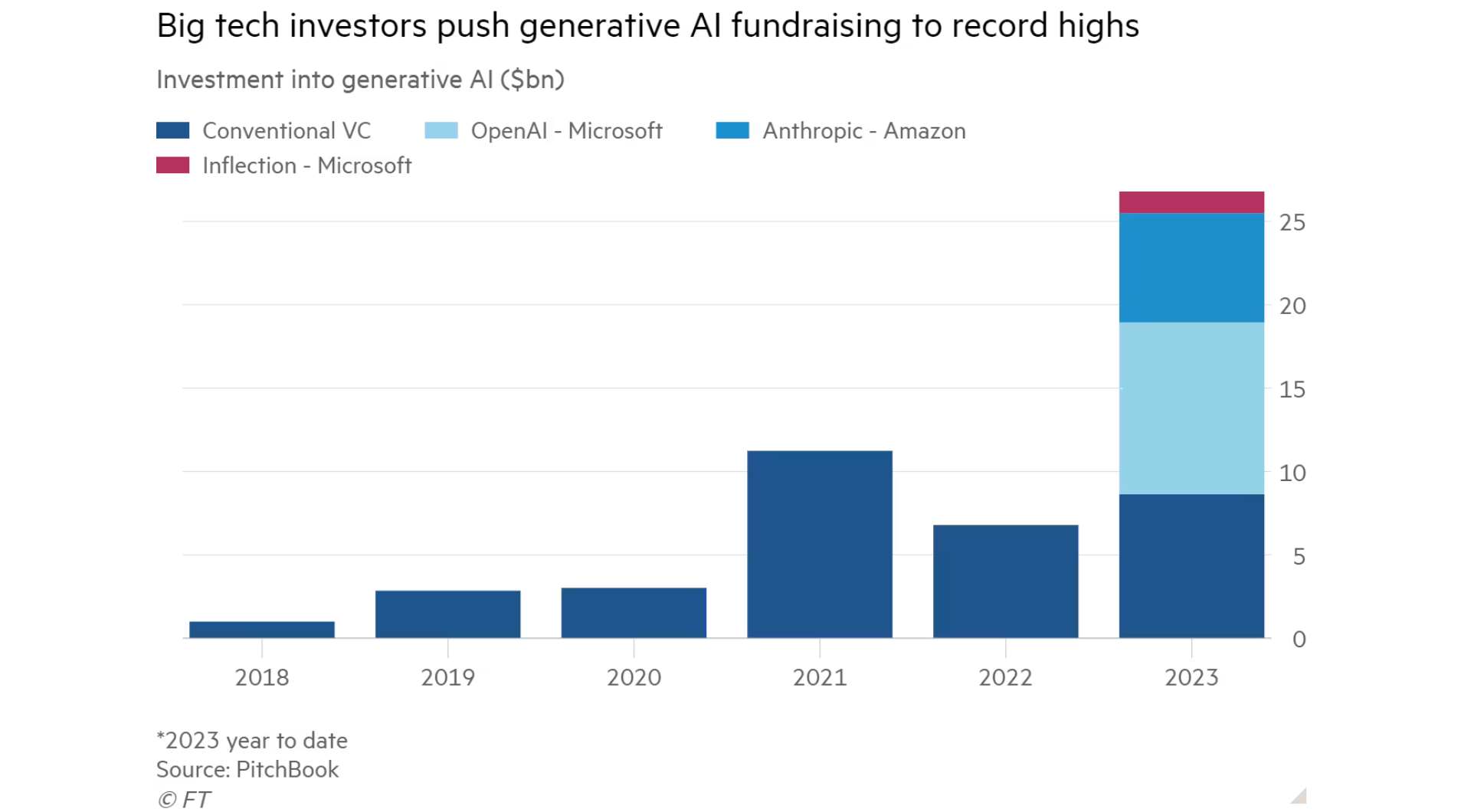

The AI revolution is in full swing. No wonder major data-driven corporations are allocating record-breaking funds to new technology development, aiming to keep pace with the exponential growth of generative AI. These cost pressures force many companies to scrutinize spending to drive further growth. The increasing trend of prioritizing efficiency frees up companies' resources, redirecting them toward fostering innovation. Optimizing resources and allocating them effectively has never been more critical.

Many executives nurturing innovation are driven by a sense of urgency. In rapidly evolving industries, businesses compete based on their ability to sense and respond to change more quickly than others1. The latest research confirms that although approximately 120-130 new hyperscale data centers will be added yearly, the primary driver of capacity growth will be the larger scale of these newly established centers, attributed significantly to advancing generative AI technology2. However, optimizing resources, creating operational efficiency, and ensuring the company is ready to absorb more innovation is not a simple task. Supply chain managers are under increasing pressure to provide resilient, cost-effective, and secure transportation of data center equipment to extend companies’ capacity to innovate. With the current economic uncertainty, they are grappling with how to speed up the process, maintain a competitive edge, and ensure product protection without breaking the bank.

The Big Tech companies are investing in data centers and servers to compete in the race for advanced generative AI technology. Source: Financial Times

Optimized packaging boosts the bottom line

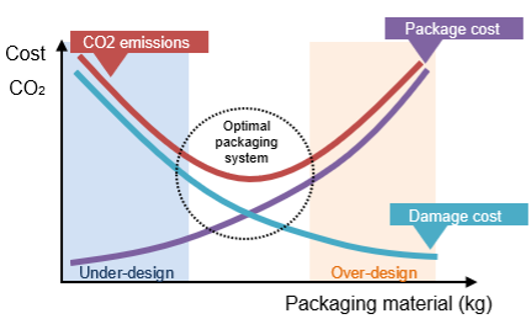

Value engineering promotes substituting materials and methods with cost-effective alternatives without sacrificing functionality3. This approach integrates engineering principles into packaging design, ensuring optimal solutions. Optimized packaging not only protects products during transportation, storage, and handling but also enhances usability and disposal. Using inadequate packaging material increases the risk of damage and complicates handling. Simply adding material doesn't improve packaging; it often wastes resources, adds cargo weight, and subsequently increases transportation costs. Optimizing packaging minimizes costs, weight, and space while ensuring sufficient product protection.

The good news is that saving costs and optimizing transportation can go hand-in-hand with reducing waste and CO2-eq emissions. A thorough Life Cycle Analysis process helps compare the price and environmental impact of the existing packaging with the new optimized solution. A good example is GreenCalc, a tool that identifies areas of improvement in currently used solutions by quantifying an extensive range of climate-affecting metrics. As a result, it provides detailed and data-driven recommendations regarding total cost and environmental impact.

Optimizing packaging solutions cuts costs, maintains product safety, and minimizes environmental footprint.

Packaging testing ensures product protection

In today's fast-paced market, speed is crucial. This holds particularly true for companies that want to stay at the forefront of innovation. Building the capacity to prepare for growth is a priority for many executives in data-driven industries such as cloud, banking, or telecom. Many of their executives are heavily investing in new data centers filled with state-of-the-art IT equipment, which is expensive and very sensitive. Ensuring appropriate cushioning and designing optimized packaging that provides the required protection is paramount.

Partnering with ISTA-certified labs can be immensely valuable. Subjecting packaging to rigorous testing procedures such as drop testing, vibration testing, and compression testing helps identify potential vulnerabilities, allowing for necessary improvements. Moreover, testing helps ensure that the packaging solution complies with all relevant standards and regulations and does not negatively interact with the transported equipment. As a result, testing reduces costs associated with product damages, delayed delivery, or replacements, ultimately enhancing the bottom line.

With a powerful hub of more than 250 engineers and 6 ISTA-certified labs, Nefab can support companies worldwide.

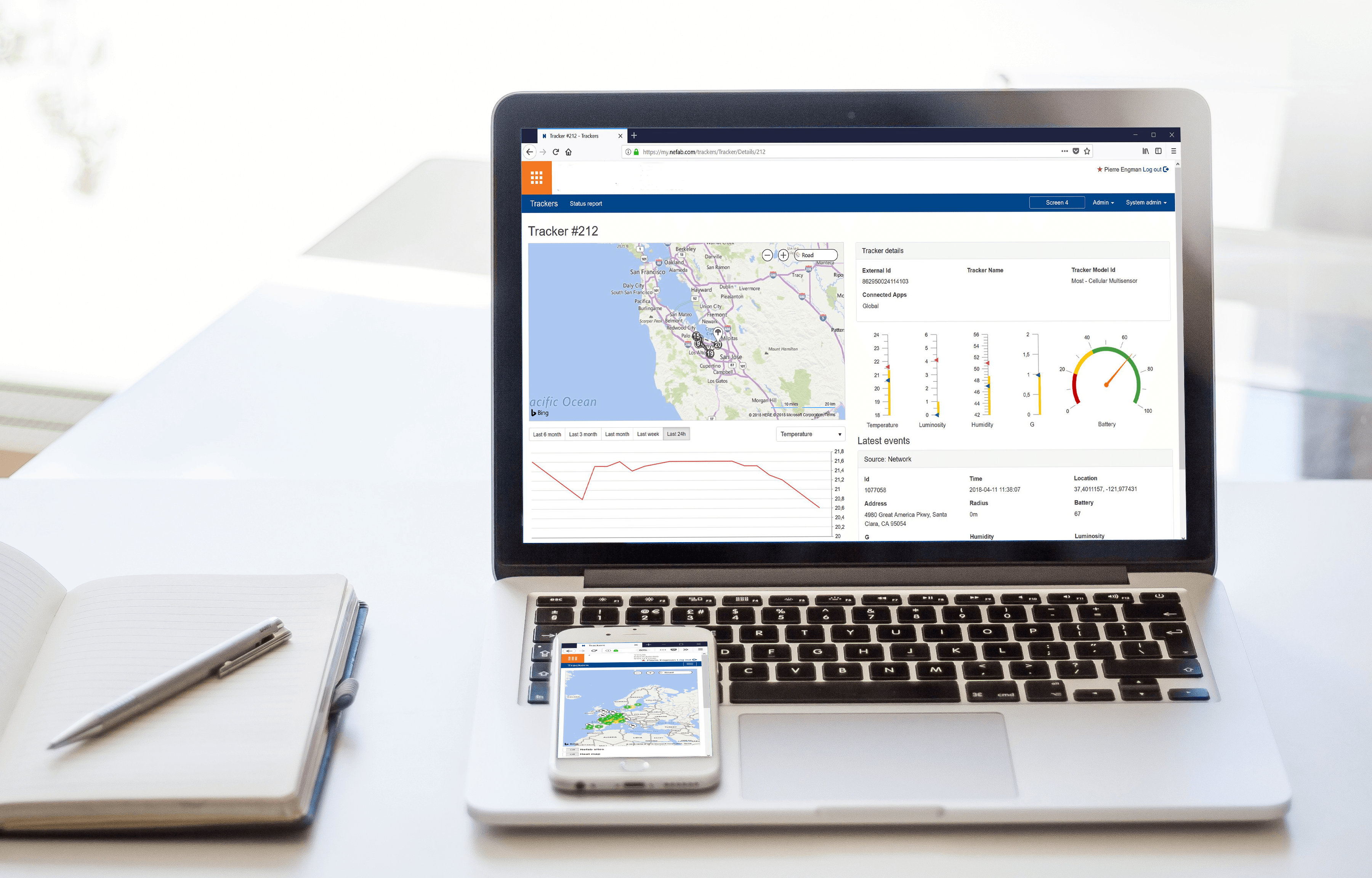

Supply chain transparency increases operational efficiency

Increasing supply chain transparency and optimizing inventory and asset management helps mitigate escalating costs and maximize efficiency. In modern connected packaging solutions with advanced tracking capabilities, every asset has a sensor associated with a relevant data point. This data is then aggregated and reported in real time. Businesses can receive alerts when certain events occur, including shock, packaging tampering, or late deliveries. Moreover, the sensors measure the temperature and humidity of the environment surrounding a product. The data can also be used to assess routes, delivery performance, handling, utilization, and lead times. Equipped with the information, companies can improve processes, increase efficiency, and lower the costs of their logistical flows.

Technology is developing at an unprecedented pace, and ensuring compatibility between different systems can be challenging. This is why Nefab created a system that allows full interoperability across various systems. Currently, the network cooperates with over 70 different plug-and-play devices across different technologies and monitors over 80 million events daily from over 100 countries around the globe. This means that new, cheaper devices, regardless of their underlying technology (QR, RFID, connected gateways, GPS, Bluetooth, etc.), can be added to the existing device fleet without replacing the current equipment and infrastructure. Nefab estimates that hybrid technology solutions help to save up to 95% in overall device costs.

Connected packaging enhances decision-making, accelerates processes, and improves inventory management, resulting in cost savings.

Start saving resources today

Sustainability, value engineering, and innovation are the building blocks driving operational efficiency programs. At Nefab, a global leader with local reach, we harness our packaging engineering prowess to craft innovative, customized packaging solutions. Leveraging our network of ISTA-certified labs ensures top-notch quality and reliability. With sustainability ingrained in our company's DNA, every solution we create is inherently environmentally friendly. Get in touch to see how we can help you optimize your packaging and save resources in the supply chain.