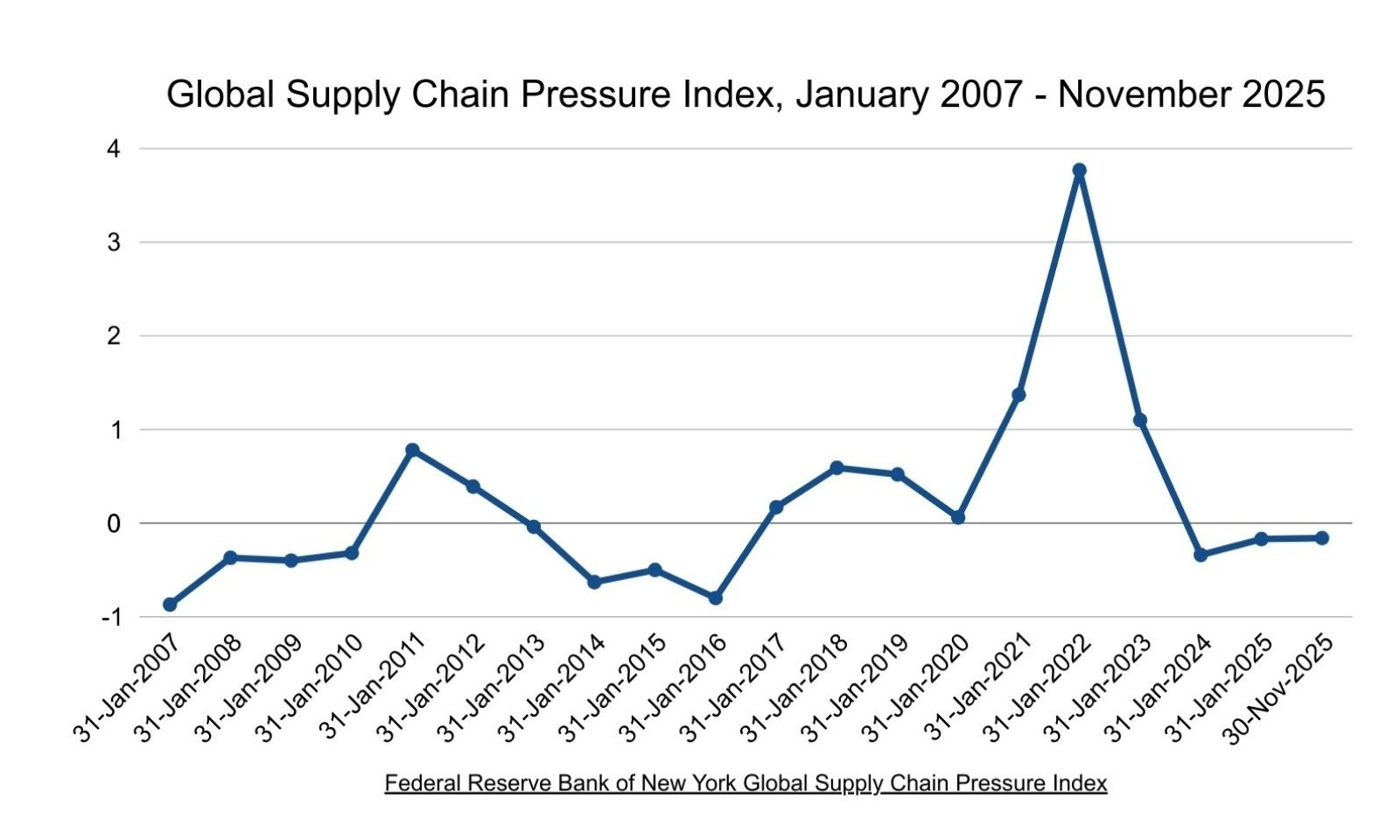

2025 was a year of “reset” for global supply chains1. After several years of almost constant disruption, from global pandemic to economic shifts and geopolitical instability, companies began rethinking how they operate2. Recent research among senior executives shows just how deeply they feel the pressure: three out of four global leaders say political risks have affected their supply chains in the past two years, and more than two in three report a negative impact3.

Instead of asking how to fix each disruption, companies began asking how to build systems where disruption matters less. Resilience is about managing risks, not eliminating them. In 2025, the mindset shifted from reactive problem-solving to proactive planning. Let’s take a closer look at the trends that defined this transition.

After years of volatility culminating in a 2022 peak, global supply chain pressures eased significantly, setting the stage for the resilience-focused strategies that defined 2025.

Packaging Becomes Strategic

Across sectors, packaging started to play a much more strategic role. Instead of being viewed primarily as a cost, it became a tool for improving efficiency and consistency, especially within global, multi-regional networks. Companies increased their investments in:

- Modular systems that can be rolled out quickly across sites, allowing faster responses to disruptions and easier scaling.

- Standardized quality across regions to reduce inconsistencies, improve performance, meet regulatory requirements, and lower supplier risk.

- Reusable and returnable solutions that keep materials in circulation and strengthen supply resilience through shorter lead times and better visibility across the logistical flows.

The Sustainable Packaging Coalition pointed out this shift, saying that packaging design, materials, and recovery systems now support resilience, sustainability, and regulatory needs as much as cost optimization4 .

Sustainability Became More Measurable

The way companies approach sustainability has changed significantly. Broad commitments were no longer enough. Instead, companies focused on measurable impact and used data to guide real improvements in their packaging choices. The biggest shifts included:

- Wider use of Life Cycle Analysis (LCA) tools and digital platforms to compare materials and designs 5.

- A continued move toward fiber-based packaging and cushioning in place of virgin plastics 6.

- Growing interest in circular systems, often supported by local recycling or recovery partnerships.

It is also worth noting that stronger regulatory requirements, especially in Europe, accelerated this change7 . New reporting and compliance requirements pushed companies to back up their sustainability goals with verified data.

GreenCalc™ is Nefab’s Life Cycle Analysis (LCA) tool designed to measure and quantify both the financial and environmental impacts of packaging and logistics across a customer’s supply chain.

Regionalization Reshaped Supply Chains

The move toward regionalization gained momentum throughout 2025. More manufacturers brought production closer to end customers to reduce risk, shorten lead times, and increase control over day-to-day operations.8

With this change, several priorities became even more important:

- Reliable access to regional and local packaging, engineering, and testing capabilities

- Partners who offer global expertise combined with strong regional presence

- Packaging solutions tailored to local regulations and market needs

With supply chains becoming more regionalized, packaging providers with strong local infrastructure and technical know-how became strategic allies.

According to a report from the World Economic Forum and Kearney, more than 90% of manufacturing executives say regionalizing their supply chains has become a top priority (Source: World Economic Forum).

Smart and Connected Packaging Scaled Up

Digitalization took a major step forward in 2025. IoT-enabled packaging gained traction9 , and the ability to capture real-time data quickly became a competitive advantage.

Today, connected packaging now supports:

- Real-time visibility into handling conditions during transport

- Better inventory accuracy and smoother, more automated warehouse operations

- Early-warning alerts that help protect high-value equipment10

As more companies integrate sensors and cloud-based monitoring tools into logistics, smart packaging became an integral part of modern supply chain management.

A Beginning of a New Era?

The changes seen in 2025 mark a clear shift. Supply chains are being rebuilt for resilience, sustainability, and agility, not just efficiency. With strategic packaging, regionalization, and digitalization accelerating, the foundation is set for a smarter and more adaptable supply chain landscape in 2026 and beyond.

We save resources in supply chains for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

Sustainable Solutions

Engineered packaging for sustainable supply chains

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Global Supply & Local Services

With over 250 engineers across more than 30 locations, working together in a global network, you can count on us for your next packaging project.