We save resources in supply chains

On average, Nefab's solutions reduce total costs by 20% and carbon footprint by 31%

On average, Nefab's solutions reduce total costs by 20% and carbon footprint by 31%

Nefab is a global provider of industrial packaging, logistics and digital services.

Smart packaging solutions that are engineered, prototyped, and tested

End-to-end-optimization - experience the synergies of bundling logistics and packaging.

Our tracking solutions enable companies to achieve transparency and accountability in global supply chains.

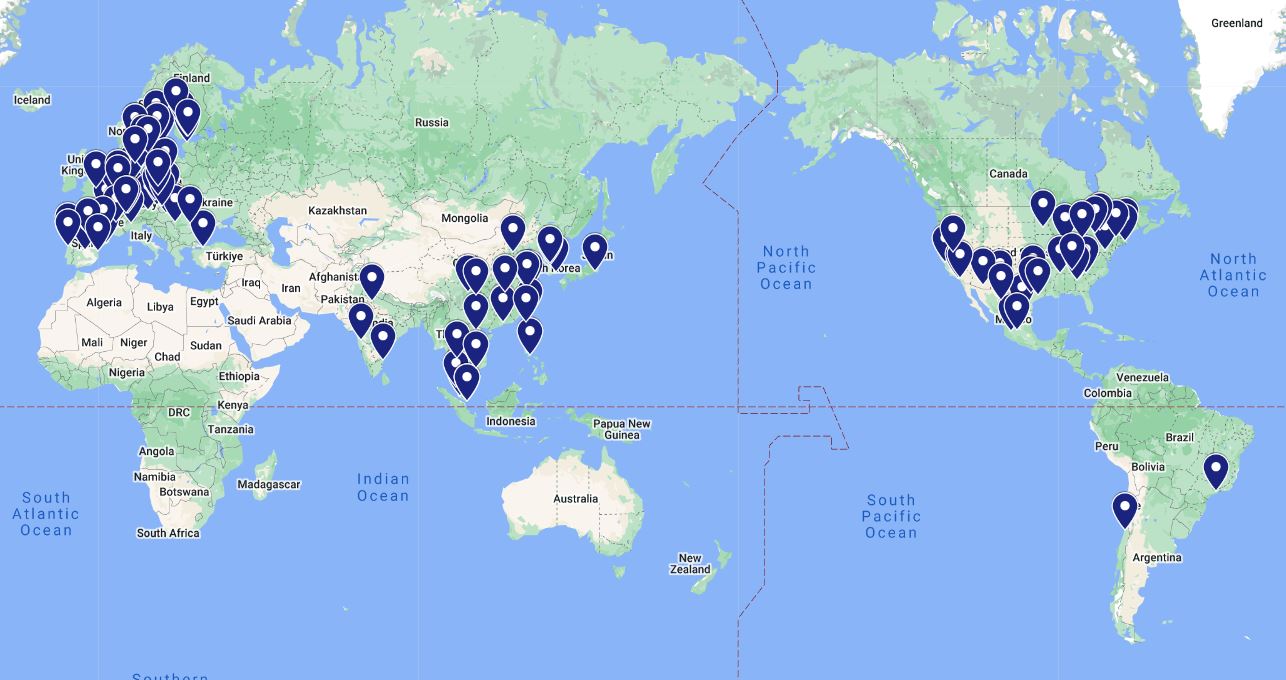

Our global supply & service platform consists of around 100 production and service units.

GreenCalc is a trusted Life Cycle Analysis (LCA) software that quantifies financial and environmental savings in supply chains.

With more than 75 years of experience combined with competence and presence in more than 38 countries, we offer global solutions and local service worldwide to companies in industries such as Telecom, Datacom, Semicon, Energy, Healthcare equipment, Mining & Construction, and LiB & E-mobility.

Nefab saves environmental and financial resources by optimizing supply chains. We do thus by innovating together with our customers to create smarter packaging and logistics solutions while always respecting people and ethical standards.

Million USD in sales

Countries

Locations

Employees

The Nefab Total Cost Approach aims to optimize your packaging, reducing the overall cost and enviromental impact. We determine the best type of packaging material, size and internal packaging that provides the best protection while lowering your overall cost.

We save environmental and financial resources by optimizing supply chains. Explore how GreenCalc can help you to reduce your environmental footprint.

We design, prototype, test, and deliver complete packaging solutions and services aimed at reducing our customer's total cost for logistics and product protection, as well as reducing the environmental impact in their supply chains.

Experience the synergies of bundling logistics and packaging. We offer third-party logistics services to global companies within the industry segment who need customized solutions and end-to-end-optimization.

Transparency and accountability are key to an efficient global supply chain and the effective resolution of disruptions. Our portfolio of tracking platforms enables companies to achieve this transparency across multiple business application areas.

We have the capability to develop packaging in a variety of materials and leverage that to design complete packaging solutions that are stronger due to this combination of materials.

Our engineers work closely with our customers to develop a suitable packaging solution for their specific product. With our in-house testing capabilities, we are also able to test and validate the design to ensure that the packaging protects the content for the entire journey.

Fiber based solutions is available all over the world. It can be customized to engineer mono-material solutions that are easily recycled in the paper stream or used in combination with other materials.

Our plywood solutions are strong, nail-free for a safer, and offer a great printing area, giving customers a chance to make their brand stand out. Plywood is compliant from an IPPC perspective due to its thin veneers and therefore works great for export shipments.

Wood is used for outer packaging solutions, pallets and heavy skids. Using those as a baseline, it is possible to design a wide variety of packaging. All our wood-based solutions are ISPM 15 compliant and can be used as export packaging.

From standard foldable large containers (FLCs) to customized solutions made of multiwall plastic sheets, and injection-molded or vacuum-formed trays.

Join us on a journey of saving resources and learn about the latest trends, solutions, and best practices in sustainable supply chain management and discover smarter ways to reduce environmental impact and boost cost efficiency.