Inner Packaging

- Solutions

- Packaging Solutions

- Inner Packaging

Inner Packaging Solutions to protect your products

Inner packaging help protect the product from transport and storage damages. The inner packaging surrounds the product and can be designed to protect against many different circumstances.

Thermoformed Cushioning solutions

Nefab’s thermoformed cushioning solutions are sustainable plastic packaging applications made from high recycled content.

Read more

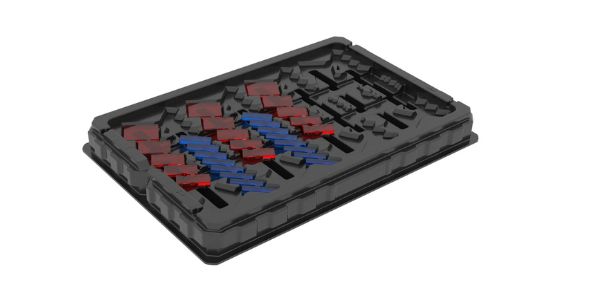

Thermoformed Trays

Thermoformed trays are optimized to your specific needs, creating a packaging that that is tailored for your products and supply chain.

Read more

Corrosion Protection

Corrosion is a reaction between metal and gases in the environment. Moisture and temperature changes are the most important factors that cause corrosion to metal and steel components. Nefab offers many preventive solutions such as: barriers, desiccants, and corrosion inhibitors.

Read more

ESD Products

Nefab has ESD experts and a complete range of shielding, conductive, insulating and dissipative products to design solutions that offer the required protection for use either inside or outside an electrostatic protected area (EPA).

Read more

Cushioning

Foam cushioning is used to protect against shock and vibration. There are numerous different options to protect the goods and the final solution will be dependent on factors such as: product fragility, product weight, shipping and handling conditions, batch size and more.

Read more

Blocking and Filling

The purpose of blocking materials is to immobilize the product and assure the right protection. The purpose of void-filling materials is to completely fill the empty spaces around the packed product.

Read more

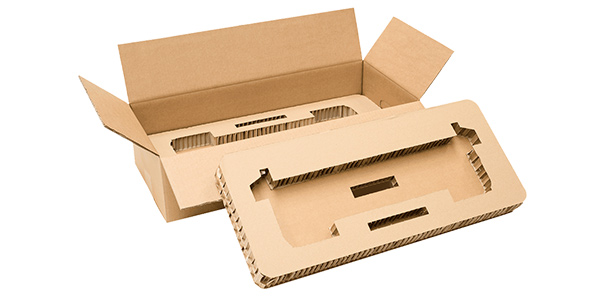

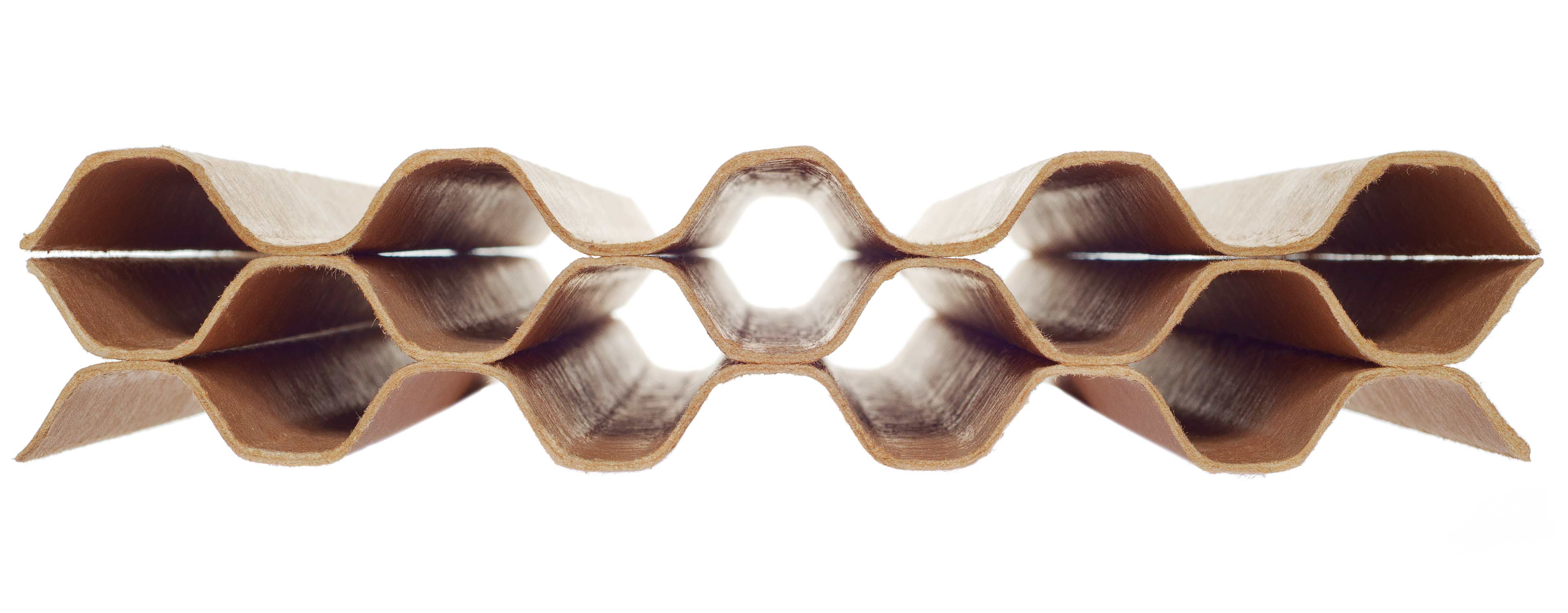

FiberFlute

FiberFlute is a sustainable packaging solution that provides outstanding cushioning performance for a wide range of products. Fiberflute is an eco-friendly alternative to foam and is 100% paper-recyclable.

Read more

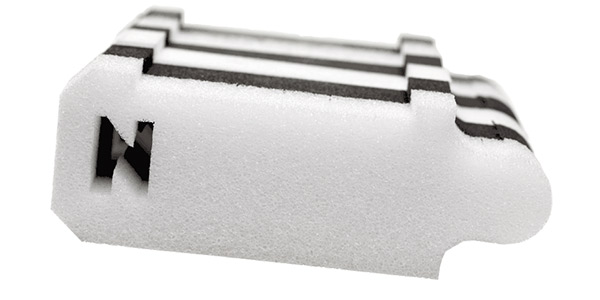

Nefab WoodFoam

WoodFoam Solutions are made from a recyclable foam and used as cushioning for lightweight products. It is a sustainable and healthy alternative to plastic-based and PU foam. The Solution is fiber-based, 100% isocyanate-free, repulpable and recyclable as paper.

Read more