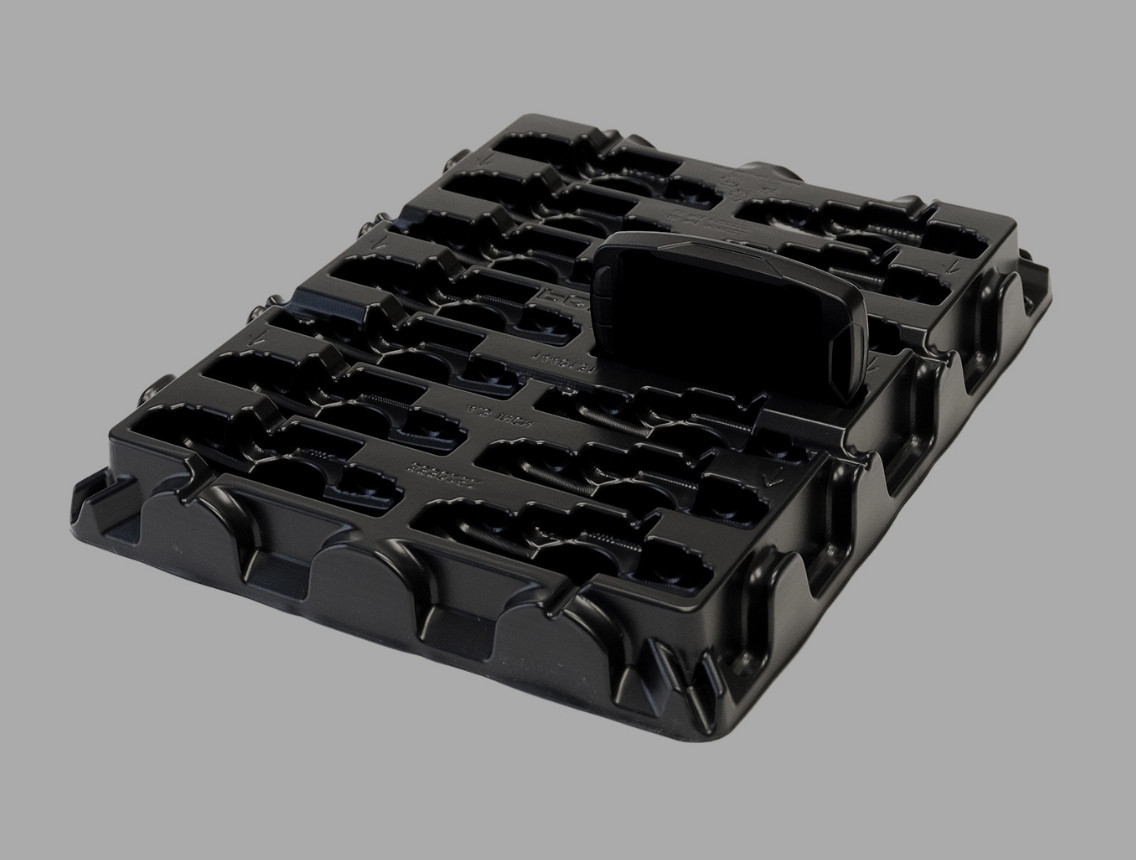

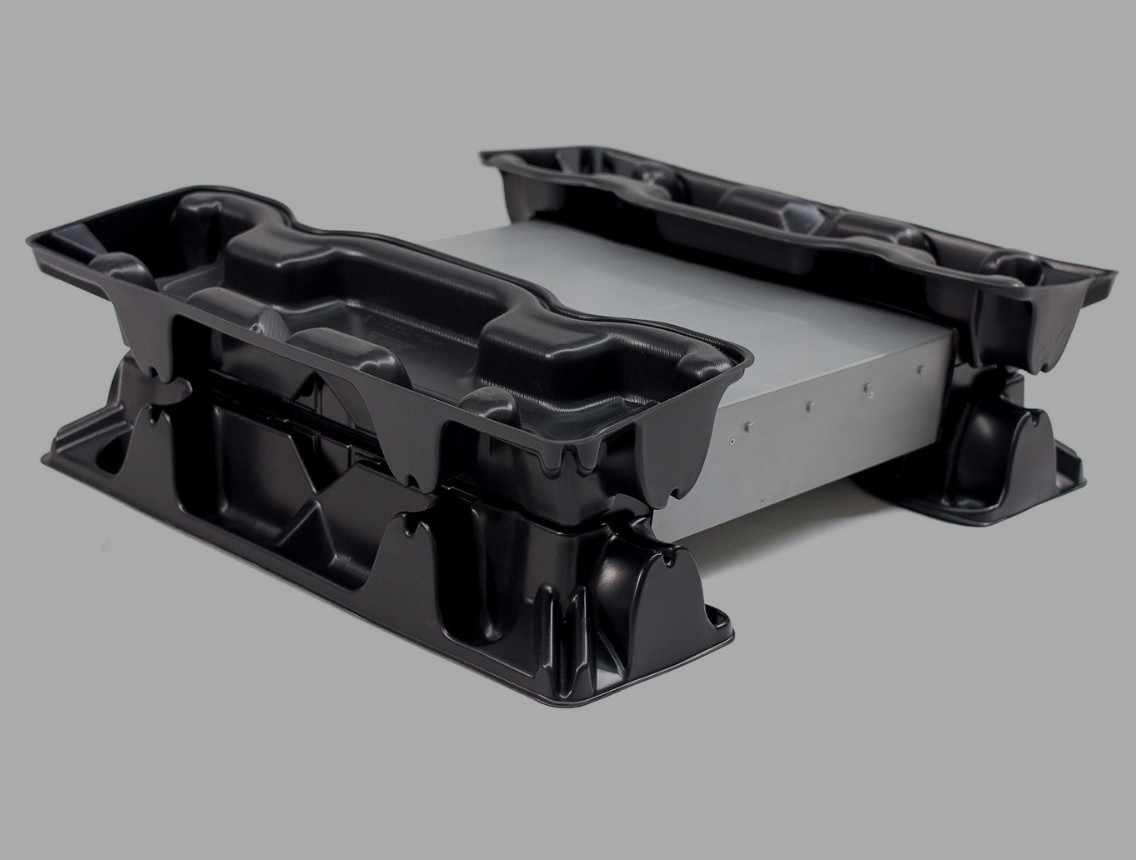

Thermoformed solutions are a result of a process called thermoforming or vacuum forming. This is the manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product.

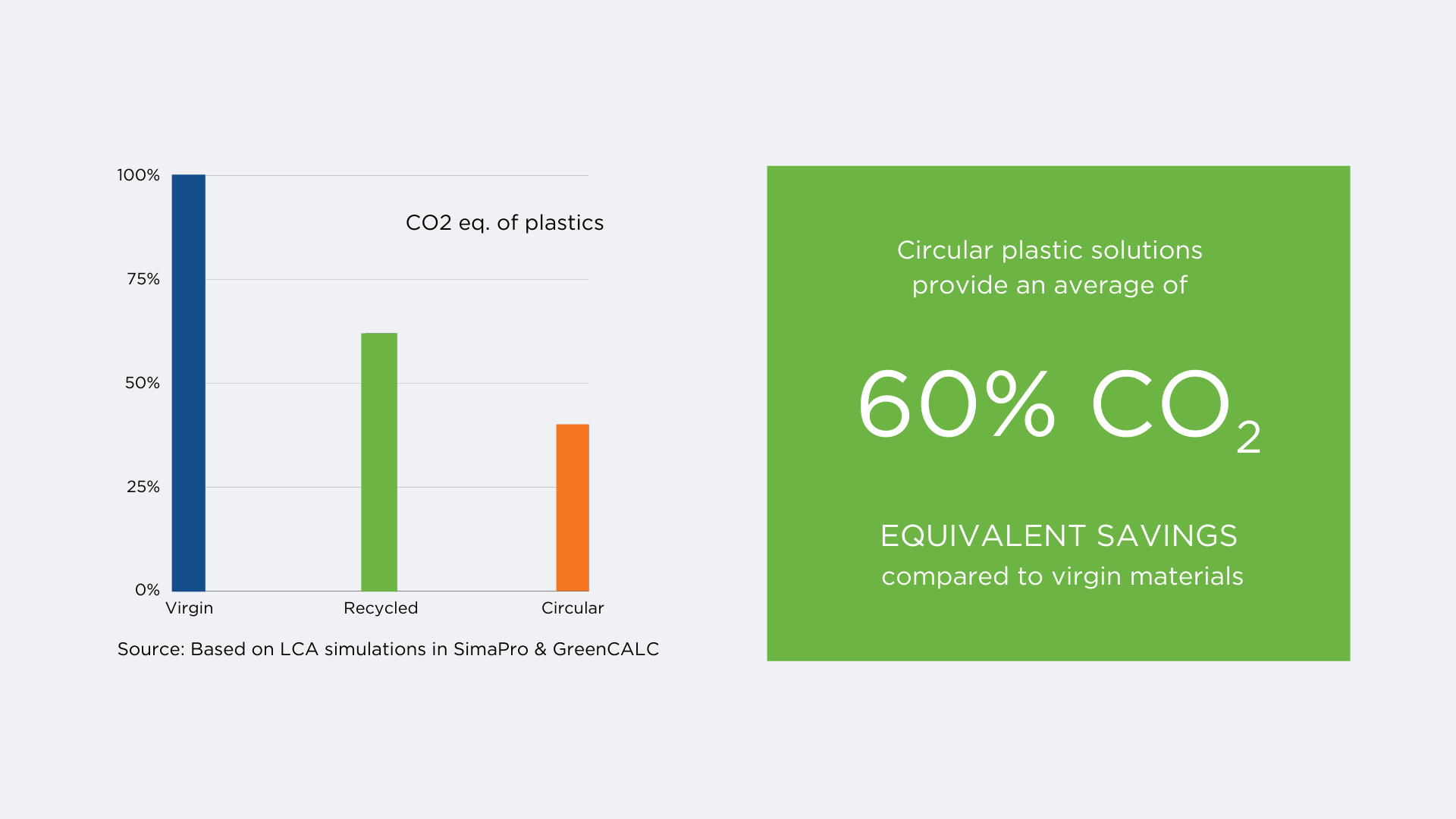

This molding quality is also the reason why thermoformed solutions are considered sustainable plastic products. They can be molded in different shapes and sizes, collected, cleaned, and remolded again. Besides, thermoformed applications are usually light and nestable, which means less material is required to pack, store, and transport products.

Because they can be reduced, reused, and recycled thermoformed solutions are perfectly fit for return and circular flows.