Engineered Packaging Solutions and Last Mile Optimization for the Healthcare Supply Chain

Optimize Your Supply Chain with Sustainable, Regulatory-Compliant Solutions

Optimize Your Supply Chain with Sustainable, Regulatory-Compliant Solutions

With years of experience in healthcare, combined with our engineering expertise, commitment to sustainability, and focus on logistics services, we are the go-to choice for dedicated packaging solutions. We prioritize the reliable delivery of top-notch healthcare equipment.

Our global quality system, including FDA compliance, meets industry needs for protection and peace of mind from manufacturer to end user.

We are committed to reducing the environmental impact of our packaging solutions through innovative, sustainable materials and processes that exceed industry standards.

Nefab ensures that every packaging solution is designed not only for optimal protection and compliance but also for cost-efficiency, reducing total cost of ownership for our clients.

Through ISO certification, fully ISTA certified labs, and a Global Quality System, Nefab ensures that every packaging solution is in line with specific requirements and global regulations.

With decades of experience, Nefab stands as a knowledge leader in the packaging industry, offering insights and solutions that are both cutting-edge and deeply informed by a commitment to regulatory compliance and operational excellence.

The healthcare equipment supply chain encounters unique hurdles, from regulatory compliance and product complexity to last-mile delivery intricacies. Our in-depth knowledge of these challenges—coupled with innovative practices in cold chain management, global supply disruptions, and inventory optimization—allows us to craft packaging solutions that address your pain points head-on.

Healthcare equipment industry must adapt to changing regulations, including quality standards. Packaging must protect equipment during transit and meet diverse regulations.

Ensuring ‘first-time’ right success by providing detailed packing instructions, load plans, and connectivity to guarantee timely delivery of all parts without damages or missing items.

We address demands in this sector to use eco-friendly materials and processes while ensuring safety and efficacy.

Managing logistics, materials, and compliance costs requires efficient packaging solutions that are protective, compliant, lightweight, and easy to transport.

Innovative packaging solutions are custom-crafted to fit diagnostic, treatment, and life support equipment. This specialized packaging isn't just about protection; it's about ensuring smooth functionality for vital medical gear, providing utmost reliability in critical situations.

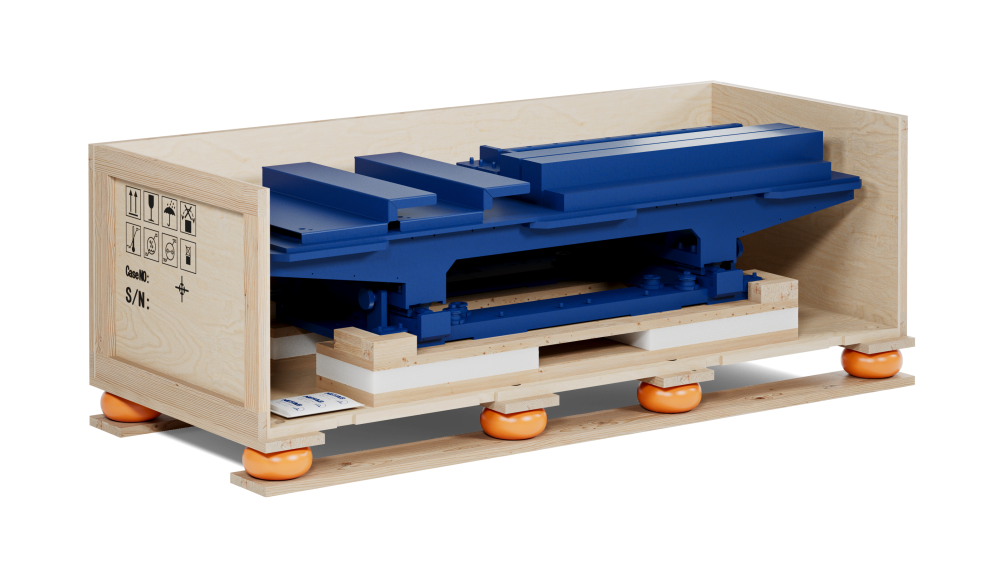

Our multi-material packaging solutions keep high-tech surgical robots, delicate diagnostic tools, and heavy products such as magnets for MRI and life support systems secure and functional.

Returnable connected packaging solutions enable environmental benefits and cost reductions from four cycles per year. By using connectivity, Nefab can predict delivery issues and track the equipment in real-time anywhere in the world.

We offer last mile optimization program, connectivity, kitting and warehousing services, and installation management planning for a seamless end-to-end service in healthcare equipment.

Cleanroom bags and PE sheets, pallets, steel assembly, and flight cases.

Tailored services for each segment of the healthcare equipment field ensure optimal delivery and functionality.

Nefab is more than just a packaging provider - we also offer:

We assist leading Healthcare customers worldwide through global coordination and dedicated knowledge teams.

We offer expertise in navigating complex global quality standards (ISO certification, ISTA certified test labs), ensuring compliance with stringent FDA regulations.

Through the implementation of our comprehensive "Reduce / Reuse / Recycle" guidelines, we contribute positively to environmental conservation efforts.

Proven to generate sustainable savings opportunities across your supply chain, towards Packaging Optimization Program and Sustainability Assessments.

Lise-Anais Swiegot

Global Segment Director Healthcare Equipment

Align your supply chain operations with the industry's rigor and sustainability goals. Connect with us to discover how our robust, eco-efficient packaging and end-to-end logistic services can elevate your company's performance.

Get In Touch with our team of specialists to strategize the ideal packaging solution for your healthcare equipment needs.

Join us on a journey of saving resources and learn about the latest trends, solutions, and best practices in sustainable supply chain management and discover smarter ways to reduce environmental impact and boost cost efficiency.