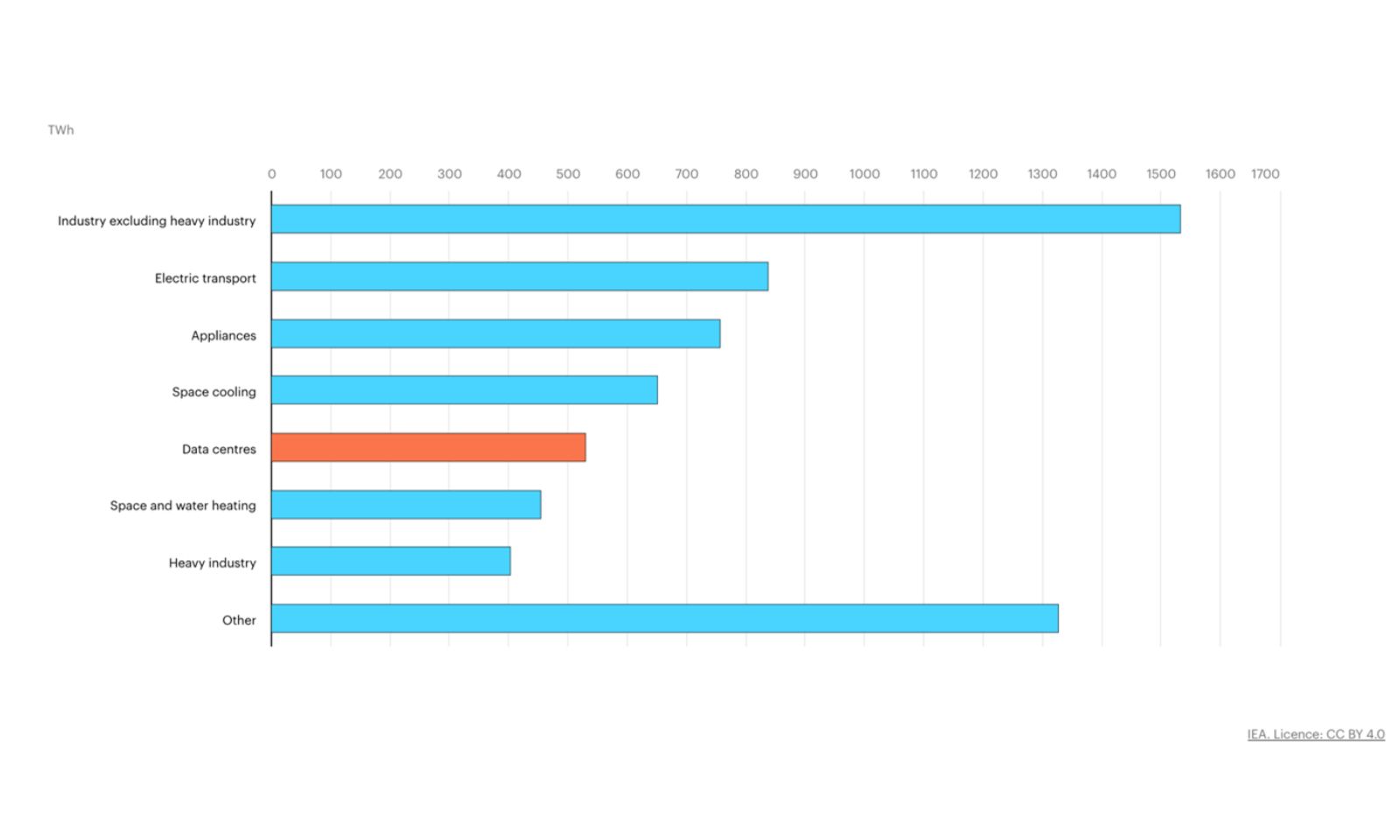

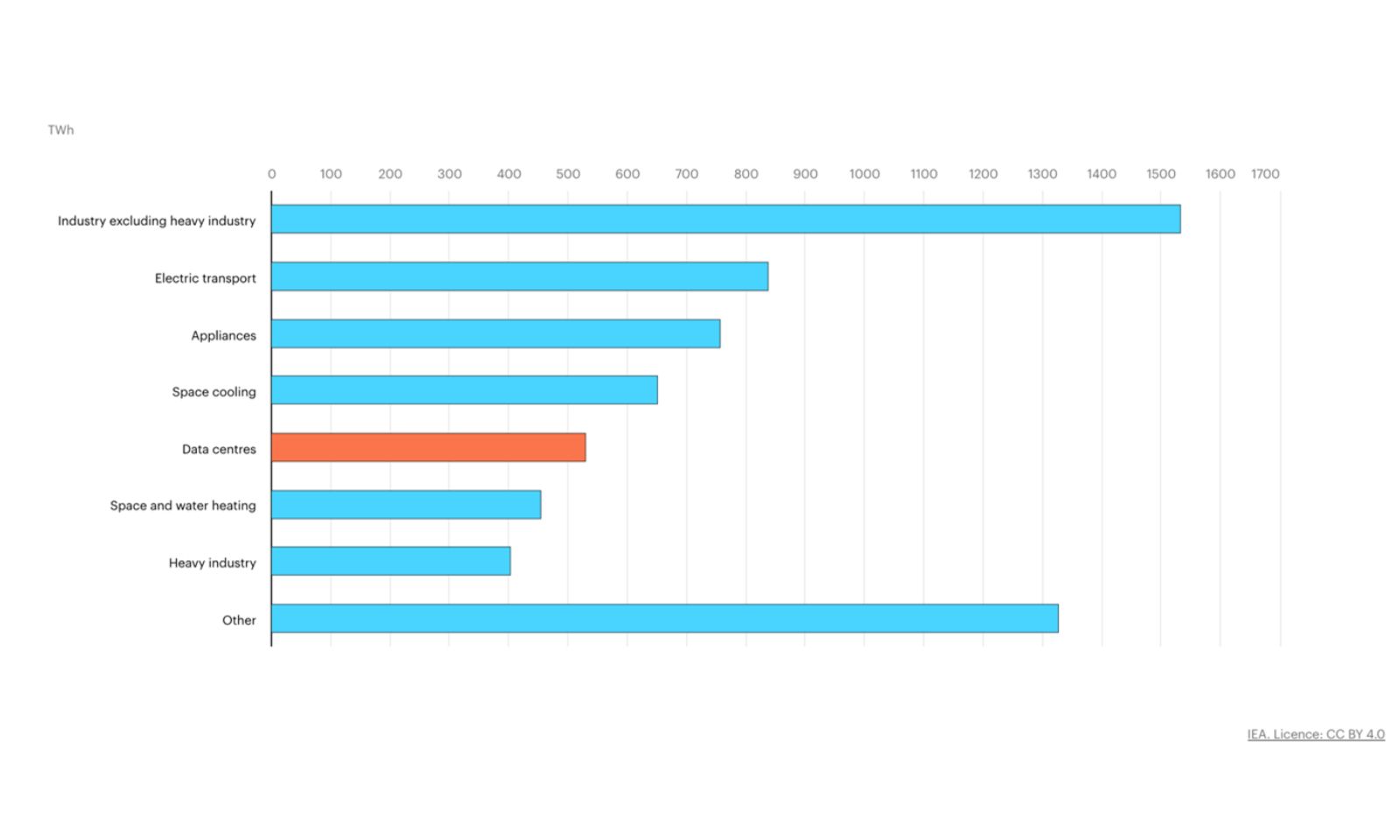

Global electricity demand jumped another 4% in 20241, a strong, continued surge marking what International Energy Agency (IEA) now calls the Age of Electricity2. Yet while consumption accelerates, the grid is struggling to keep up. The US warns its network is already “too small” for the load coming from renewables, electric vehicles (EVs), and data-center growth3. Europe is staring at a €250 billion upgrade gap4. Across Africa and Asia, industrial expansion and rapid urbanization are stretching infrastructure to its limits5. Everywhere you look, the message is the same: demand is rising faster than the grid can evolve.

Global electricity demand is set to keep climbing through 2030, led by rapid growth from transport, data centers, and industry. Source: IEA (2025)

The Clock Is Ticking on Grid Delivery

With infrastructure investment accelerating, timelines across the power industry are tightening. For manufacturers of transformers, reactors, switchgear or control systems, delivering mission-critical equipment on time is critical. And success now depends on much more than sourcing components and securing freight capacity. Packaging, logistics, compliance, and installation support have become essential to operational success on every grid-modernization project.

Power equipment is far more fragile than it looks, and one handling or documentation error in transit can derail an entire project.

What’s so different about the transporting power grid equipment?

Unlike most industrial shipments, grid equipment is heavy, complex, and far more fragile than it looks. Transformers, switchgear, and reactors etc. must be fully tested, carefully dismantled, and packed to guard against shock, humidity, and even the slightest tilt as one handling mistake can surface later as a costly commissioning failure.

Add in multiple vendors, strict regulatory and international standards compliance, and limited visibility once crates leave the dock, and the risks stack up quickly.

When something goes wrong in transit i.e. a missed document, a vibration alert, the problem doesn’t show itself until the equipment is on site and crews are waiting.

That’s what makes shipping power equipment different: the stakes are higher, the room for error is smaller, and the consequences show up when they’re most disruptive.

Reducing Risk Starts Earlier Than You Think

To protect performance and scheduling, many OEMs are shifting to an integrated, end-to-end approach where one accountable partner manages packaging, documentation, tracking, and installation coordination from start to finish.

What end-to-end services typically include:

- Custom Crating and Packaging

Every piece of power equipment is different. Crates, skids, and frames are designed specifically for each unit’s size, weight, and transport method whether it’s going by truck, ship, or air.

Packing takes place directly at the manufacturing site because large, heavy equipment must be tested, carefully dismantled, and prepared for shipment.

Digital tools make it possible to monitor shipments in real time, tracking their location and condition along the way. If there’s a potential delay or issue, teams can react quickly before it turns into a costly problem.

Exporting high-value equipment means dealing with a lot of documentation, including packing lists, HS codes, certificates, and safety declarations. Having one team manage all of it helps ensure compliance with international standards and smooth customs clearance.

Once the shipment arrives, coordination continues with a detailed packing plan that tracks exactly where every component is stored. Knowing which box to open in which sequence is critical for smooth unpacking, and installation, minimizing downtime and keeping the project moving.

OEMs applying this model have seen clear benefits, including reduced damage-related delays and faster installation starts.

Where Delivery Performance Pays Off

End-to-end coordination doesn’t just simplify delivery, but it also protects project outcomes. With one accountable partner from packaging through installation, the number of handoffs drops dramatically, reducing the risk of errors and delays.

Engineered packaging and proper handling help prevent vibration, moisture, and impact damage, safeguarding equipment performance where it matters: at commissioning.

Real-time tracking and clean documentation bring visibility to every milestone, giving stakeholders confidence that timelines will hold. And with optimized materials and reusable packaging, sustainability goals can be met without compromising reliability or speed.

Conclusion

Grid-modernization projects depend on flawless delivery of highly engineered, high-value equipment. As complexity rises, so does the need for integrated support that protects performance at every step of the journey.

End-to-end packaging and logistics are not just an operational upgrade, but a direct investment in project success, customer satisfaction, and the reliability of the power systems that keep the world running.

We save resources in supply chains for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions for the Energy sector.

LEARN MORE

Solutions for the Energy Industry

Integrated Packaging and Logistics Solutions for the Energy Sector

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Global Engineering Network

250 engineering experts in more than 30 locations