The Challenge: Cost, Safety, and Efficiency for C-Arm Shipping

The client presented several key challenges with their existing packaging approach:

- High costs: The existing packaging materials and design significantly increased the overall cost of delivery.

- Product safety: Ensuring shock protection for the sensitive c-arm equipment during transportation was a pressing concern.

- Ease of installation and disassembly: Transporting and unpacking c-arms in hospitals was difficult. Narrow hallways, lack of loading docks, and the need for tool-free setups made the process cumbersome.

The client needed a system that could lower costs, provide superior protection, and streamline delivery in challenging environments.

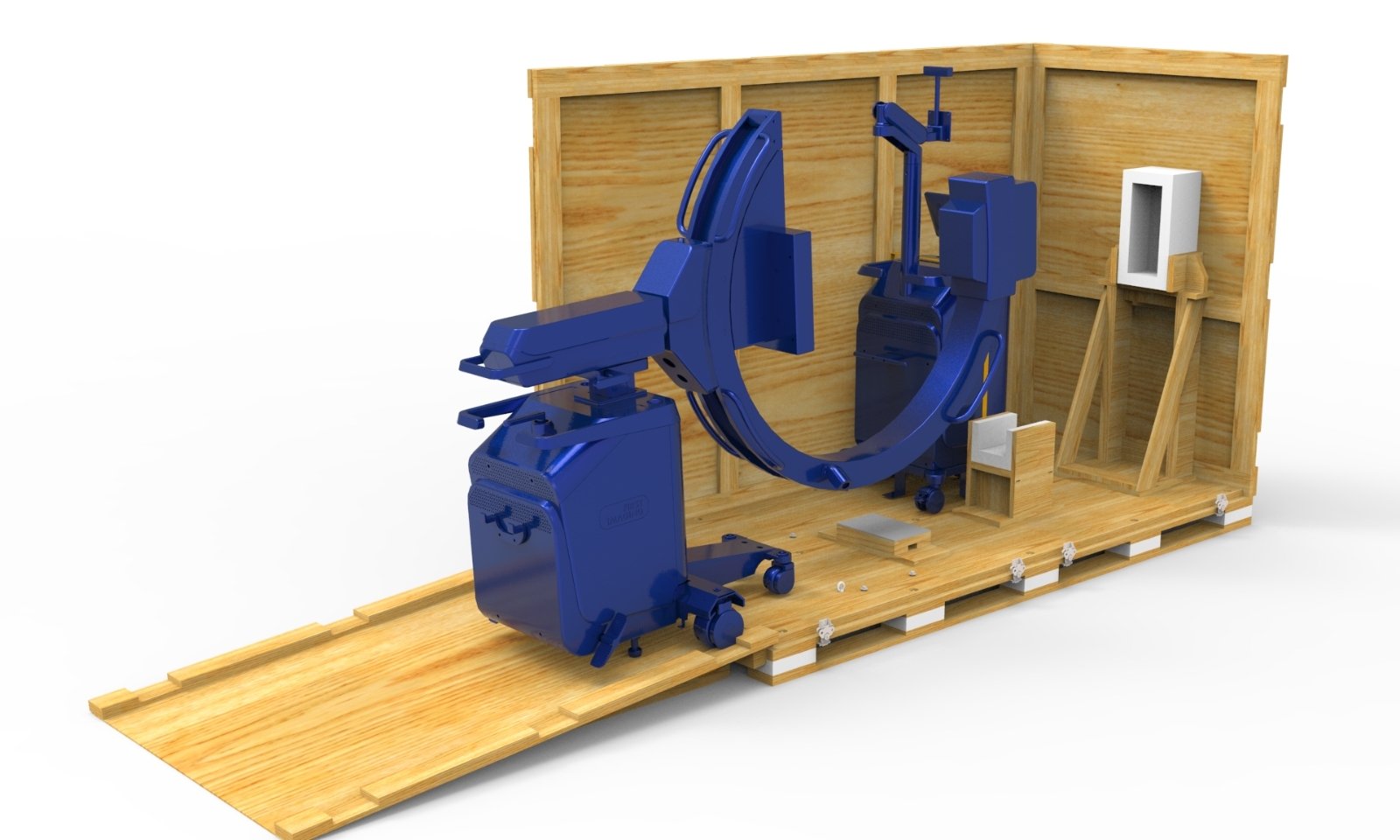

Nefab's Solution: Innovative and Sustainable Nail-less Solution and Ramp

The vendor innovated a comprehensive solution that addressed each of the client’s pain points:

- Nail-less solution + ramp

The nail-less design allowed for easy assembly and disassembly without the need for tools, aligning perfectly with the hospital’s logistical challenges. A ramp was also added to simplify transport, making it possible to move the equipment efficiently through narrow halls.

- Lightweight materials

By using a design with 20% less empty packaging weight, the overall shipping cost was significantly reduced while maintaining durability and protection standards.

- Enhanced shock protection

Leveraging EPE cushion pallets to replace the previously used skidmates provided excellent shock absorption at a lower cost.

- Internal wooden fitments

The addition of internal wooden fitments secured the c-arm effectively, ensuring it remained stable and protected throughout transit.

This holistic approach ensured the client’s specific requirements were met while adding significant value to their logistics process.