As the world strives to achieve net zero by 2050, the global push for minerals - which are essential components for clean energy technologies, such as electric vehicle batteries or wind turbines - is fueling a notable rise in resource extraction. 1 Projections from the UN suggest that mineral harvesting is anticipated to increase by an additional 60% by 2060. 2 To efficiently extract and process natural resources, the mining industry heavily depends on advanced machinery, making the equipment sector essential to the industry's overall success. 3 The equipment industry, however, is facing rapidly escalating costs for reasons such as an uncertain economy and supply-demand imbalances. 4 In addition, stringent environmental regulations, and investor and stakeholder expectations are pushing the industry to reduce its impact, further complicating the operational landscape. 5

These challenges, however, present unique opportunities. “Mining equipment companies should look closer at their supply chains as rethinking your packaging and logistics operation can lead to significant improvements, such as increased operational efficiencies, reduced costs, and enhanced sustainability. By embracing these changes, the mining equipment industry can overcome current obstacles and pave the way for a more sustainable future,” says Inna Stint, Mining and Construction Segment Director at Nefab. Read further as we explore how strategic adjustments in the supply chain can drive the mining equipment sector towards greater efficiency and environmental stewardship.

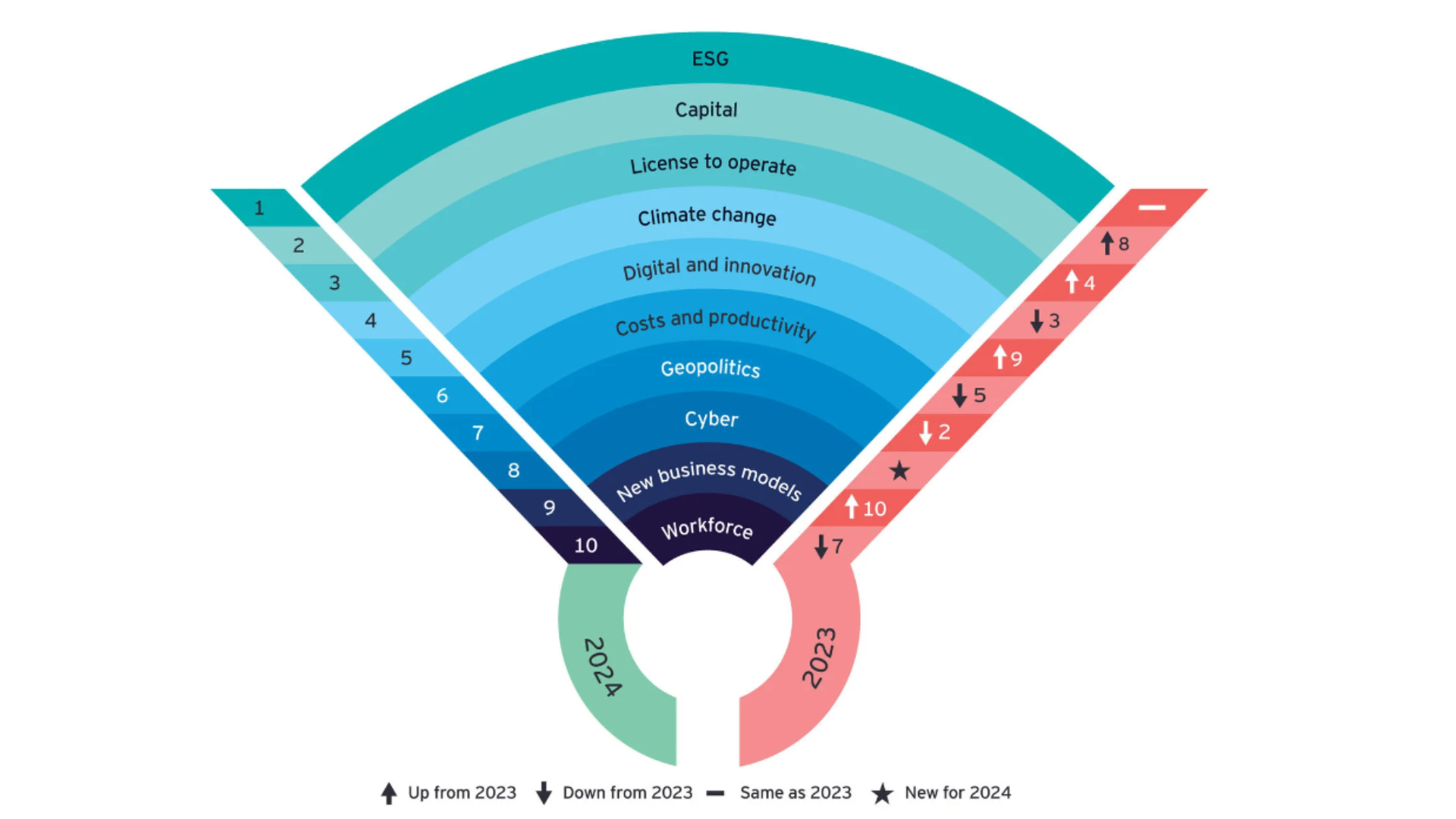

ESG remains a top priority for mining and metal companies. Source: EY6

Bundling Services Boosts Operational Efficiency

It goes without saying that reliable equipment is the backbone of efficient and safe mineral extraction processes. Proper maintenance of the mining machinery helps to prevent accidents and keep equipment in good condition, lowering risks for hardworking miners. The halting of operations due to any malfunction can also result in significant losses, with some assessments suggesting a cost of $130,000 per hour for each equipment failure incident. 7 Fortunately, mining equipment companies have avenues to protect themselves from the worst-case scenario. “By partnering with a contract logistics service provider, businesses can focus on core operations while ensuring the distribution center is managed efficiently. On-time delivery is critical, especially for spare and wear parts, as availability at the exact needed moment prevents operational delays and downtime,” explains Inna Stint.

Maintenance and servicing components for mining equipment vary in size and shape, ranging from small screws to e.g. large buckets for crushers. Transporting these components across the globe is a delicate and expensive endeavor where safety and cost-optimization are paramount. This is where optimized packaging design comes into play. Customizing the packaging to suit the transported product prevents “transporting air” and enhances container fill rates. Switching to alternative packaging materials, e.g., fiber-based or plywood solutions, reduces the weight of a shipment. Optimizing packaging is a fine balance between the use of material and the protection level, where the winning formula provides optimal packaging and maximum protection. Such packaging is not only safer and easier to assemble but also facilitates smoother handling throughout the logistical flow. To ensure seamless operations, synchronization between packaging and warehouse and distribution management is essential, making it imperative to partner with a company offering both services under one roof.

Choosing a one-stop-shop partner for your packaging and warehouse services ensures seamless operations and right-on-time delivery of servicing components for mining equipment.

Enhancing Sustainability with Alternative Packaging Materials

The industry’s focus on sustainability encompasses all aspects of business operations, including the supply chains. “People often don't realize that utilizing optimized packaging and smart logistics services can be powerful tools for cutting down CO2-eq emissions and reducing waste,” explains Inna Stint. There's a growing demand for biodegradable packaging, particularly for deliveries to remote areas. To meet this need, packaging should be made entirely from biodegradable materials such as fiber-based solutions. This helps ensure that the packaging breaks down naturally after use, without causing harm to the environment, which is in line with the industry's sustainability goals.

For many companies, one of the greatest hurdles is figuring out how to assess and track progress effectively. Establishing a baseline for measuring positive advancements might be challenging, yet it's crucial for establishing credibility and ensuring the integrity of such valuations. With the sector transitioning to mandatory reporting, companies are increasingly focused on how to disclose and report their efforts.8 Life Cycle Analysis tools are invaluable for showcasing the impact of changes and assessing both environmental and financial effects. Nefab has led the change in this field for over a decade with its certified GreenCalc™ tool, utilizing data to optimize different aspects of the supply chain to find the most resource-friendly solution. It not only measures cost savings but also highlights the environmental advantages of transitioning to greener packaging and logistics solutions.

Maintaining quality of service through strategic partnerships

Cooperating with a single partner for both packaging and warehousing services on a global scale is essential for maintaining a unified standard of service. This collaboration not only streamlines operations but also strengthens client relationships by providing a reliable, one-point-of-contact system. “Ensuring uniform quality across all local distribution centers reinforces brand integrity and customer satisfaction, making it easier to manage logistics and uphold service excellence worldwide,” says Inna Stint. She adds, “At Nefab, our commitment goes beyond just delivering quality; we're forging long-lasting partnerships and pioneering sustainability in the mining and construction sector, driving positive change one step at a time.”