- News & Insights

- 2023

- Top three trends in logistics & supply chain management in 2023

News & Insights

Analyzing Logistics Trends

Top three trends in logistics & supply chain management in 2023

Companies are accelerating their efforts to diversify and localize their supply networks, while investing more and more into advanced technologies for supply chain planning, execution, and risk management

Four years on from the start of the COVID-19 pandemic, risk and resilience still dominate the supply chain. Persistent inflation, the impact of some 11 interest rate hikes on the cost of capital and subsequent business investment, declining imports, and a massive inventory overhang from pre-pandemic ordering all conspired to flip that expectation on its head as 2023 wheezed to a close.1 Overall, the expectations among shippers, carriers, and logistics service providers is for little to no recovery and a new year saddled with many of the same challenges and issues they faced in 2023.

To counteract that, according to latest McKinsey survey, companies are accelerating their efforts to diversify and localize their supply networks, while investing more and more into advanced technologies for supply chain planning, execution, and risk management.2 To end the year on a more positive note, we summarized the key trends that were driving the industry in the past 12 months and will help the players power through the difficult transition into the new year.

Digitalization and Automation

In our fast-paced world, digitalization and automation have become the true MVPs of logistics. Smart warehouses with robots zipping around, optimizing every inch of space, and reducing human error is a common view. The rise of IoT, Artificial Intelligence, and Big Data analytics is transforming supply chains into highly efficient, data-driven ecosystems.3 According to McKinsey survey, this year the share of respondents who have implemented dashboards for end-to-end visibility has jumped significantly to 79 percent, and attention has switched firmly to improving supply chain planning processes. That might be because improved visibility has revealed weaknesses in the underlying processes companies use to manage their supply chains: 71 percent of respondents say that they expect to revise their current planning processes and governance over the next three years.4

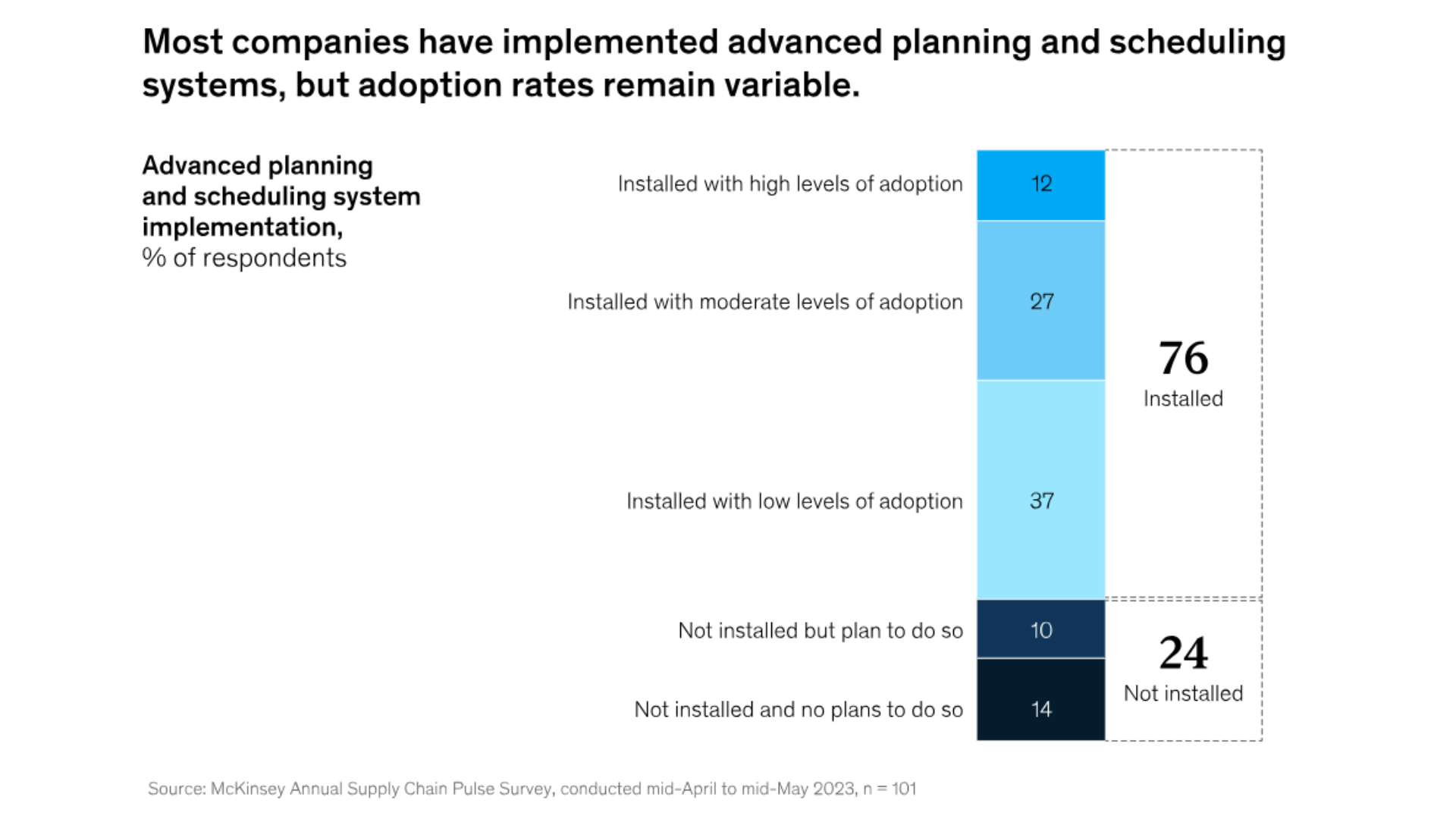

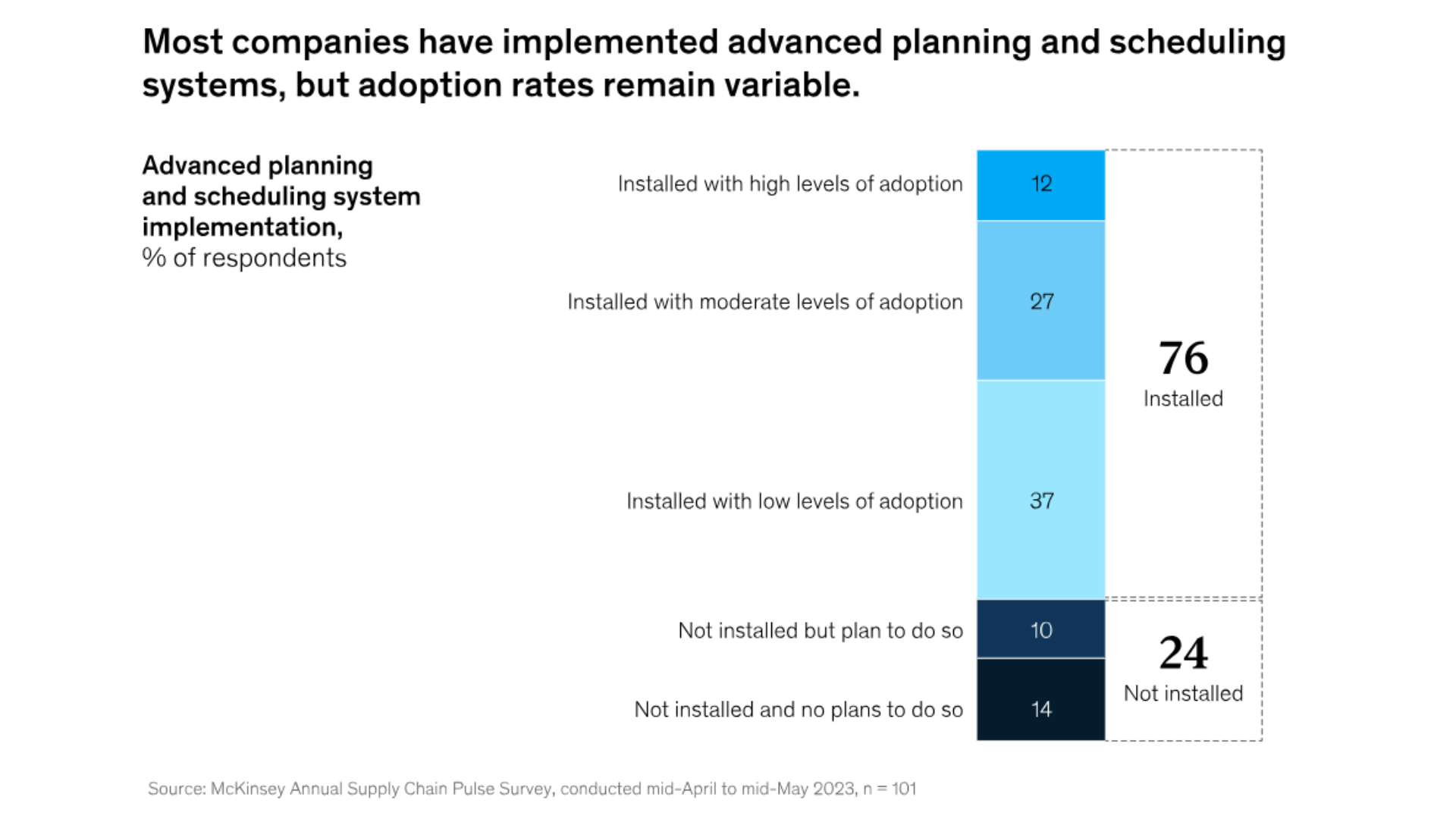

According to the latest McKinsey’s survey, 76% of logistic companies installed an advanced planning and scheduling system in 2023 to boost their operations.5

Resilience and Risk Management

Preparing for the unexpected has become a daily motto of the supply chain players in the past years. Environmental disasters, health crises and geopolitical instabilities have all had extensive effects on global networks.6 The only way for companies to proactively manage the risks and prepare contingency plans is to enhance supply chain visibility. Using real-time tracking, predictive analytics and Life Cycle Analysis programmes minimize the possibility of disruptions and errors. In turn, this boost trusts between business and customers and saves time and resources.

By analyzing customers’ supply chains using Life Cycle Analysis tools, like GreenCalc™, you can calculate exactly how much CO2-eq emissions and money they spend using their existing solutions. The system then leverages the data and optimizes different aspects of the packaging to find the most resource-friendly solution.

Sustainability: A Driving Force of Logistics

Finally, sustainability and “green” logistics are no longer an option. Companies are adopting eco-friendly practices, from using pooling and returnable management systems, to reducing packaging waste and optimizing transportation routes to minimize their environmental footprint. In addition, waste reduction and recycling programs are implemented on a more massive scale in logistics facilities because they are seen as a proactive and sustainable approach that contributes to environmental protection, resource conservation, cost savings, and improved corporate responsibility.

By using digital track & tracing, you can make you supply chains smarter and identify where your shipment is, when it will arrive and what state it is in – saving you both time and money.

A Challenging Journey for Further Growth

To summarize, the past months have not been easy, and it will not change in the near future. However, this is understandable considering the remarkable transformation that the supply chain is going through. Embracing digitalization and sustainability, ensuring visibility, and fortifying against risks are the pillars of success.

Based on the recent research, especially implementing sustainable practices might help in the process. Minimizing energy consumption, reducing waste, and optimizing transportation will eventually lead to cost savings, reduced environmental impact, and a more socially responsible supply chain. Companies that prioritize sustainable practices will benefit in the nearest future from improved brand reputation, reduced operating costs, and a competitive edge in today's environmentally conscious market.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials