NEWS & INSIGHTS

The circular economy and the 3R's

How plastic packaging can be sustainable

We often hear that plastics are not sustainable - but is that always the case?

It’s widely known that the world’s current disposal system has not been able to adapt to the growing market’s dependance on plastic packaging, while failing to capture its economic benefits.

In fact, more than 40 years after the launch of the first universal recycling symbol, just 14% of the plastic packaging used globally is recycled, while 40% ends up in landfills and 32% in ecosystems, with the remaining 14% used for incineration or energy recovery (The SustainAbility Institute).

The good news is that plastics are sustainable when they are circular. By applying the circular economy and its three main principles – the 3R’s: reduce, reuse, and recycle –, it is possible to save both environmental and financial resources in industrial plastic packaging worldwide. Here is how.

Reduce

Designing out plastic waste and pollution

Plastic materials are often chosen for packaging applications that require toughness and impact resistance thanks to their enhanced durability, which in turn guarantees product safety. The significant light weight and design freedom make it a versatile material that reduces the costs of shipping and transportation. More importantly, these features allow for considerable energy and space savings, besides reducing cost and CO2 emissions.

Reuse

Keeping plastics in continuous use

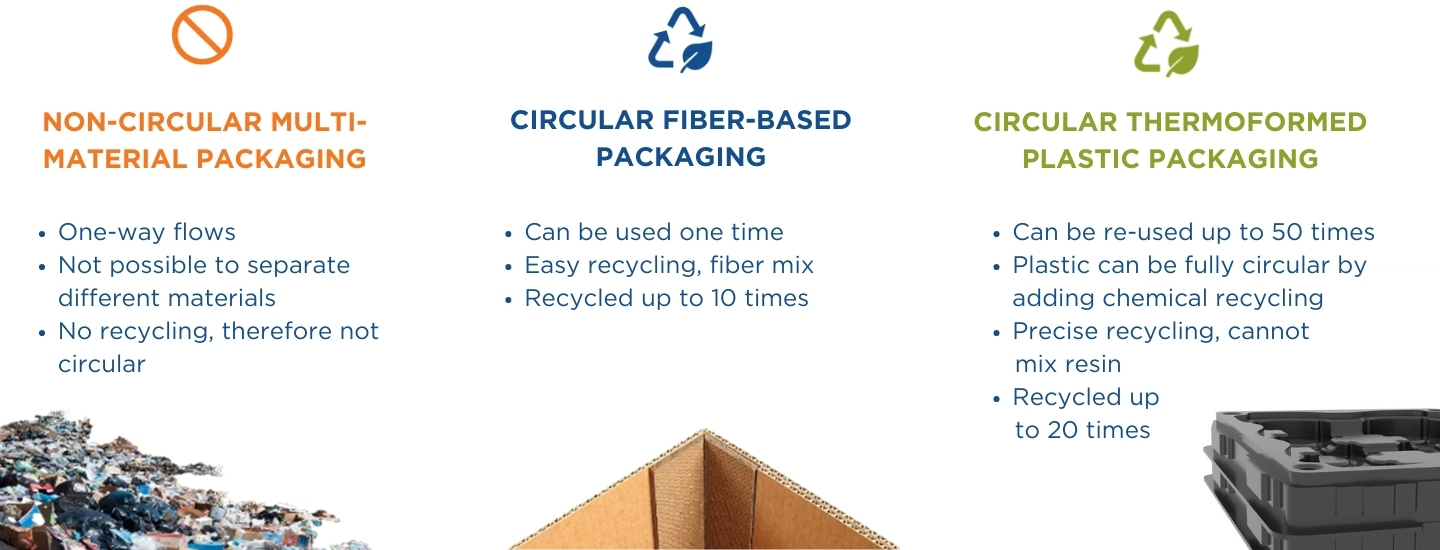

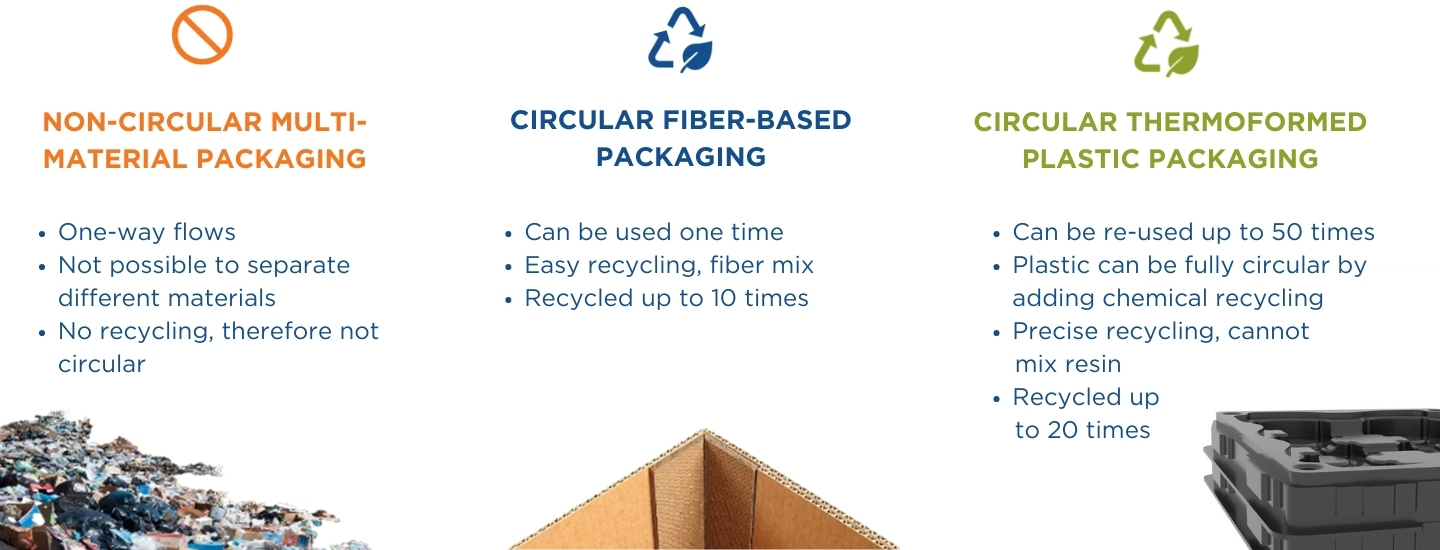

Understandably, not all products can be packed in recycled packaging due to high product protection demands. However, it is estimated that at least 20% of plastic packaging can be reused multiple times until its quality deteriorates (ScienceDirect). This concept has been widely used by transportation companies that use returnable containers and pallets to significantly lower their environmental footprint (Reusable Packaging Association). And thermoformed plastics are particularly suitable for return and circular flows. Here is an example.

CIRCULAR FLOW OF THERMOFORMED PLASTIC SOLUTIONS

Recycle

Regenerating natural systems

A properly functioning recycling market creates a circular, closed-loop ecosystem that helps to divert both landfills and ocean-bound plastic. A crucial step towards this goal is to recycle plastic that cannot be reused anymore. in fact, most plastic packaging can be fully recyclable up to 6 times, if disposed of correctly (British Plastic Federation), thus enormously reducing carbon emissions.

In conclusion, going back to the initial question - can plastics be sustainable? The answer is – yes, they can. By focusing on the circular economy and the 3R’s, it is possible to develop highly protective and sustainable plastic packaging solutions. All industries can benefit from this positive change, and connect better with their customers, audiences, and sustainability goals.

At Nefab, with a continuous focus on eco-friendly materials, we are finding new ways to achieve greater sustainability in our solutions and smarter ways to reduce the environmental impact. Together, we can pave the way for a future with less packaging waste for our customers, society, and the environment.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our circular plastics solutions.

LEARN MORE

Plastic packaging solutions: Nefab offers a wide range of custom engineered plastic packaging solutions that drive efficiency, reduce environmental impact, and optimize supply chain costs.

Thermoforming: A cost-effective plastic forming process ideal for creating lightweight, reusable packaging with rapid turnaround times and competitive tooling costs.

Injection molding: A precise and efficient manufacturing process for producing plastic packaging solutions with complex shapes in a repeatable way.

GreenCALC: Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions