- News & Insights

- 2026

- Optimized Foam Inserts for Cleanroom-bound Products

- Corporate News

- Customer Cases

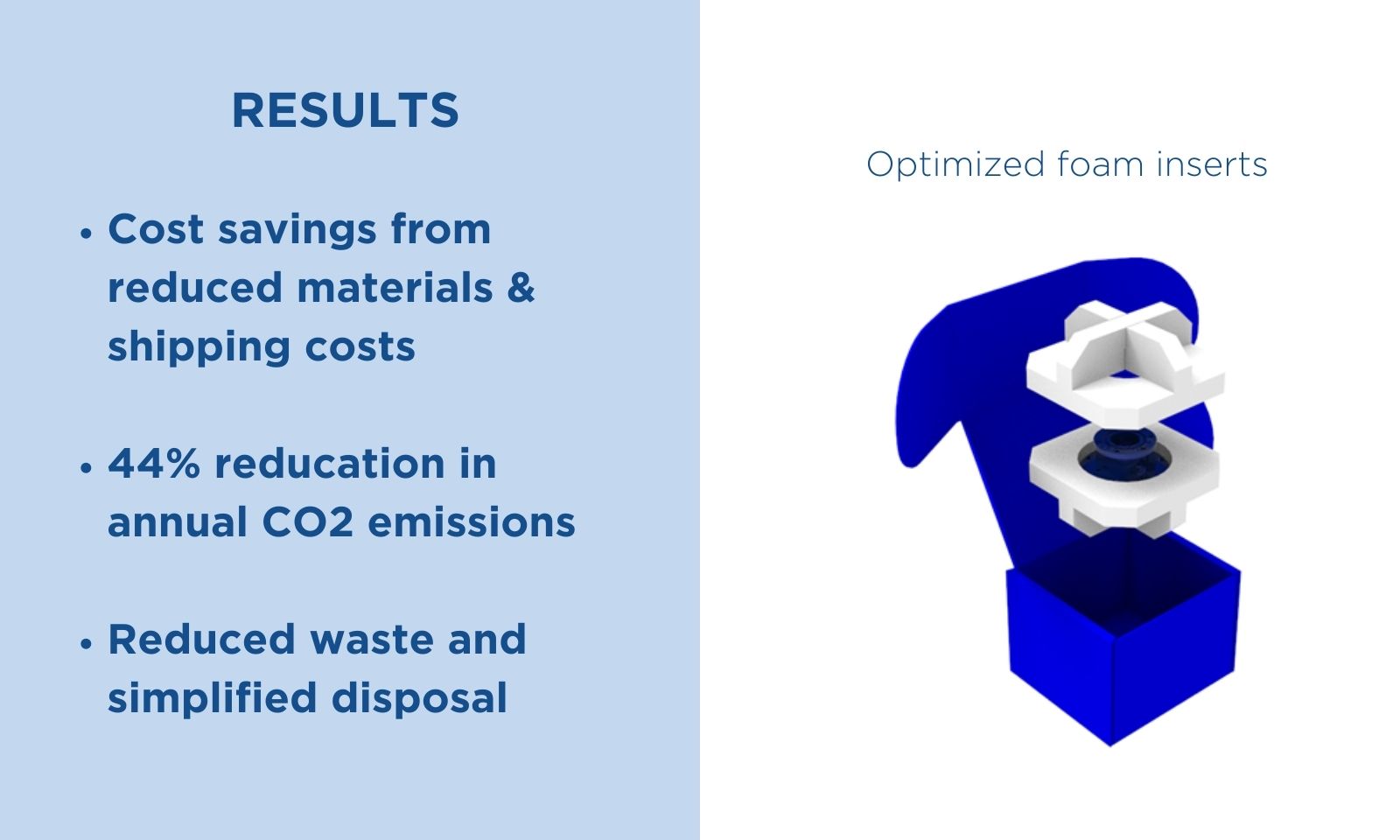

Optimized Foam Inserts for RPS Adapters

Our customer was using a legacy packaging design for the RPS (Remote Plasma Source) Adapters that was inefficient and costly. Their traditional "coffin-style" foam inserts consumed excess material, leading to higher expenses, more waste, and a larger carbon footprint. By re-engineering the packaging, we developed a streamlined, resource-efficient solution that provided the necessary protection while significantly reducing material use and volumetric weight.

The Challenge: Improving Legacy Packaging

In industries where precision and cleanliness are paramount, packaging is often a complex but critical component. The customer's existing design relied on large, solid foam inserts—often called "coffin-style" packaging—to secure their products.

While seemingly simple, this approach presented several underlying challenges:

- High Material Consumption: The design required a significant volume of foam, leading to elevated material costs.

- Increased Waste: More material usage directly translated to more waste at the end of the packaging's life cycle.

- Larger CO₂ Footprint: The production and transport of bulky materials contributed to a higher environmental impact.

- Inefficient Logistics: The heavy and large packaging increased the volumetric weight, driving up shipping costs and making handling more cumbersome.

The goal was clear: develop a one-way, cleanroom-compatible solution that maintained high protection standards but did so in a smarter, more resource-efficient way.

Nefab's Solution: Engineering Efficiency into Design

Our core principle is that optimization should be embedded in every aspect of a project, from materials and production to logistics. We approached this challenge by moving away from the brute-force protection of "coffin-style" inserts and toward a more intelligent and streamlined design.

The new solution focused on several key improvements:

- Strategic Material Reduction: Instead of filling empty space with foam, we engineered a solution that uses precisely placed supports and cushions. This provided the same level of protection while drastically cutting down on the amount of material needed.

- Design Streamlining: The entire packaging assembly was re-evaluated to remove unnecessary components and simplify the structure. This made the packing and unpacking process more straightforward for operators.

- Volumetric Weight Optimization: By reducing the overall size and weight of the packaging, we lowered its volumetric weight. This directly addresses the high cost of shipping, especially for sensitive components that require careful handling.

The result was a one-way, cleanroom-compatible solution that meets all protection requirements without the excess baggage of the previous design.

"Optimization is always at the core of our work. The new design is a perfect example of how we can achieve superior protection in a more straightforward and resource-efficient way."

Results: A Lighter & More Efficient Solution

The shift to an optimized design delivered significant and measurable benefits for the customer, demonstrating that better engineering leads to better business outcomes.

- Reduced Material Consumption: The new design uses substantially less foam and other materials, leading to direct cost savings on every unit shipped.

- Lowered CO₂ Footprint: By minimizing material use and creating a lighter package, the solution's overall environmental impact was significantly reduced.

- Decreased Shipping Costs: A lower volumetric weight translated into tangible savings on logistics and transportation expenses.

- Reduced Waste: Less material going into the package means less waste coming out at the destination, simplifying disposal and supporting the customer's sustainability goals.

This project successfully proves that legacy designs are not always the most effective. By challenging the "more is more" assumption of traditional "coffin-style" inserts, we were able to deliver a packaging solution that is not only more cost-effective and sustainable but also easier to handle. For the customer, this initiative streamlined a critical part of their supply chain, reducing both operational costs and environmental impact without compromising the safety of their high-value products. It stands as a testament to how thoughtful design can create powerful efficiencies.

Ready to Take the Next Step?

Switching to our optimized foam inserts helped our customer to lower their annual CO2 emissions by 44%.

Talk to Our Experts

Explore our Semicon Industry Solutions

See our comprehensive packaging and logistics services designed specifically for the medical sector.

Explore Semicon Industry Solutions

See our comprehensive packaging and logistics services designed specifically for the medical sector.

Explore More Insights

Additional Resources