The Challenge: Standardizing Packaging for Turbine Blades

The customer faced inefficiencies stemming from non-standardized crates used for turbine blade maintenance. The turbine blades varied in size and configuration, leading to inconsistent crate dimensions and qualities. This lack of uniformity complicated storage and transportation logistics, consuming additional space and resources, and resulted in higher logistics costs. Containers couldn't be fully utilized, increasing shipping expenses, and the packing process onsite was highly labor-intensive and time-consuming.

They needed a packaging solution that simplified onsite operations, enhanced transportation efficiency, and aligned with their sustainability goals.

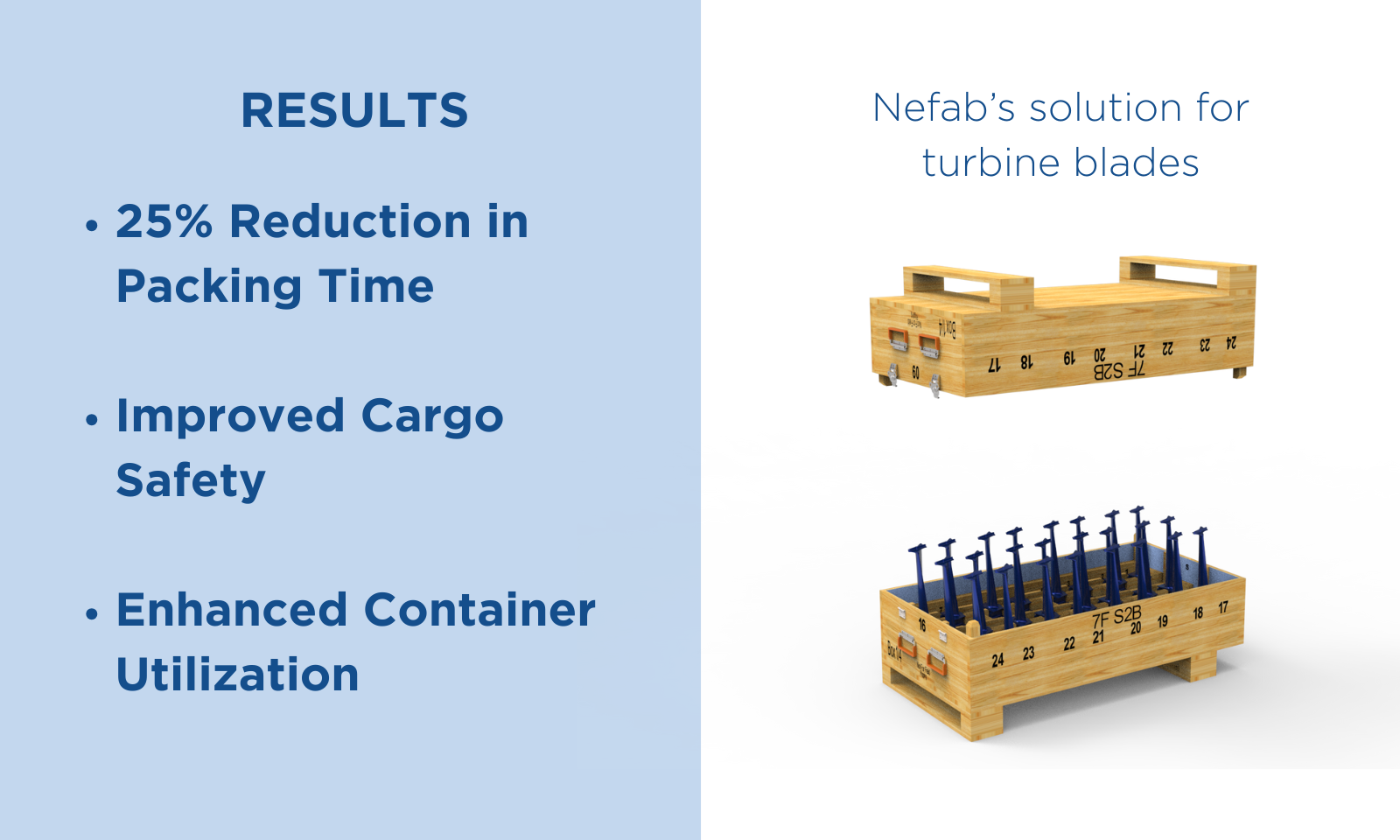

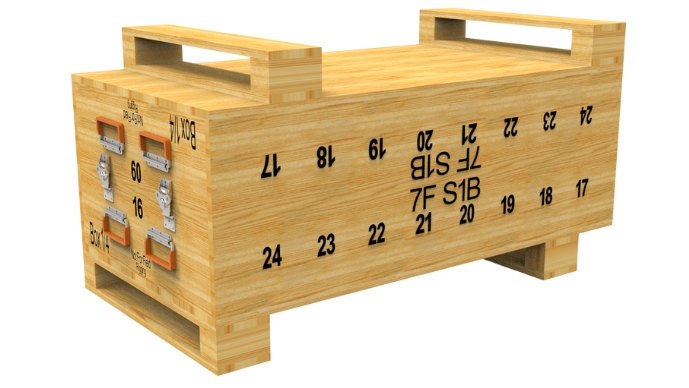

Nefab's Solution: Innovative Pinewood Crate Design

To address these challenges, our team designed an innovative pinewood crate with plywood inner fitments. The crate featured a mirrored configuration connected by link locks, allowing workers to easily remove the top crate for damaged blades and retrieve new blades from the bottom crate. This streamlined the onsite packing and unpacking process. Beyond functionality, complete standardization in size and quality was implemented. This reduced the complexity of operations, saving time and labor resources by limiting variations that workers needed to manage. The reconfigured crate dimensions were optimized for transport, maximizing container utilization and reducing required resources. This also minimized environmental impact, contributing to the customer’s sustainability objectives.