Innovation & Sustainable materials

Sustainable packaging materials and sourcing is the foundation of circular solutions. At Nefab we take a global and local approach to strategic sourcing, and we are continuously scanning the market for new, innovative materials. In addition, we continue to invest in R&D and in partnership with like-minded companies to build circular, resource efficient business models.

Waste management

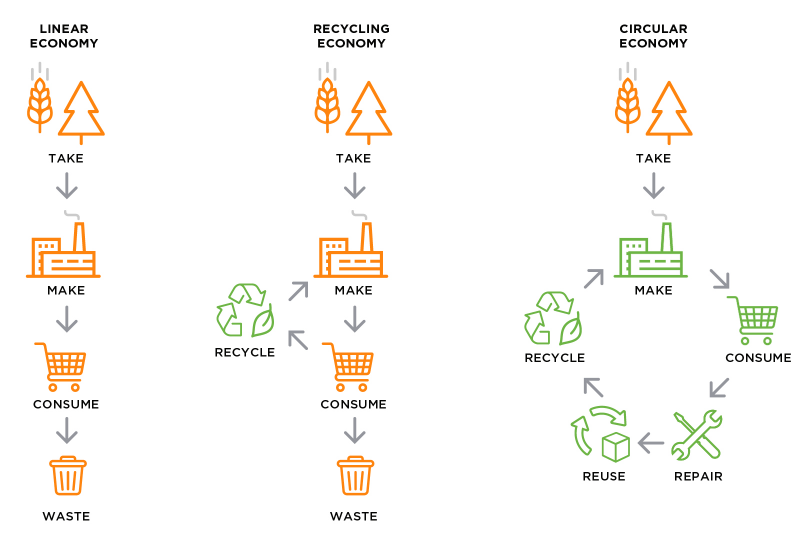

Waste, as well as resources, should be well managed. Within Nefab, waste is carefully sorted into the following waste streams; wood, metal, corrugated and paper, plastics and foam, general mixed waste. We strive to optimize end of life scenarios by developing partnership to maximize recyclability, reusability, and circularity. Our ambition is to turn waste into new resources.