- News & Insights

- 2024

- Healthcare supply chains evolution: answering today challenges for a better tomorrow

- Sustainability

- Healthcare Equipment

- Industries

News & Insights

Healthcare supply chains evolution

Answering today challenges for a better tomorrow

According to the UN, global health issues are considered significant threats on a global scale.

A rapid rise in the aging population, growing population in developing countries and the lessons learned during COVID-19 pandemic are pushing the demand for ongoing investments in health care services. That is why the global medical devices market size is expected to grow from 536.12 billion USD in 2023 to 799.67 billion USD by 2030.

These changes will affect everyone, however, healthcare equipment manufacturers are among the ones who are most affected. They need to build sustainable supply chains and logistics operations to prepare for the challenges of today and tomorrow, while keeping the costs at bay. Read on to learn what are the key threats and opportunities for this booming industry according to our expert, Lise-Anais Swiegot, the Global Healthcare Segment Director at Nefab.

TRACEABILITY FOR IMPROVED VISIBILITY & DEVICE INTEGRATION

It is critical for healthcare equipment manufacturers to plan in advance for sudden shortages, manufacturing downturns and delays in deliveries. This is especially important for life-saving equipment which needs to be delivered on time to ensure medical staff can provide necessary medical care to its patients.3 The rising industry trend is switching to connected packaging and logistics solutions, which help you track the equipment in real-time anywhere in the world. This technology allows you to predict delivery issues and monitors the products’ conditions. “Based on our calculations, using connected flows can both help reduce costs and increase healthcare supply chain efficiency as well as responsiveness by up to 40% lead time”, explained Lise-Anais.

Delivering healthcare equipment to end-users, such as hospitals and clinics, often involves navigating complex logistics networks and requires the “first-time-right” approach. As a result, by utilizing detailed packing instructions, load plans, site plans, and a connectivity service for reporting shortages, you can ensure that all parts are accounted for an arrive on site undamaged. Additionally, this way the challenge of non-standardization in medical device communication protocols is addressed, which otherwise may complicate the connection of devices from various vendors.

Using connected flows can help reduce costs and increase healthcare supply chain efficiency by up to 40% lead time.

GLOBAL QUALITY FOR IMPROVED SAFETY & EFFICIENCY

Healthcare equipments are highly sensitive, high value, and highly complex products. Therefore, they require designed packaging solutions with high focus on quality and cost pressure while minimizing waste and environmental impact. Providing these solutions to end-users, like hospitals and clinics, typically requires overcoming many challenges on the supply chain side, which in turn impact the final quality and design of the packaging.

Using a trusted supplier that offers the same level of service globally, ensures that both the packaging and the delivery will be taken care of with the same diligence and care anywhere in the world. This is especially important for transporting a wide range of medical devices, from very small diagnostic tools to heavy-duty Magnetic Resonance Imaging machines. Luckily, there are global quality systems and standards that can be followed to ensure consistency across the globe. “Through ISO certification and fully ISTA certified labs, you can validate healthcare packaging solutions in line with specific requirements and global regulations”, explained Lise-Anais.

By following ISTA testing standards and industry requirements, healthcare equipment manufacturers ensure their packaging solution complies with all relevant standards and regulations.

SUSTAINABILITY & INNOVATION IN BOTH PACKAGING & SERVICES

Designing innovative yet sustainable packaging solutions for healthcare equipment is difficult due to many regulations and long approval processes.4 However, there are many attractive packaging alternatives that reduce costs and material waste. From easily recycled and low-weight fiber-based packaging solutions to highly protective and resistant constructions from straw that can stack over 4 tons of product weight, there are many ways for healthcare industry to reduce cost and green footprint. “We have seen companies reducing their CO2-eq emissions significantly simply by switching to alternative packaging materials”, commented Lise-Anais.

Keeping in mind the changing structure of the logistic flows, returnable packaging systems are also growing in popularity within healthcare equipment industry. In case of closed loops, between a limited number of distribution points, it makes financial sense to replace one-way packaging with a returnable alternative. Once arrived at the final destination, these boxes are unpacked, loaded with i.e. broken or unused parts and sent back, increasing the loop efficiency. When they travel empty, they can be stacked flat on each other thanks to collapsible structure. Besides obvious environmental benefits, returnable packaging reduce transportation costs as well as provide full visibility throughout the supply chain flows. “If the packaging completes at least four cycles per year, the investment into returnable system already pays off”, explained Lise-Anais.

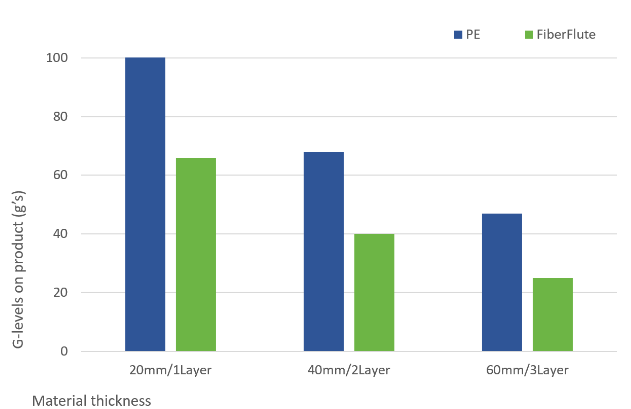

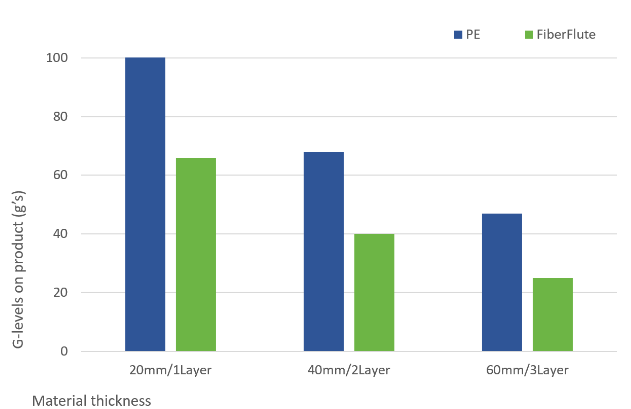

The comparative analysis between polyethylene foam (30kg/m3) and fibre-based cushioning solutions proved that the fibre-based alternative offers same protection while using less material and being more environmentally-friendly.

ONE-STOP-SHOP FOR PACKAGING & LOGISTICS SERVICES

Without doubt the medical device manufacturers are standing at the crossroads of supply chain evolution. However, partnering with the right packaging and logistics provider can help save them costs, time, and resources, while optimizing logistics process and providing visibility into the supply chain. This is especially important for global healthcare industry players that require the same level of service across all geographies under one point of contact.

“Healthcare manufacturing industry is currently running at a full steam. The complexity and importance of safely transporting the healthcare equipment are crucial to saving lives, which is why manufacturers demand reliable and quality-driven sustainable packaging solutions and logistics services. The evolution into more agile, digital and circular supply chains presents a challenge, but it can be accomplished if all stakeholders collaborate “, summarized Lise-Anais.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials