The Challenge: Overcoming High Costs, Safety Concerns, and Inefficient Shipping

The customer faced a unique set of conflicting requirements for their sensitive semiconductor equipment. The primary challenge was designing packaging that could survive the rigors of the global supply chain while remaining compatible with a highly controlled cleanroom environment.Key challenges included:

- Contamination Control: Materials had to be fully cleanroom-compatible, non-shedding, and easy to clean.

- Process Efficiency: The solution needed to be simple for operators to pack, unpack, and handle without compromising safety.

- Physical Protection: The high-value equipment required protection against G-forces and shocks during transport.

- Seamless Integration: The inner packaging layer needed to facilitate safe movement within the ISO 7 cleanroom after the outer layers were removed.

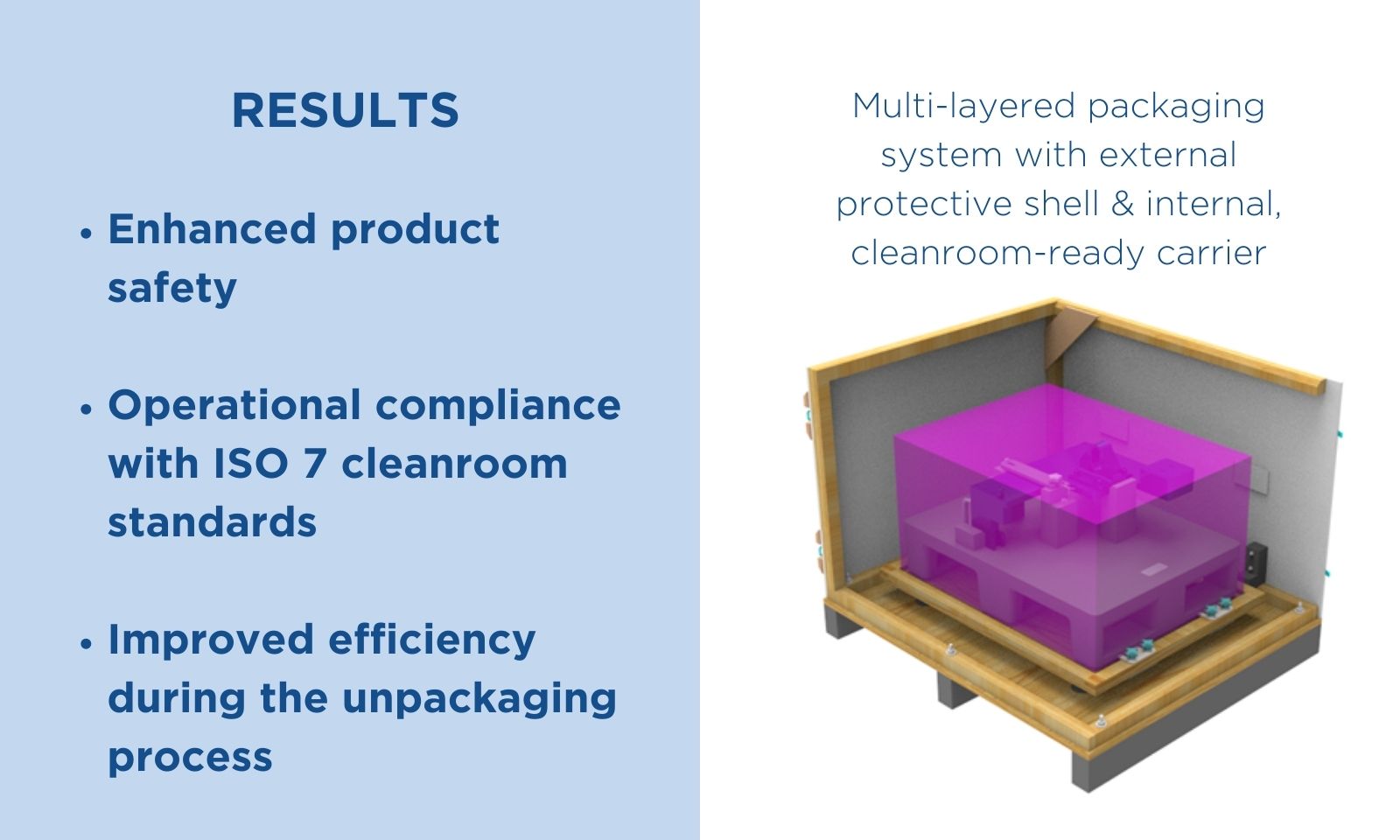

Nefab's Solution: Multi-layered packaging system with external protective shell and an internal cleanroom-ready carrier

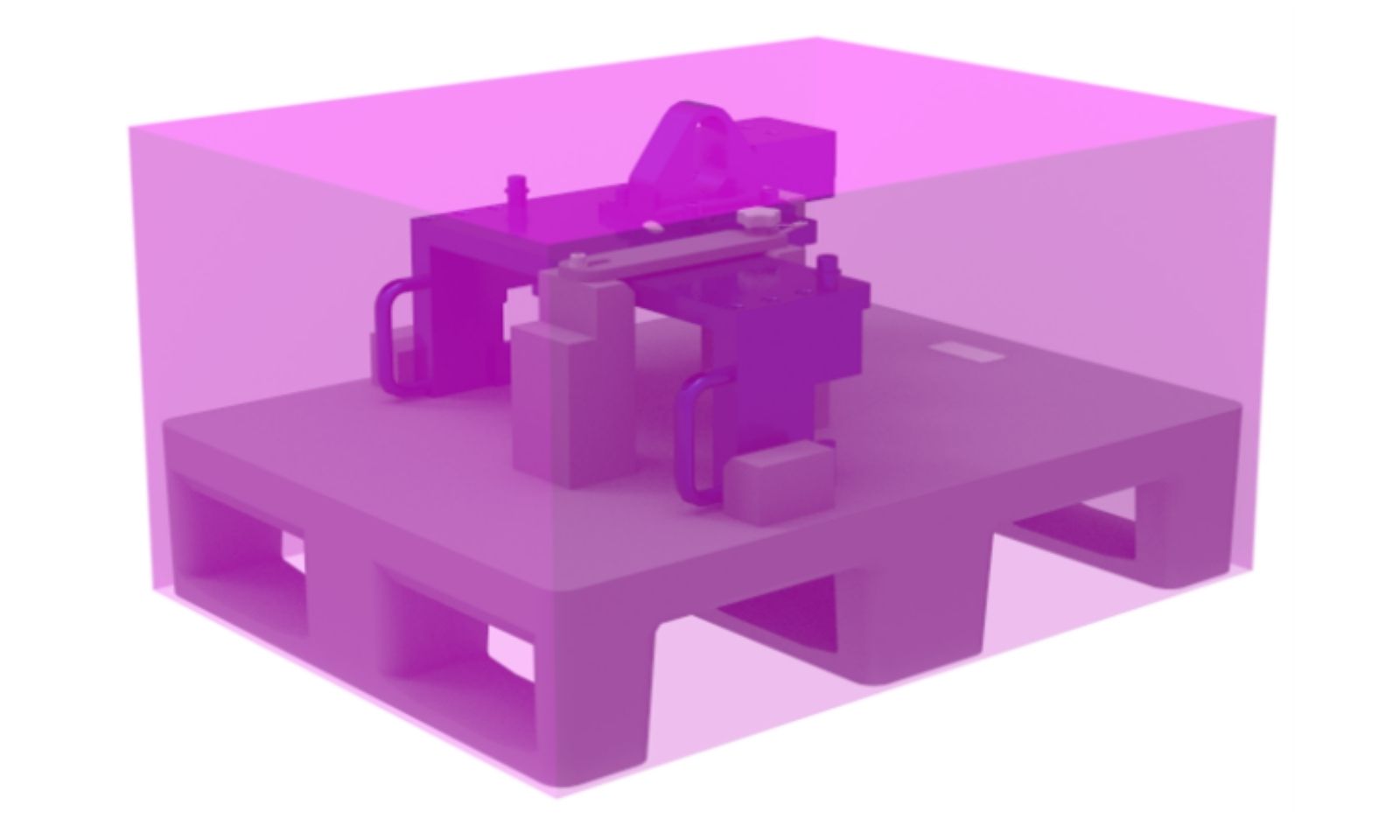

To address these complex needs of cleanroom ready packaging, a sophisticated, multi-layered packaging system was developed. The design separates the external protective shell from the internal, cleanroom-ready carrier, ensuring integrity at every stage of the journey.

Cleanroom-Ready Inner Layer: The core of the solution focuses on the "first layer" that enters the sensitive environment.

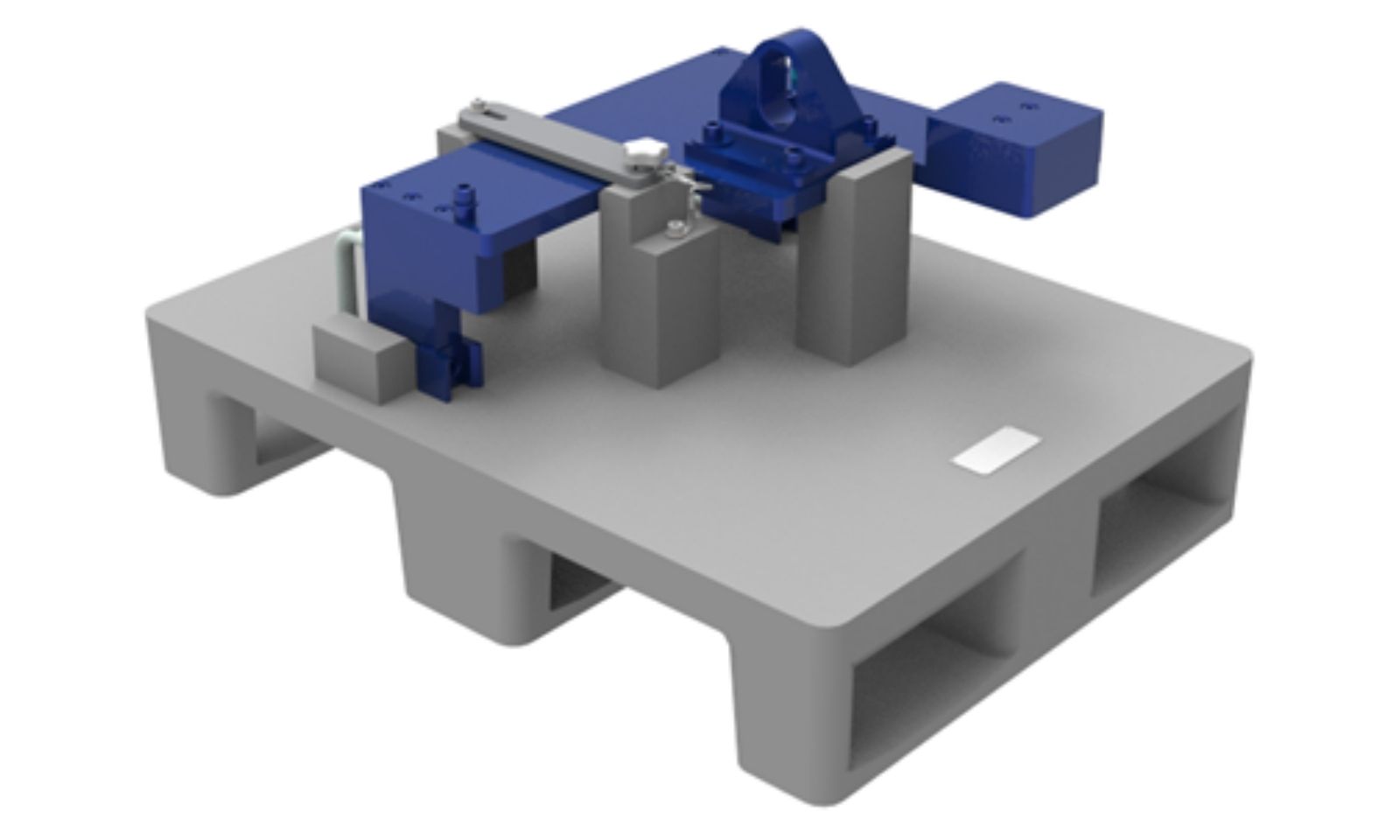

- Material Selection: High-Density Polyethylene (HDPE) pallets were chosen for their cleanliness and durability.

- Custom Fittings: Custom HDPE fittings were welded directly to the pallet’s top surface, eliminating the need for loose fasteners or potentially contaminating adhesives.

- Secure Locking: An integrated locking system ensures the product remains firmly fixed during handling but allows for controlled, easy removal by technicians.

- Contamination Barrier: The pallet and product are double-bagged using Low-Density Polyethylene (LDPE) cleanroom bags, preserving the sterility of the inner assembly.

Robust Outer Protection: The external packaging was engineered to handle the physical stresses of logistics while maintaining a professional aesthetic.

- White Coated Plywood: Selected for the outer box to provide a cleaner appearance than standard wood, even though this layer is removed prior to cleanroom entry.

- Shock Absorption: To minimize G-forces, the entire cleanroom assembly is mounted on a floating deck system equipped with rubber buffers. This provides critical damping to protect the sensitive equipment from vibration and impact.