The Challenge: Addressing Supply Chain Bottlenecks with Streamlined Packaging Solutions

Our customer's existing supply chain process for packaging relied on a fragmented approach that introduced several inefficiencies, including packaging components that were shipped separately and required a third-party vendor to assemble them into kits.

The components were manually pulled from inventory, frequently resulting in errors due to inconsistencies in picking processes. Significant transportation costs arose from shipping the unassembled packaging materials across extended distances to the third-party vendor. The approach also contributed to poor warehouse utilization and higher environmental impact.

These challenges created bottlenecks in the supply chain and increased the cost and complexity of the operation. The company recognized the need for a solution to streamline processes and eliminate unnecessary steps.

The Solution: Innovative Packaging Redesign with ExPak PS2

The proposed solution centered on redesigning our customer's existing packaging system to address the inefficiencies in its supply chain. Key actions included:

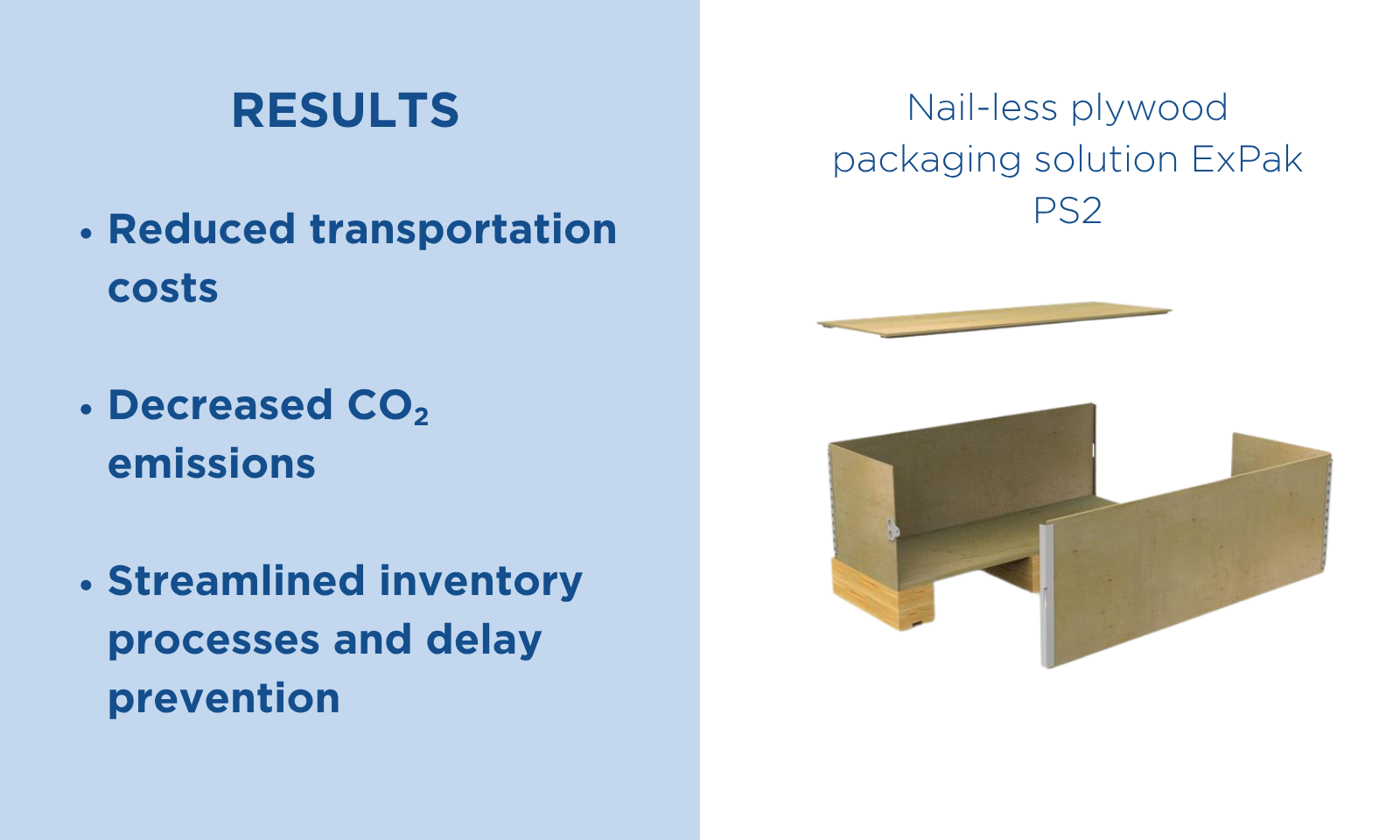

- Developing a Redesigned Packaging Solution: The new packaging system, identified as nail-less plywood packaging solution ExPak PS2, enabled components to be pre-kitted instead of requiring third-party assembly. The redesign ensured compatibility and eased the packaging process.

- Eliminating Third-Party Logistics: By enabling in-house kitting through the redesigned packaging, the company removed the need to transport materials to an external partner for assembly. This change significantly reduced transportation costs and eliminated the associated CO2 emissions.

- Maximizing Warehouse Space Efficiency: The updated packaging design allowed for compact stacking and designated storage space, ensuring optimized warehouse utilization.

- Improving Operational Processes: The simplified solution minimized inventory pulling errors and improved material handling, allowing the company to operate with greater efficiency and accuracy.

Through open discussions with our customer, our redesign efforts aligned with their operational goals while adhering to the relaxed packaging requirements introduced during this period.