Nefab's newly launched thermoformed solutions are made of high recycled content and are available globally for several industries, including the Automotive, Electronic, Telecom, Aerospace, and Lithium-ion Battery segments.

- Between 2020 and 2021, Nefab made important acquisitions - Szkaliczki and Partners Plastic Processing Ltd (Szkaliczki) and Reflex Packaging (Reflex). While Skaliczki secures Nefab’s leading position in technology and engineering capabilities for thermoformed trays, Reflex secures Nefab’s global leadership in sustainable cushioning solutions.

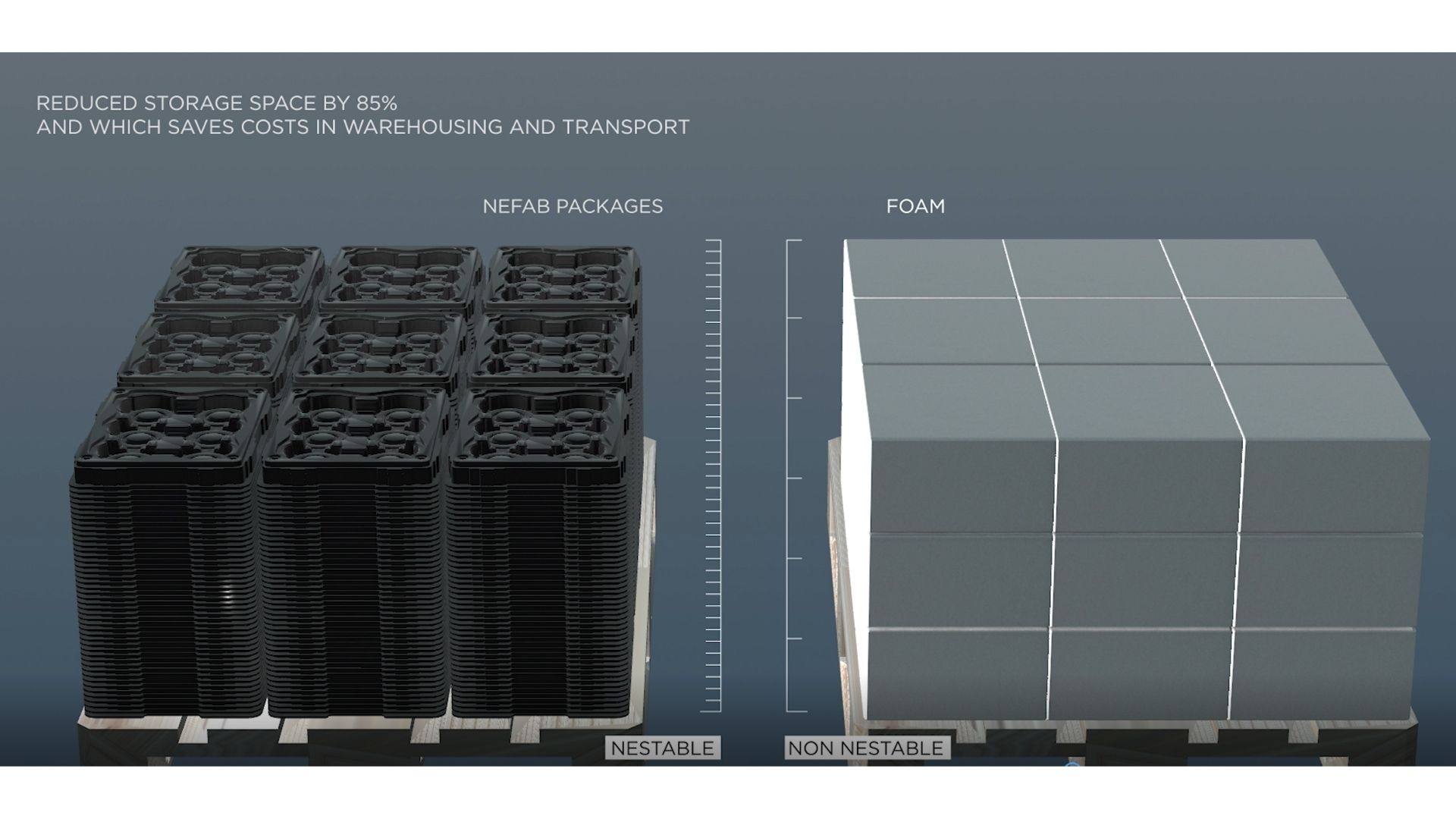

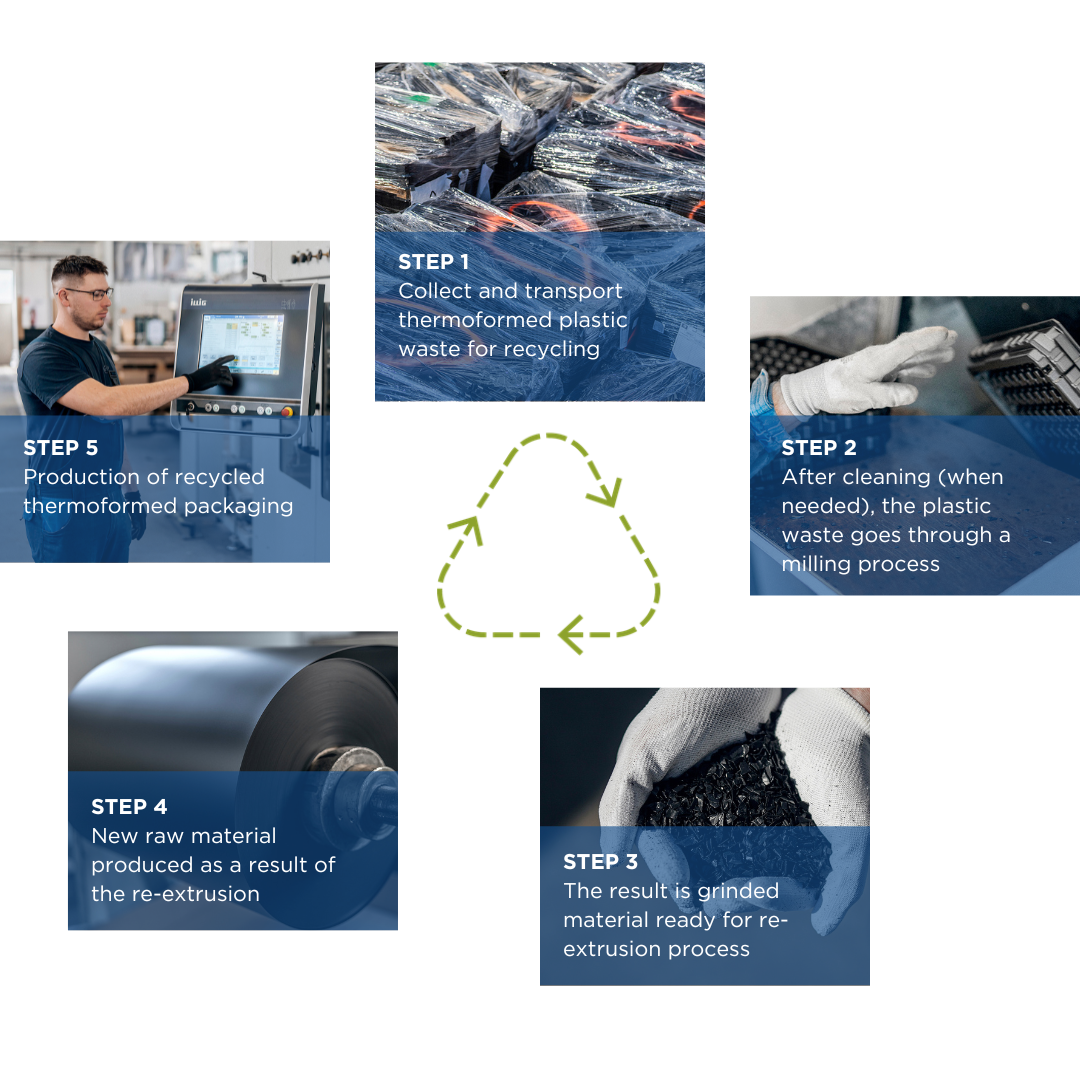

- Nefab’s thermoformed solutions, include sustainable plastic packaging trays and cushioning applications. Both are made primarily from recycled plastics and 100% recyclable materials. They are also efficiently applicable to one-way flows, as well as return flows and circular flows.

- Ideal for automated lines that require precision packaging due to robotic handling, Nefab’s thermoformed solutions are engineered to be highly protective and to match specific product requirements and regulations.

![<p> </p>

<center>

<p style="font-size: 20px;"><strong>We save resources in supply chains, for a better tomorrow. </strong></p>

</center>

<h3 aria-level="1"> </h3>

<center></center>

<h3 aria-level="1">Want to learn more? </h3>

<h4><strong><span data-contrast="none">GET IN TOUCH</span></strong><span data-ccp-props="{"201341983":0,"335559737":851,"335559738":120,"335559740":276,"469777462":[5580,9000],"469777927":[0,0],"469777928":[1,4]}"> </span></h4>

<p><a href="/link/3608e3f434584046873b7bce413fc180.aspx"><span data-contrast="none">Contact us</span></a><span data-contrast="auto"> to learn more about our circular plastics solutions.</span><span data-ccp-props="{"134233117":true,"134233118":true,"201341983":0,"335559737":0,"335559740":240,"469777462":[5580,9000,5580,9000],"469777927":[0,0,0,0],"469777928":[0,0,1,4]}"> </span></p>

<h4><strong><span data-contrast="none">LEARN MORE</span></strong><span data-ccp-props="{"201341983":0,"335559737":851,"335559738":120,"335559740":276,"469777462":[5580,9000],"469777927":[0,0],"469777928":[1,4]}"> </span></h4>

<p><a href="/link/224bb448112348ceaf620946e193c64b.aspx"><span data-contrast="none">GreenCALC</span> <br /></a><span data-contrast="none">Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions</span><span data-ccp-props="{"134233117":true,"134233118":true,"201341983":0,"335559737":0,"335559740":276,"469777462":[5580,9000,5580,9000],"469777927":[0,0,0,0],"469777928":[0,0,1,4]}"> </span></p>

<p><a href="/link/4990b3417df14701a76611e3efc0455b.aspx"><span data-contrast="none">Sustainable Solutions</span> <br /></a><span data-contrast="none">Engineered packaging for sustainable supply chains</span><span data-ccp-props="{"134233117":true,"134233118":true,"201341983":0,"335559737":0,"335559740":276,"469777462":[5580,9000,5580,9000],"469777927":[0,0,0,0],"469777928":[0,0,1,4]}"> </span></p>

<p><a href="/link/5db4d10c5fa048039bb6871144a2f98f.aspx"><span data-contrast="none">Sustainable Materials</span> <br /></a><span data-contrast="none">Fiber-based packaging and raw materials</span><span data-ccp-props="{"134233117":true,"134233118":true,"201341983":0,"335559737":0,"335559740":276,"469777462":[5580,9000,5580,9000],"469777927":[0,0,0,0],"469777928":[0,0,1,4]}"> </span></p>](/globalassets/nefab.com--group-site/thermoform/cushioning/blogcovers_sustainabilityinsupplyindustrialpackaging-1.png)