The Challenge: Eliminating Virgin Plastics from Medical Diagnostics Equipment Packaging

Historically, the client's supply chain relied on PE foam for packaging, a material made from virgin plastics that presented significant environmental challenges. While PE foam provided adequate cushioning and protective properties, it was not recyclable and contradicted the client's shift toward more sustainable practices. Additionally, the use of PE foam increased packaging volume, adding to transportation inefficiencies and heightened carbon emissions throughout their global supply chain.

The client needed a solution that:

- Completely eliminated virgin plastics from their packaging materials for Medical Diagnostic equipment .

- Maintained or exceeded current packaging performance in terms of cushioning and protection.

- Addressed varying environmental conditions (e.g., humidity).

- Reduced transportation inefficiencies caused by bulky packaging.

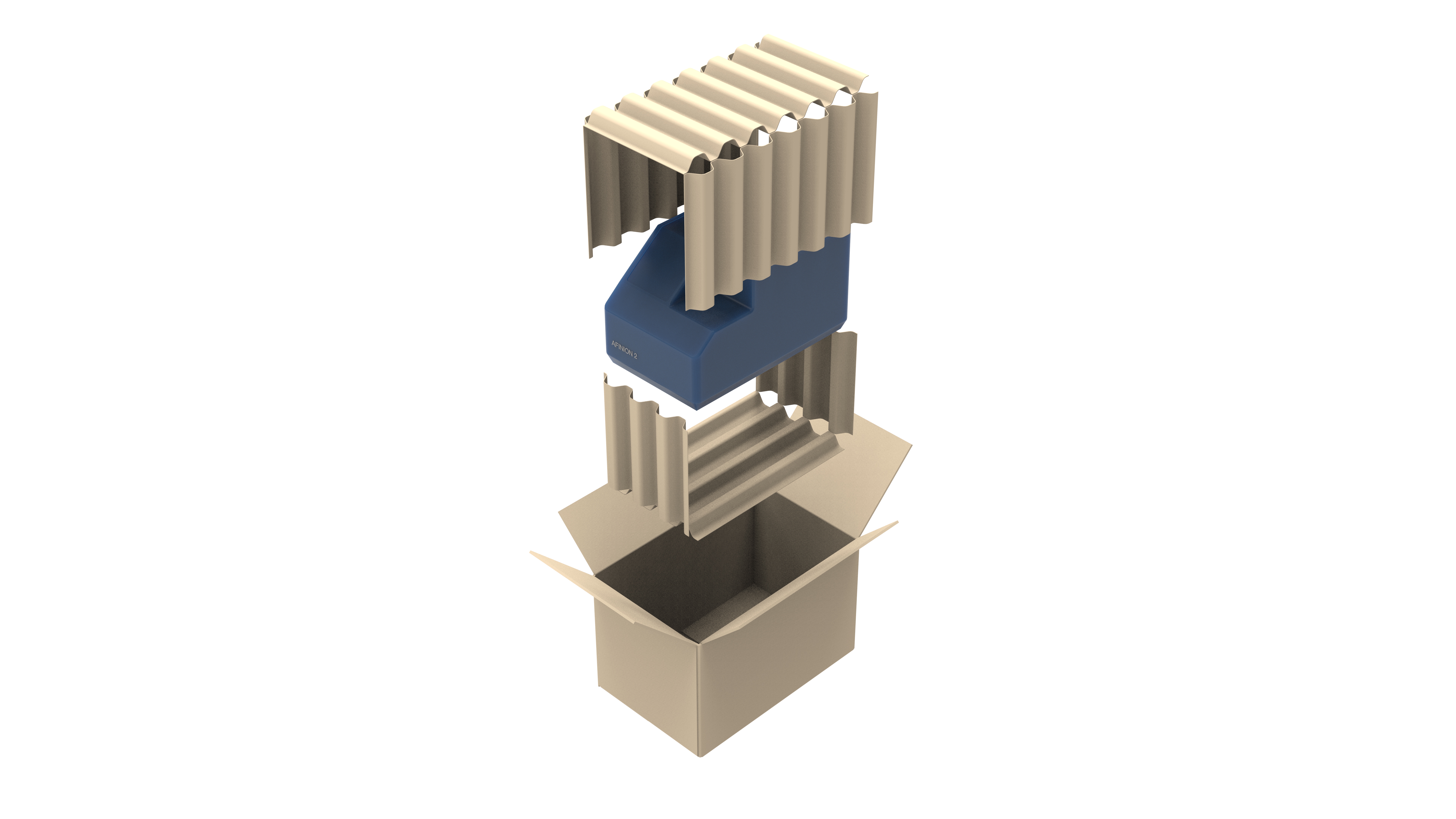

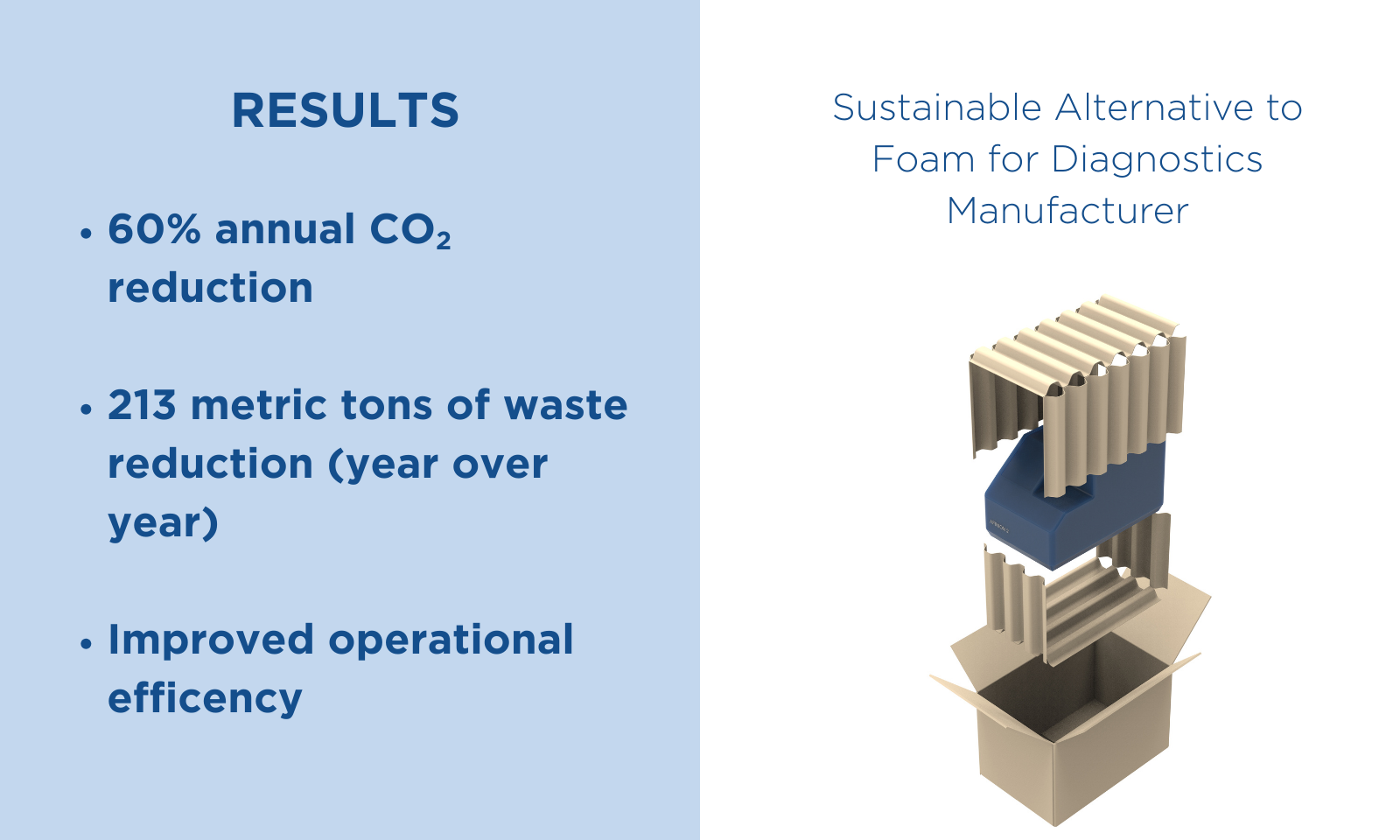

Nefab's Solution: Redefining Sustainable, Efficient, and Protective Packaging with FiberFlute

Nefab's team of engineers developed FiberFlute, an innovative, 100% recyclable packaging material that replaced the client’s PE foam entirely. Designed with sustainability and functionality in mind, the FiberFlute solution seamlessly addressed the client’s requirements.

Key features of the FiberFlute design included:

- Enhanced Sustainability: Made from recyclable materials, FiberFlute eliminated virgin plastics, making it a more eco-friendly alternative.

- Optimized Protection: The material provided consistent cushioning, ensuring the delicate multi-assay analyzers were protected even in humid or challenging conditions.

- Improved Space Efficiency: The design reduced packaging volume, optimizing transportation space and subsequently lowering carbon emissions throughout the supply chain.

- Stacking Strength: The sturdy design improved overall stacking strength, allowing for safer and more efficient storage and transit.

Nefab worked closely with the client to develop a custom implementation plan, ensuring that the solution met their specific operational demands while contributing to their sustainability goals. The FiberFlute solution integrated seamlessly, maintaining product integrity from manufacturing facilities to healthcare environments.