Nefab’s Electric Vehicle Initiative (EVI) program background

2017 may become an important breakthrough year for the Electric Vehicle deployment worldwide, due to several key players who have already started mass production of Electric Vehicles. Executives from the automotive industry have clear priorities in their agenda’s: Connectivity and Digitalization, Hybrid Electric Vehicles (HEVs), and Battery Electric Vehicles (BEVs). Main drivers of the increasing EV deployment are CO2 emissions, falling battery costs, improve driving range, and expanding charging infrastructure. The development has considerable impact on our customers in the energy and automotive industry. One challenge is in the transportation area and handling of dangerous goods such as Lithium Ion Batteries for automotive and energy storage applications. Since the beginning of 2016, Nefab has launched a global Electric Vehicle Initiative (EVI) to entirely specialize in Lithium Ion Battery packaging solutions for large applications such as EV or energy storage Lithium Ion Batteries.

How to ensure safe transportations of Lithium Ion Batteries by air?

The Federal Aviation Administration (FAA) recorded around 160 air and airport incidents caused by batteries carried as cargo or baggage in the last 25 years. Starting April 2016, the International Air Transport Association (IATA) has forbidden the transportation of Lithium Ion Batteries as cargo on passenger aircrafts together with other provisions such as 30% State of Charge (SOC) for Lithium Ion Battery cargo on aircrafts. One of the safety issues is fire incidents that may occur due to several reasons, such as internal short circuit caused by defects inside the cell for example. Nefab understands the challenges of dangerous goods transportation and has become a knowledgeable packaging partner for key players in the growing market of Lithium Ion Batteries. Nefab has designed, manufactured and tested numerous packaging solutions for Lithium Ion Batteries and other dangerous goods such as oxygen generators, which are transported by air.

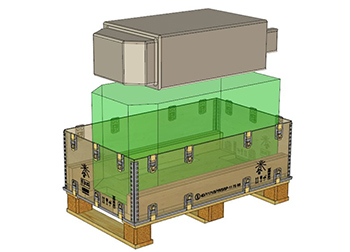

Nefab’s offer for Lithium Ion Battery packaging solutions

Contact details

Discover our expertise and range of smart packaging solutions for lithium ion batteries and contact an expert for LiB packaging.