycling or conversion into new materials that can be resources at a lower price.

Final call to clean up the mess

This is why it is crucial to rethink and redesign packaging to make it toxic-free, circular by design, and contributing to regenerating ecosystems instead of polluting them. In fact, by switching to circular design, it is possible to eliminate 75% of the waste that is currently being exported, thus mitigate climate change impact through the reduction of carbon footprints (Zerowaste).

As a principle, packaging that cannot be safely used, reused, and recycled at the end of its life should not be produced or placed in the market in the first place. The solution to stop this packaging pollution chain is logical: the less packaging we produce, use, and discard, and the less materials we extract, the better for our environment and society. At Nefab, by innovating together with our customers we are finding new ways to save resources in supply chains.

The circular model for plastics closed loop where the used plastics generate value from waste and avoid sending recoverable material to landfill (Plastic Europe).

Want to learn more?

GET IN TOUCH

Contact us to learn more about our sustainable solutions.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials