The Challenge: A Sustainable and Innovative Solution for Shipping Gas Insulted Switchgears

The customer faced several challenges in their packaging process when they had previously utilized cleated wooden crates from a local supplier. The packaging provided inadequate protection for one of their large components during transport between countries. In addition, their local supplier was unable to meet the company’s stringent design specifications or propose an innovative solution.

The customer also shifted its business model, requiring the transportation of just one critical component rather than the completed unit. This change introduced new complexities and increased the importance of optimized packaging. The new packaging needed to:

- Allow for quick and simple unpacking and repacking in another country, where additional parts were added.

- Align with the end user’s sustainability standards by offering a long-lasting, eco-friendly solution.

- Optimize transportation costs and reduce environmental impacts.

With the local supplier unable to meet these needs, the customer required a more professional, long-term, and cost-effective alternative capable of aligning with its sustainability goals.

Nefab's Solution: Customized ExPak Solution for Strength, Protection, and Efficiency

Nefab addressed the customer's needs by designing a highly customized ExPak solution, crafted to deliver strength, protection, and efficiency. The features and implementation included:

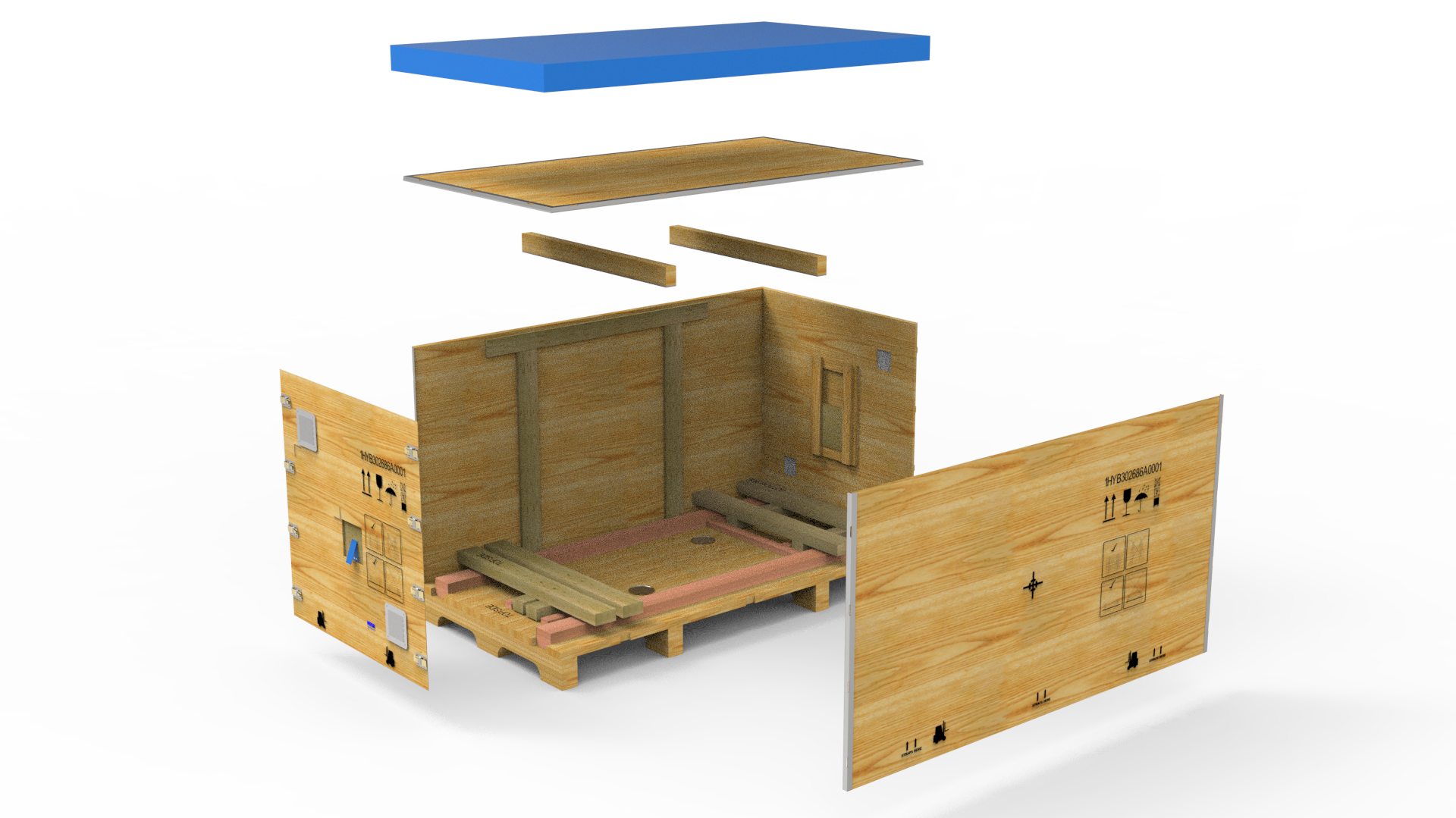

- Lightweight ExPak S Design: A strong, durable packaging solution featuring sleeves and a wooden pallet for easy handling and maximum container efficiency.

- Protective Fitment: The component was securely attached to a pinewood fitment and locked on the pallet using foam and a VCI (Volatile Corrosion Inhibitor) bag to prevent any movement.

- Simplified Assembly: Spring clip locking mechanisms allowed for effortless assembly and disassembly, enhancing operating efficiency.

- Waterproof Outer Layer: A durable cover protected the packaging from water ingress, and the entire box was strapped for safe transit.

- Seamless Branding: The new packaging included the company’s logo and essential safety markers, improving both functionality and branding.

The solution streamlined the packaging process, enabling the bare mechanism to be transported securely between countries before undergoing final assembly and shipment to end customers.