- News & Insights

- 2023

- Warehouse Management System: why do you need one and how it can optimize your business?

- Sustainability

- Innovation

- Corporate News

News & Insights

Warehouse Management System

Why do you need one and how it can optimize your business?

The growth of e-commerce has led to a proliferation of stock units, and there’s an ever-growing need to satisfy customer demands...

The growth of e-commerce has led to a proliferation of stock units, and there’s an ever-growing need to satisfy customer demands by offering super-fast fulfillment. With more and more new automation systems launching on the market every year, operation leaders must keep pace with new technologies and predict what impact they can generate on their business. Worldwide, companies spend an estimated 350 billion USD a year on warehousing, and that number grows each year. As a result, the global warehouse management system (WMS) market is projected to grow from 14,517 million USD in 2022 to 51,360 million USD by 2030, growing at a CAGR of 17.3%.

However, with so many different types of WMS available, it can be a challenge to choose the right solution for your business. What matters even more is the right service provider, a one-stop shop that delivers a uniform and standardized quality of service level across the globe to ensure that your operations run smoothly. Follow along as we outline the three main aspects to keep in mind when shopping around for the right partner.

AUTOMATE YOUR WAREHOUSE OPERATIONS TO A NEW LEVEL

Simply put, WMS is a type of software that is widely used in the manufacturing industries because it easily tracks all materials and goods as they come in and out of the warehouse. What is more, WMS helps optimize various warehouse processes as it creates systems to streamline how workers pick and pack orders, tracks Stock-Keeping-Units (SKUs) entering and leaving the warehouse, and more. Since the WMS holds all the information in one place, it allows you to quickly identify the available product when a new order comes in and simplifies the shipping preparation.

By automating this process, you save a great deal of time and resources, not to mention eliminate human errors. What is more, a warehouse management system helps you speed up your order fulfillment and can keep track of what is selling well. As a result, all this valuable information can help you optimize the way you set up your warehouse, make sure you are well stocked before busy periods, and even locate the best-selling products next to the loading dock or the packing area to make them more accessible to the staff.

ENHANCE PRODUCTIVITY WITH A SCALABLE AND FLEXIBLE WMS

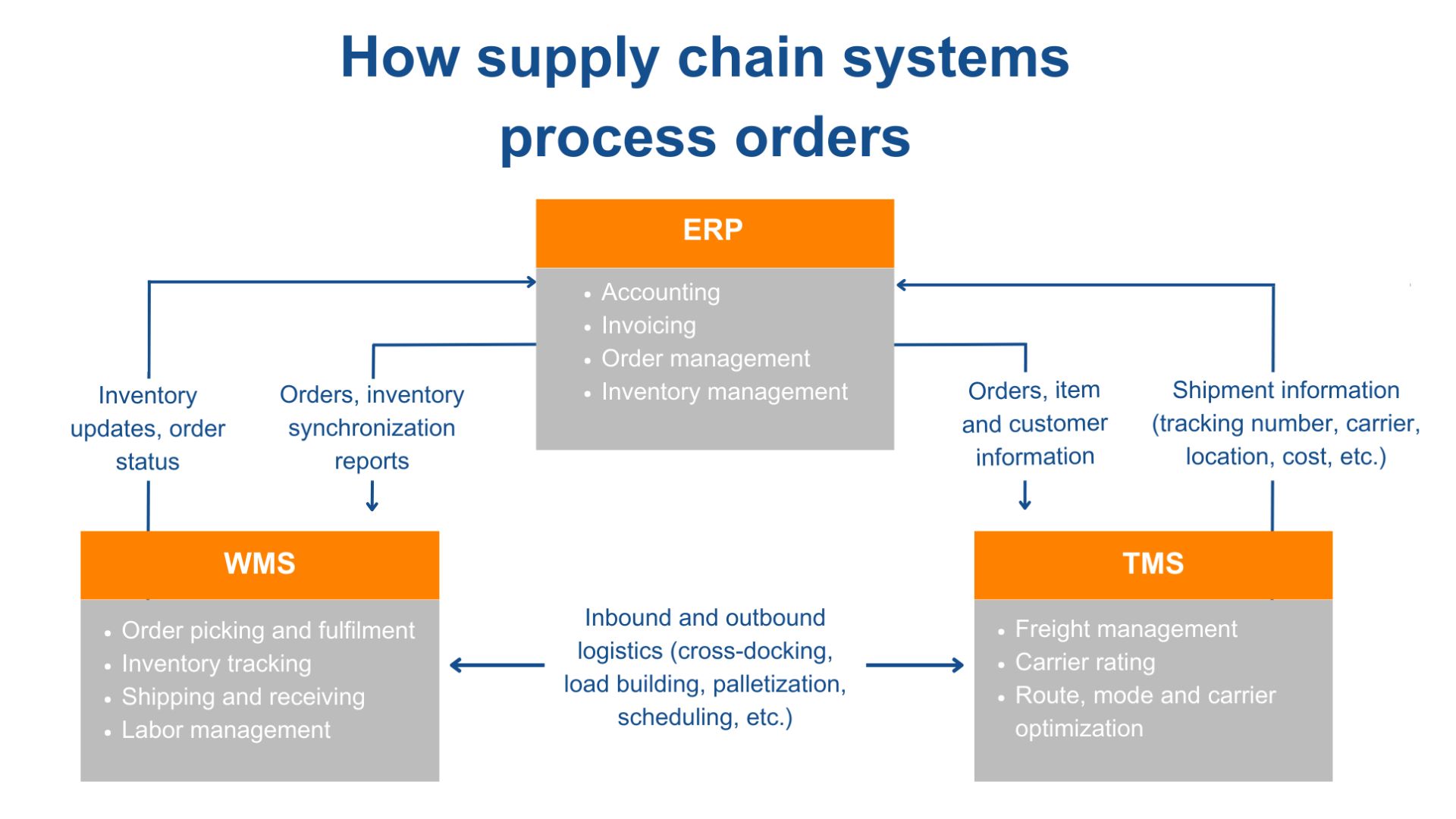

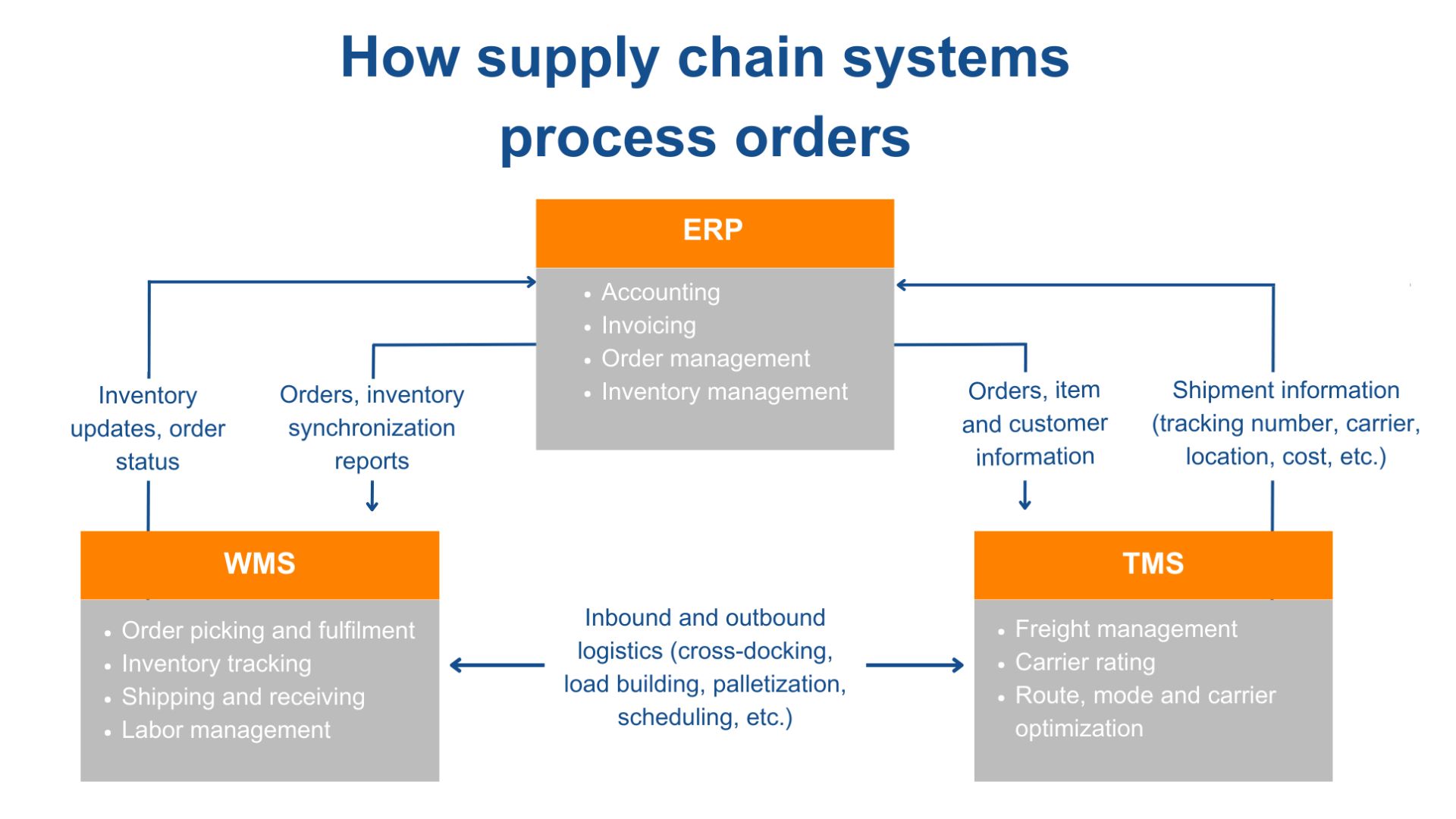

There are two types of warehouse management software you should consider – an integrated WMS and a standalone WMS. The first one is normally an add-on from your existing Enterprise Resource planning provider (EPR), which handles invoicing, accounting, and tracking inventory (without picking, packing, and shipping). By integrating everything into one system, it’s much easier to keep track of which orders are best to invest in. A standalone system, on the other hand, has usually more features focused on warehouse processes, like advanced reporting, that can help you level up you warehouse services. However, it might have limited functionality for other aspects of your business, such as inventory or accounting.

When choosing the right WMS for your operations, you should consider its scalability and flexibility to adapt to the growing needs of your business. The initial investment might seem like a lot to handle, but with the rapidly evolving nature of your business, you need a system that can help you monitor performance over time and forecast demand in advance before it’s time to restock. To speed up the process and enhance your operations, you can opt for a solution that seamlessly integrates with your current ERP system. Remember that maintaining and managing two separate software systems in-house might be a headache, but there are cloud-based options that are typically charged on a subscription basis and hosted by external providers that guarantee 24/7 service and maintenance. Finally, choose the system that ensures maximum productivity by reducing the resources needed to operate WMS. This way, your staff can focus on other priorities than tracking lost stock units during shipping and packing. This is likely one of the main reasons why most companies without a WMS are considering implementing one.

The initial investment might seem like a lot to handle, but the results might exceed expectations. One example of the recent world-class WMS implementations was a project done by Nefab in Finland. In the beginning of 2020, within just 3 months during the strongest Covid restrictions, the team successfully implemented WMS which significantly reduced CO2 and costs as well as improved efficiencies in operations and transportation.

The initial investment might seem like a lot to handle, but the results might exceed expectations. One example of the recent world-class WMS implementations was a project done by Nefab in Finland. In the beginning of 2020, within just 3 months during the strongest Covid restrictions, the team successfully implemented WMS which significantly reduced CO2 and costs as well as improved efficiencies in operations and transportation.

JOIN FORCES WITH THE RIGHT PARTNER

Regardless of the type of software you chose, with WMS you gain more control over inventory management, easily meet demand while optimizing storage and avoid overpaying for deadstock. Thanks to its scalability, WMS meets both small and large organizations’ requirements as it covers a wide range of services, depending on individual preferences. Keeping in mind the size of your business and the available budget, it’s worth considering the investment at various stages of your supply chain process optimization. In the long-term partnering with the right WMS provider helps you save costs, time, and resources, while optimizing your logistics process and providing visibility into the supply chain.

At Nefab we got you covered and offer customized contract logistics services. Depending on the scale and complexity of your warehouse operations, the company lets you choose one of their proven warehouse management systems or uses the customers’ own systems. Nefab also leverages the technology-agnostic track and trace software to provide full visibility of your stock from 110 countries around the globe, saving you up to 95% costs of implementing new devices. Thanks to Nefab’s dedicated processes and individual approach, the team can help optimize your supply chains today and tomorrow under one roof.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials