- News & Insights

- 2023

- Reasons why packaging design should be considered during the product development

News & Insights

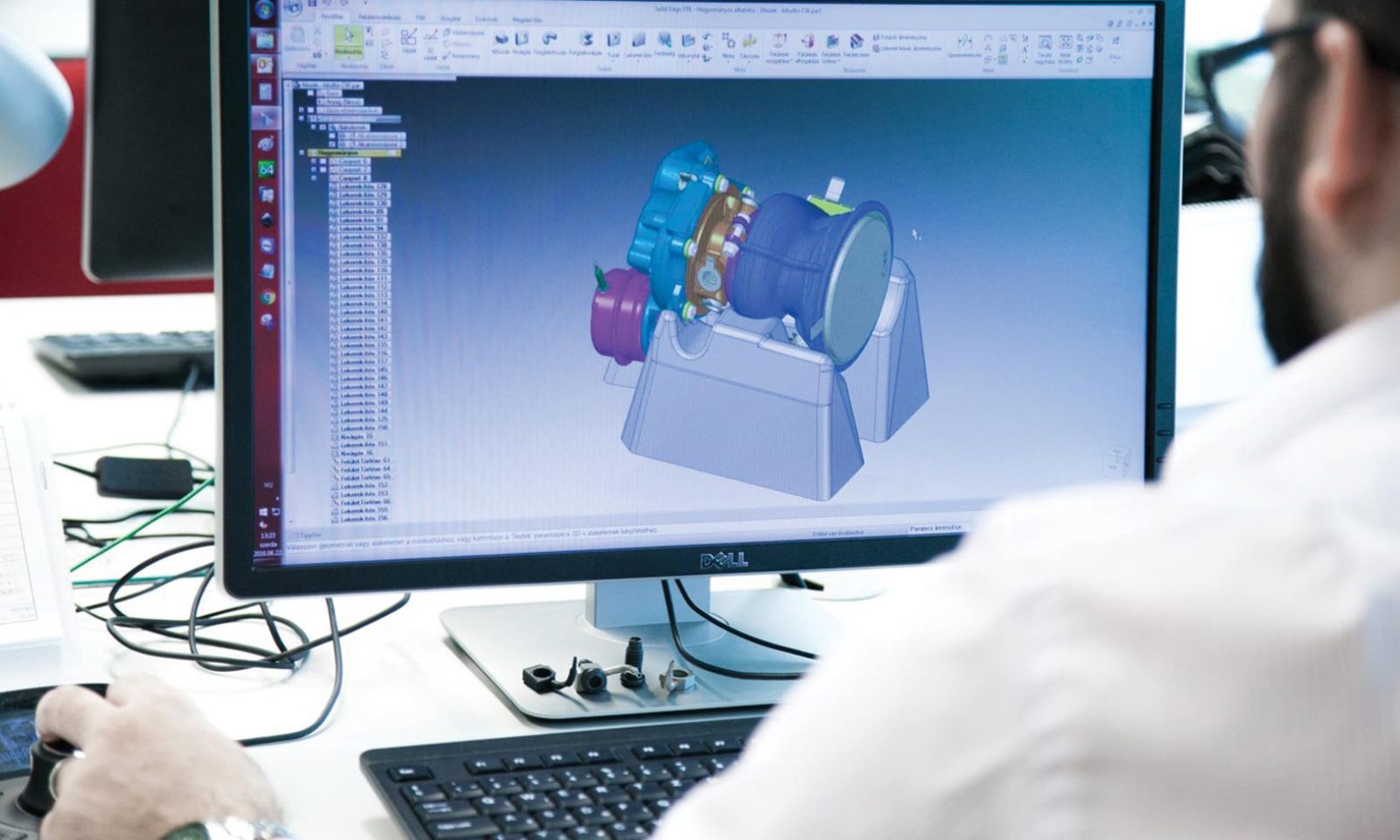

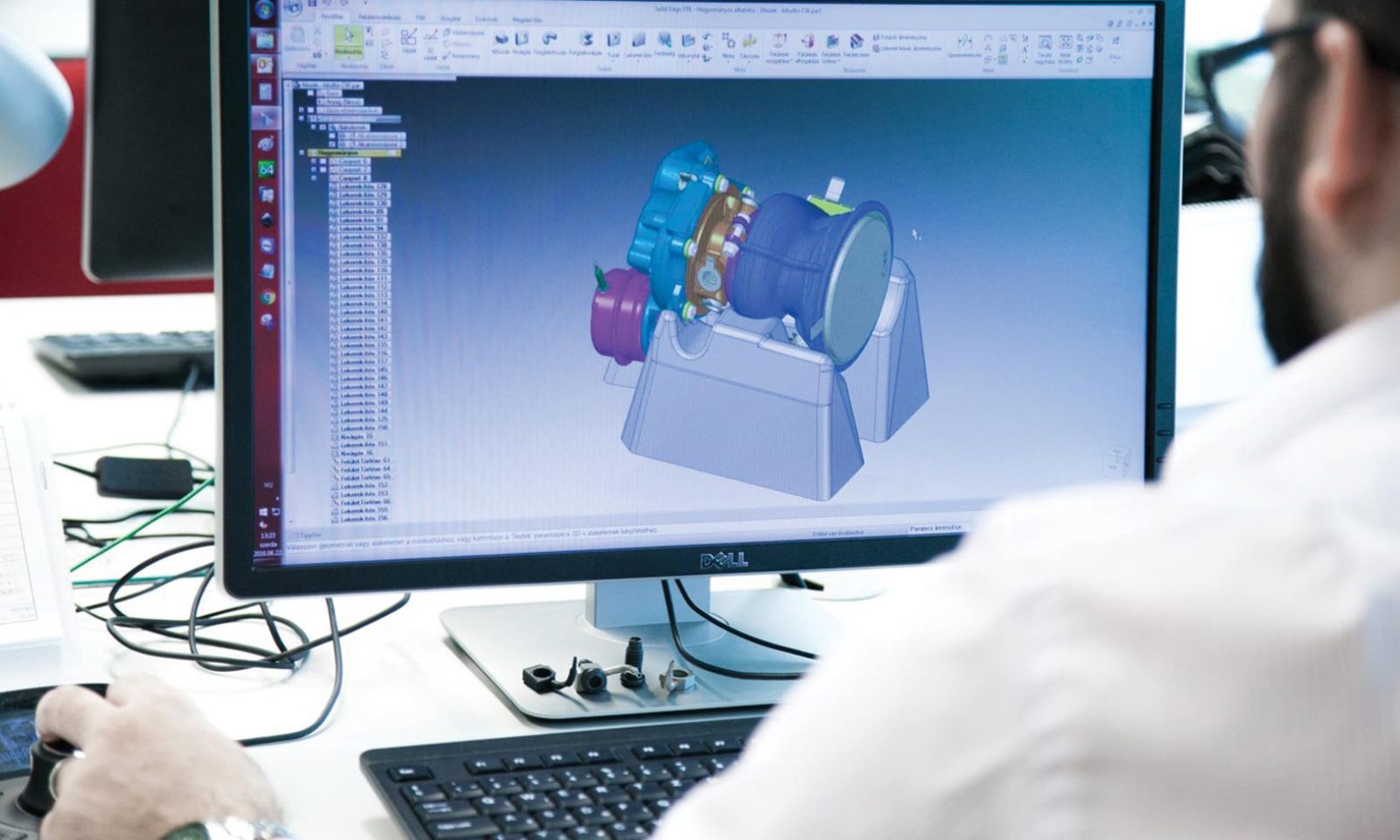

Product development

Reasons why packaging design should be considered during the product development

Packaging design is the often overlooked stage in product development that can make or break your launch

Optimizing your packaging design early on can save costs and maintain product quality during its logistical journey. Learn how a comprehensive packaging strategy can ensure your final design withstands the supply chain cycle

In fact, to optimize the costs and quality of shipment, it is important to consider this stage early on to avoid last-minute product changes. The hard truth is that there is no one-size-fits-all solution here and every product, from a microprocessor to an airplane part, requires a different approach. Taking a comprehensive strategy to packaging design and testing will pay off in balancing costs while maintaining product quality during its logistical journey, guaranteeing that the final design can withstand the supply chain cycle with all its weaknesses. Read on to find out how.

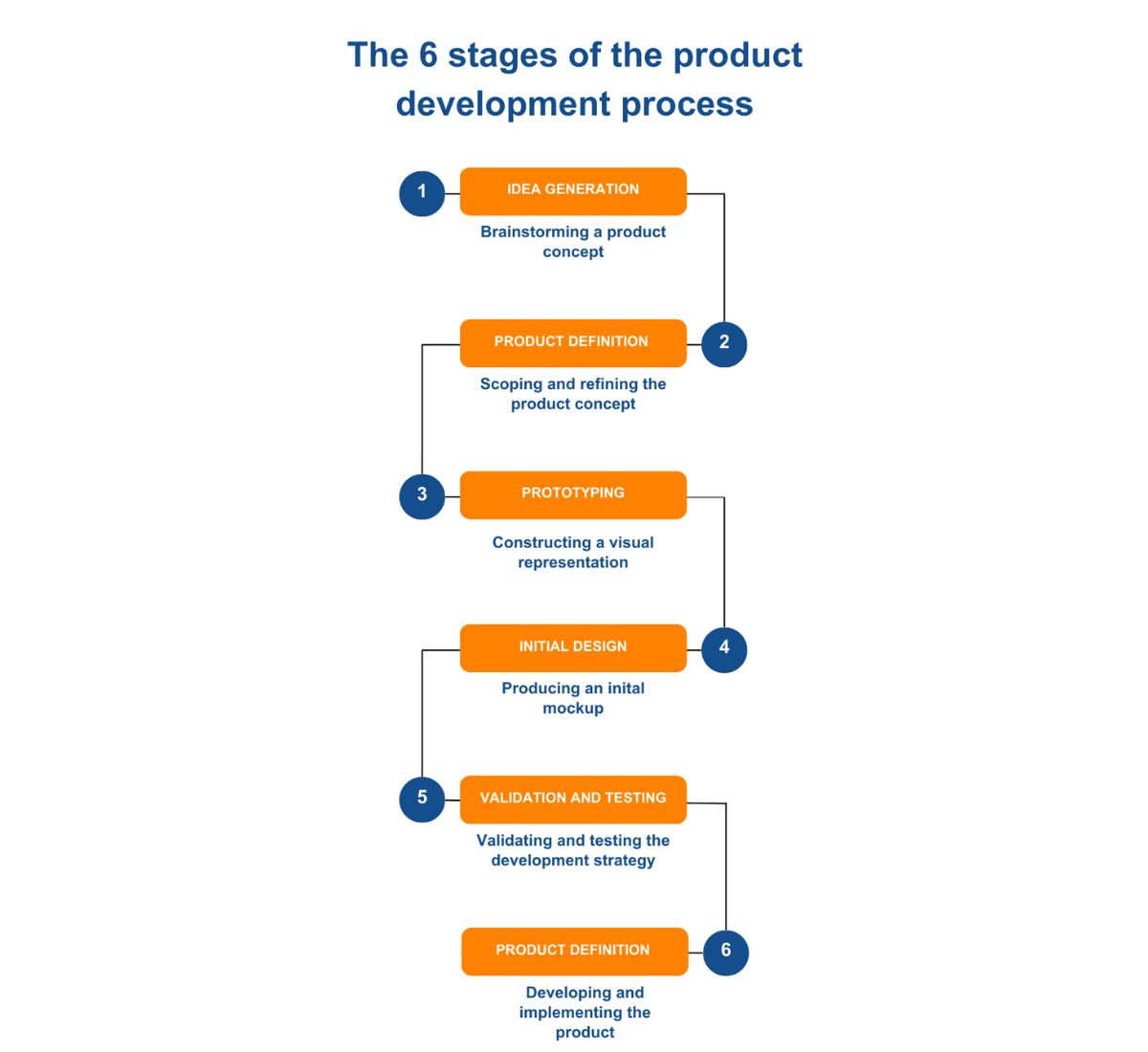

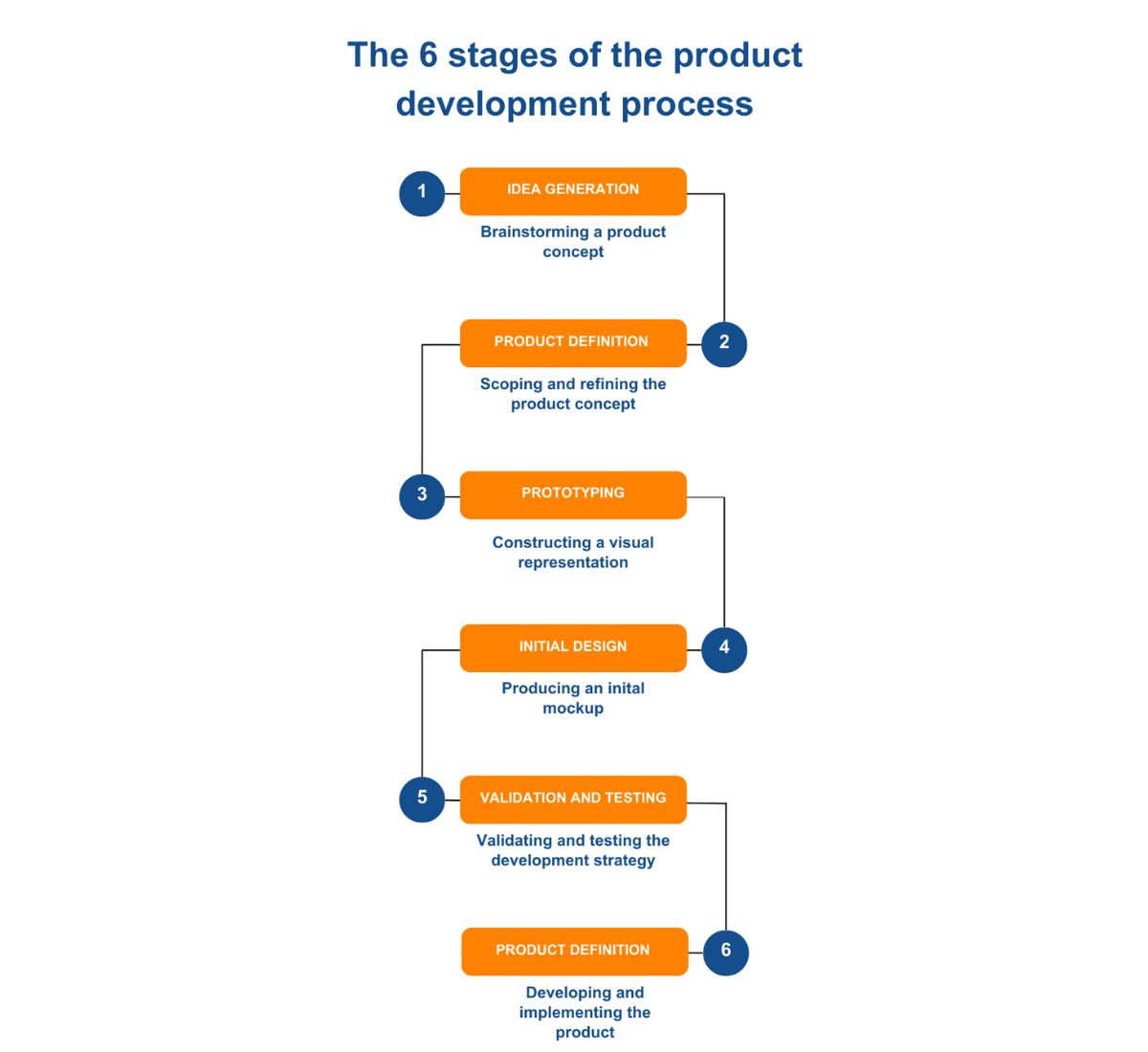

Packaging design is usually the last stage of product development process (after stage 5), however Nefab encourages its customers to take into consideration packaging design as soon as stage 2 (Product definition). This way you can optimize packaging performance, improve the product, and generate environmental and material savings.

Packaging design is usually the last stage of product development process (after stage 5), however Nefab encourages its customers to take into consideration packaging design as soon as stage 2 (Product definition). This way you can optimize packaging performance, improve the product, and generate environmental and material savings.

Dropping, lifting, pitching, taxing, and accelerating – a product logistical journey is never a smooth one. Prone to shocks or vibrations during transportation, it requires tailored packaging to mitigate the potential damage and environmental impact. That is why it is highly recommended to first - involve packaging design in the early stages of the product’s development and second – monitor the product’s performance during the testing phase. This crucial step shortens the time required to design the optimal solution, saving resources, and providing invaluable insights to improve the overall packaging quality.

Understand product’s fragility and ensure its optimal protection

This process involves a deep analysis of the products’ vulnerabilities to determine what type of packaging is best suited for its transportation. The fragility level, referring to the maximum shock that a product can withstand without suffering damage, is defined here through test data to avoid overestimating the product’s shock absorbance (read more here). Knowing the products’ sensitivity to mechanical constraints and climate resistance will help you determine the level of protection it requires (from foam cushioning to cardboard fillers) and, consequently, the overall packaging costs. If chosen correctly, your packaging will help you avoid overpacking and provide optimal protection to absorb potential damage.

Safeguard your product through packaging testing

Once packaging has been designed and developed, it is necessary to perform preliminary testing of the packaging prototype. Many companies skip this stage, hoping to save time and resources, however, ignoring the last and the most crucial phase may result in many side effects. In fact, only thorough testing can validate that products will withstand the various challenges during the product’s transportation and storage.

There are many standards and tests available for selecting the most cost-effective and sustainable packaging solution that ensures proper protection. To choose the right one, it is crucial to analyze packaging and products’ pain points, as well as consider different transportation hazards they may face. After each round of testing, improvements should be made until the packaging is ready for the final release test. As a certified packaging design and testing partner, Nefab incorporates these standards in all its worldwide testing facilities every day (read more here).

As a certified packaging design and testing partner, Nefab incorporates many international standards in all its testing facilities every day

As a certified packaging design and testing partner, Nefab incorporates many international standards in all its testing facilities every day

Save more by thinking smart

According to Nefab’s experience, if the packaging is considered at the last stage of product’s design, the savings can amount to approximately 20%, However, involving packaging engineers at an earlier stage allows for up to 60% savings measured in thousands of dollars. In addition, this simple change offers the potential sustainability improvements which are primarily associated with reductions in CO2 emissions through less diesel fuel burned per unit,thanks to better utilization of containers and trucks (McKinsey).

Teaming up with packaging engineers can also benefit in using their knowledge of both international and country-specific packaging standards. This ensures that products move swiftly through the global supply chain, avoiding potential customs and tax issues.

Strive for success with the right partner

Remember that developing truly sustainable products and packaging can only work through close collaboration between product designers and packaging engineers. Regardless of the size and value, all products need the right protection against shock, vibration, and climate constraints since the transportation journey to the destination can be unpredictable.

Rest assured that by involving packaging design in the early stages of product development, you will be able to select the most cost-effective and sustainable packaging solution that ensures proper protection. At Nefab, we offer the experience and know-how of more than 200 packaging engineers and 5 test labs located globally to find smarter ways to reduce the environmental impact. Together, we can pave the way for a future with less packaging waste for our customers, for society, and the environment.

GET IN TOUCH

Contact us to learn more about our sustainable solutions driving supply chains forward.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials