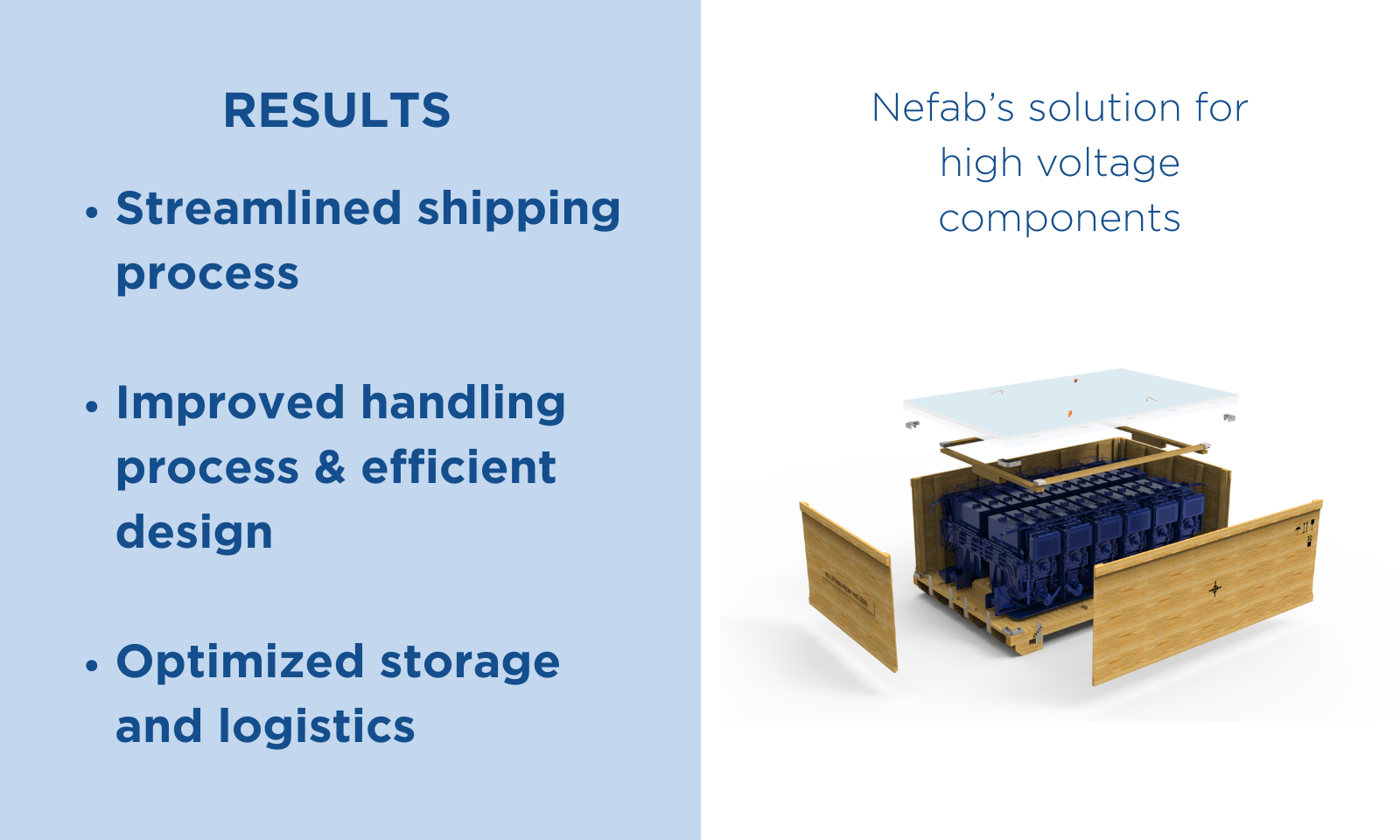

The Challenge: Modular Packaging Redesign for High-Voltage Equipment

A leading energy company came to Nefab looking to improve its existing packaging. The key issue was that with the existing dimensions, the product was too wide to fit in standard shipping containers, requiring reliance on flat racking, which caused inefficiencies and higher shipping costs. Additionally, the packaging couldn't be flat-packed, creating a more cumbersome handling and storage process. The customer needed a robust, modular solution that could optimize shipping, storage, and operational efficiency while ensuring the safety of their high-voltage equipment.

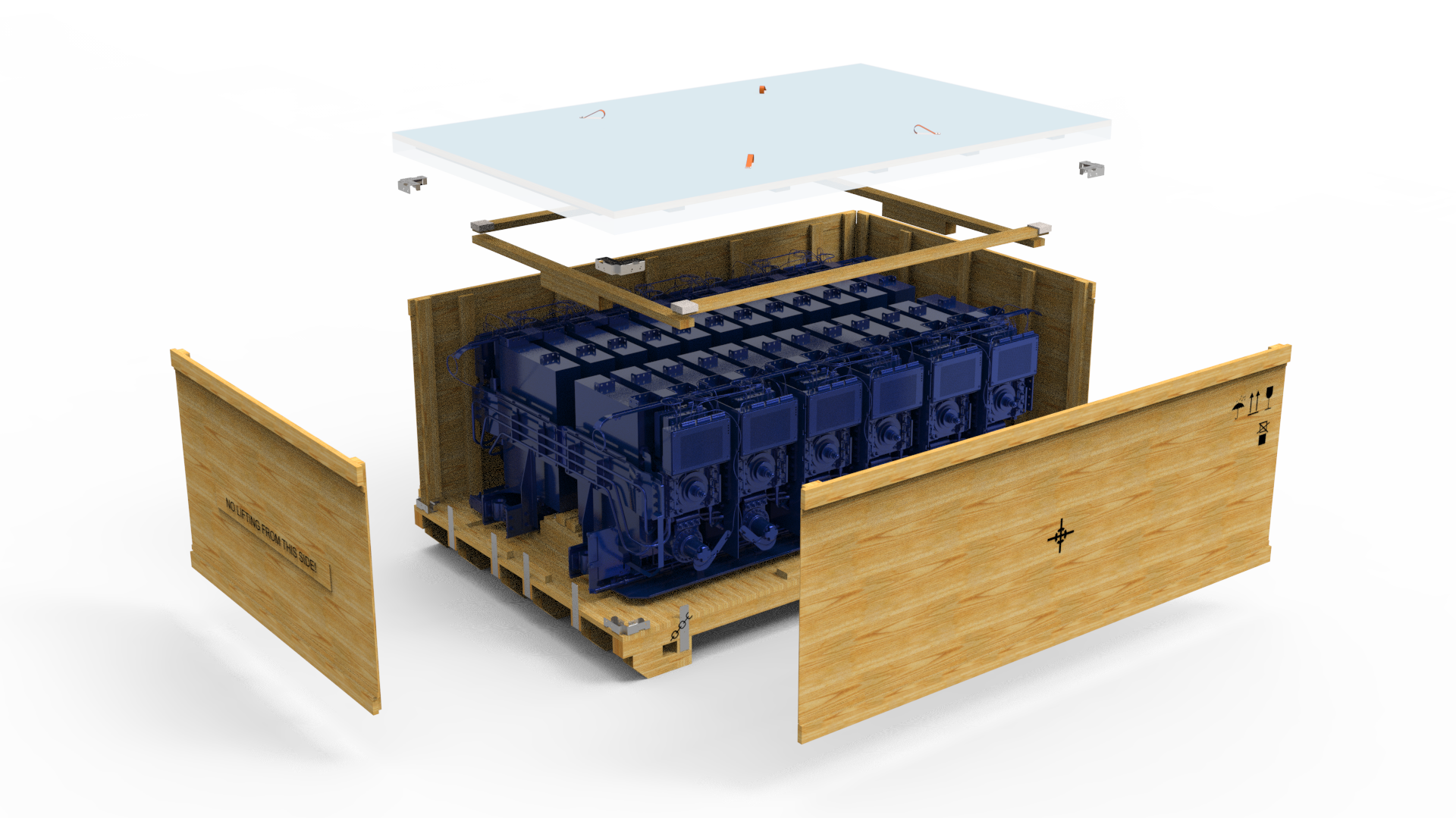

Nefab's Solution: Enhancing Efficiency, Protection, and Sustainability with CratePak

To tackle these challenges, CratePak was selected as the optimal solution. Designed with container optimization in mind, CratePak addressed the previous shortcomings with a smarter, more efficient design. To tackle these challenges, CratePak was selected as the optimal solution.

Key benefits:

- Compact Design: CratePak was tailored to fit within standard shipping containers, reducing the need for flat racking and improving logistics efficiency.

- Improved Handling: The packaging enabled easier assembly and disassembly, requiring no tools and significantly reducing manual labor.

- Enhanced Protection: The high-voltage components were safeguarded with CratePak's exceptional durability and stacking capabilities.

- Collapsible Functionality: When not in use, CratePak could be flat-packed, saving valuable storage space.

- Safety and Sustainability: The simpler handling process improved worker safety, while the efficient, reusable design aligned with sustainability goals.