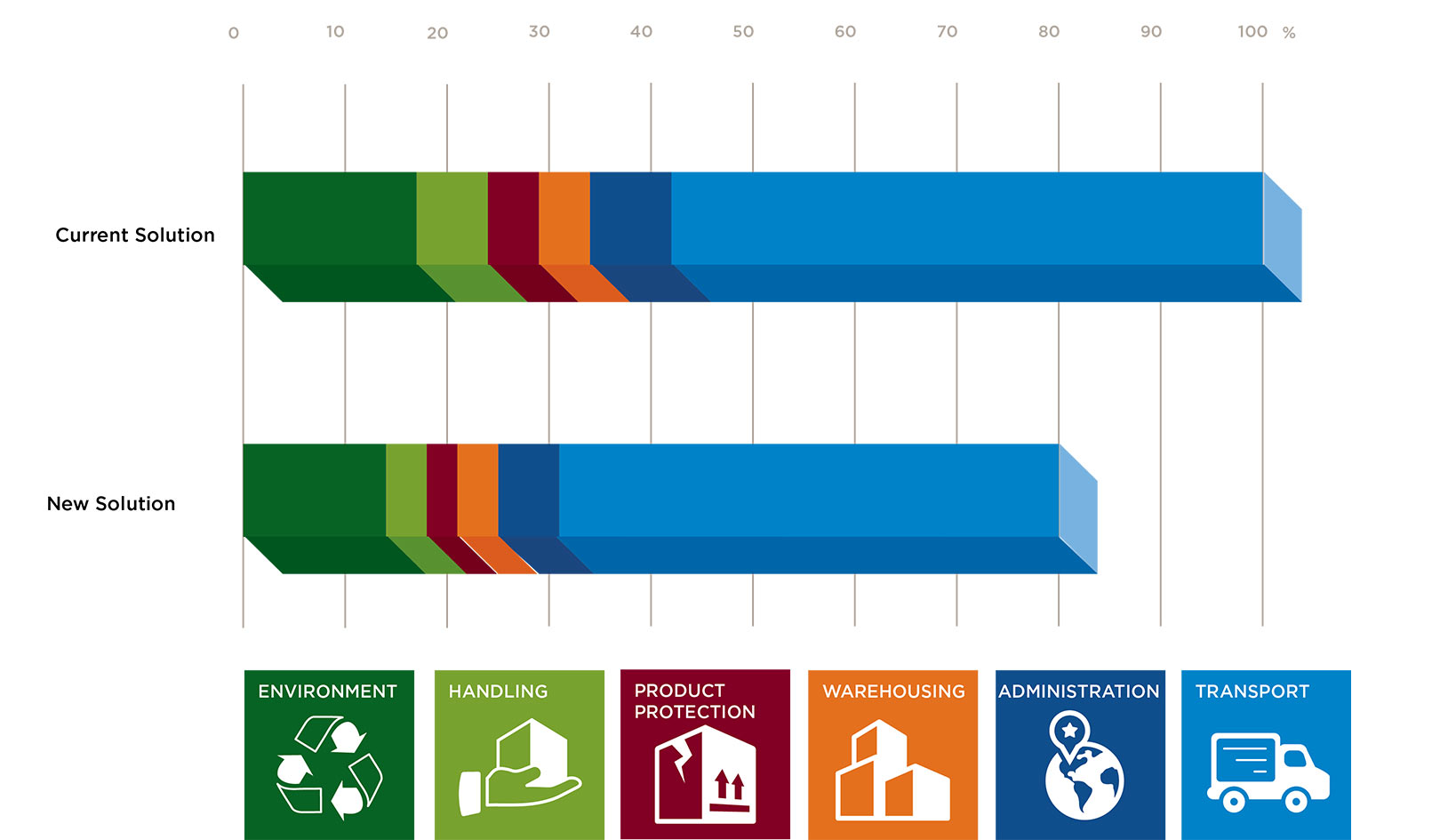

Global packaging solutions that reduce total cost

Nefab’s Total Cost Approach ensures that your packaging solution is optimized to reduce total cost in your supply chain. We evaluate specific cost areas within your logistics flows, such as transportation and warehousing, and identify ways in which a smarter packaging solution can make a difference for your bottom line.