These are essential for transporting sensitive components like lithium-ion batteries (LIB) safely and in compliance with strict regulations (e.g. UN dangerous good regulation). But many of these legacy packaging systems are single-use, hard to recycle, or made from composite materials that end up in landfills.

A recent report from the Suppliers Partnership for the Environment (SP)1 highlighted this issue, noting that the legacy plastic packaging at OEMs and supplier facilities frequently lacks recycling pathways, making it difficult for manufacturers to meet their sustainability goals.

The problem isn’t just about materials. As the Ellen MacArthur Foundation notes, most products and systems are created in ways that make waste inevitable2. Packaging often is no exception.

Fortunately, this is starting to change, as the new trends in packaging design aim to make it part of the solution rather than the problem.

Packaging Designed for Circularity

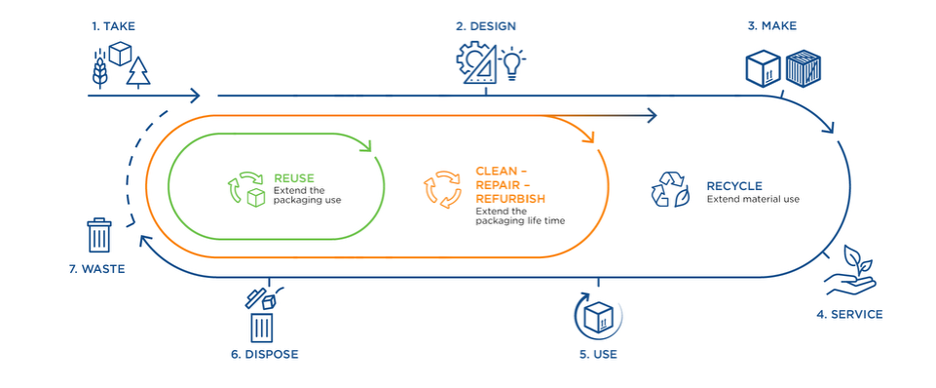

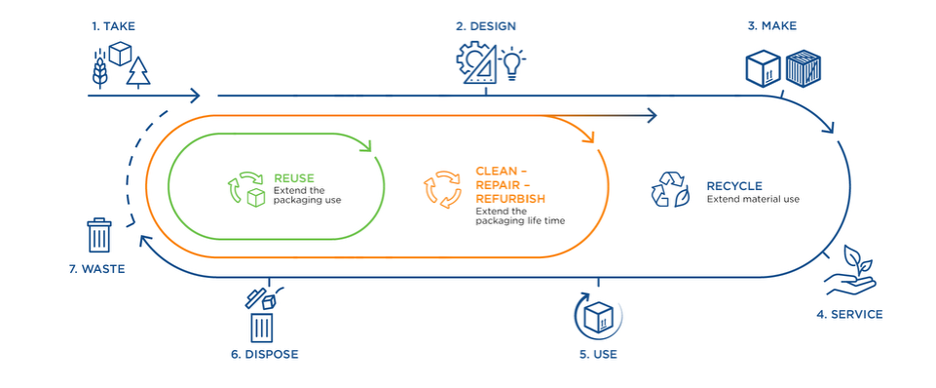

The move toward a circular economy starts with smart design. Rather than focusing on waste management, the industry is turning to waste prevention in line with the “designed to recycle” principles. This concept, also known as “Designed for Circularity”, involves developing packaging that can be reused, repaired or efficiently recycled at the end of its life.

Key principles of the circular packaging design include:

• Prioritize reuse: packaging should be designed to be durable, modular, and easy to repair or repurpose.

• Recycle only as a last resort: the goal is to maintain material value through multiple lifecycles.

• Design for disassembly: materials should be easy to separate and process.

• Standardize materials: the design focuses on the use of recyclable plastics and avoid composites unless easily separable.

The “Designed for Circularity” concept involves creating packaging that can be reused, repaired or efficiently recycled at the end of its life. Source: Nefab

Practical Steps Toward Better Automotive Packaging

To support this transition, SP developed a detailed guidance document titled Sustainable Packaging Specification Recommendations for Automotive Manufacturing Operations3. This voluntary framework outlines practical strategies for automotive OEMs and their suppliers to design and implement more sustainable, efficient packaging systems. It emphasizes material selection, reusability, and recyclability as key levers to reduce environmental impact across the supply chain. Some of the SP’s recommendations for OEMs and Tier 1 supplier include:

- Adopt Returnable Solutions

Use reusable containers and pallets wherever possible. Base decisions on Life Cycle Assessments (LCAs) to ensure they deliver environmental and financial value.

- Choose Smarter Materials

Select packaging materials that are widely recyclable, such as clear natural films or standard black plastics. Avoid hard-to-recycle foams and multi-material designs unless they are easy to separate and recycle.

- Improve Handling Efficiency

Design packaging for easy assembly and compatibility with automated handling systems like AMRs and robotic arms. This improves reuse and simplifies end-of-life processing.

- Build a Holistic Business Case

Consider not just packaging costs, but impacts on safety, logistics, emissions and waste. Sustainable packaging design often unlocks savings across the entire value chain.

Repurposed packaging enabled a battery manufacturer to save hundreds of thousands of dollars while keeping thousands of cubic yards of waste out of landfills. Source: Nefab

How One Battery Manufacturer Turned Waste Into Savings

When a design change made thousands of plastic transport trays obsolete, a leading LIB battery manufacturer faced a costly decision: discard the packaging and start from scratch, or find smarter, mor sustainable solution. Instead of sensing perfectly usable material to landfill; the company partnered with Nefab, who in turn:

• Redesigned the trays to fit the new battery shape while keeping the original tray footprint and in turn, ensuring compatibility with existing pallet system.

• Recycled the old trays, turning the recovered resin into new packaging materials.

• Reused the existing pallet bases and lids, minimizing the need for new components and extending the life of valuable assets.

The results were remarkable:

• $320,000 saved by reusing existing pallet components.

• $80,000 saved by using recycled plastic.

• 3,029 cubic yards of waste diverted from landfill.

• 175 tons of CO₂ emissions avoided.

• 6,883 barrels of petroleum saved.

This case shows how thoughtful packaging design can do more than protect products: it can drive measurable value across the supply chain while supporting long-term sustainability goals.

Packaging Design Matters

From lithium-ion batteries to lightweight automotive components, every product in the automotive supply chain depends on protective transport. But that protection doesn’t have to come at the environment’s expense.

As automotive production and EV demand grows, manufacturers have a unique opportunity to make packaging part of their sustainability strategy. By rethinking packaging design and embracing circular economy principles, OEMs can reduce waste, optimize logistics, and meet the growing demand for greener supply chains.

We save resources in supply chains for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

Solutions for the LIB and E-mobility & Automotive Industries

Sustainable Protection for Your Equipment

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Global Supply & Local Services

With over 250 engineers across more than 38 locations, working together in a global network, you can count on us for your next packaging project.