Shipping rack dunnage

Nefab's shipping rack dunnage secures and protects parts on metal racks during transit. Reusable custom or standard solutions optimize logistics while reducing costs and environmental impact.

Nefab's shipping rack dunnage secures and protects parts on metal racks during transit. Reusable custom or standard solutions optimize logistics while reducing costs and environmental impact.

Nefab's rack dunnage ensures parts are securely held in place, preventing damage caused by motion, vibration, moisture, and debris during transit and handling.

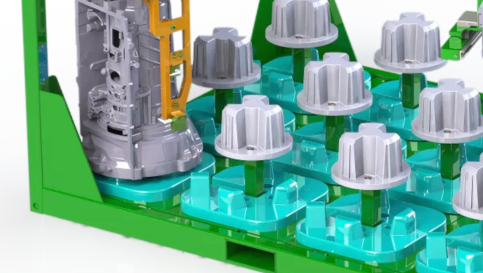

With a wide range of materials and manufacturing processes, Nefab offers both standard and fully customized solutions tailored to specific applications, from heavy-duty components to delicate parts.

Nefab's recyclable dunnage solutions are designed for reuse and to optimize space usage, thereby reducing logistics costs and environmental impact.

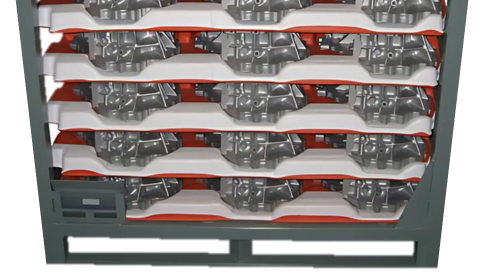

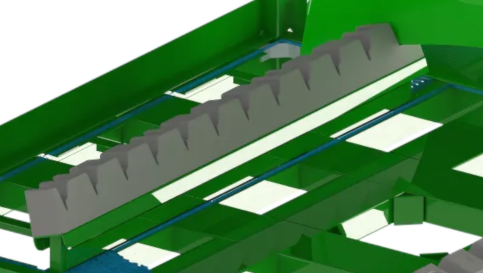

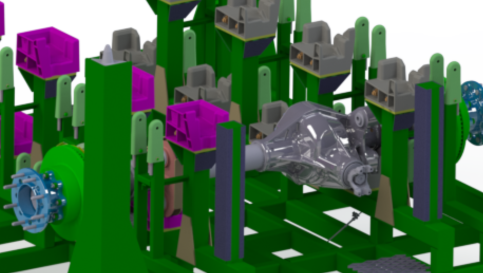

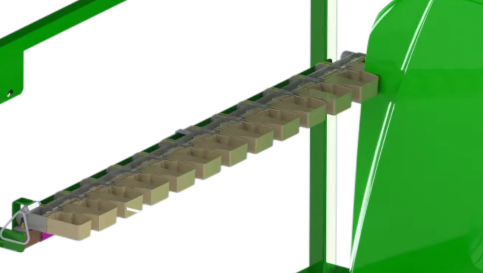

Shipping rack dunnage refers to specialized protective components designed to secure and protect parts on metal racks during transportation and storage. Shipping rack dunnage protects parts during transit by creating a barrier from the metal rack. It prevents movement, friction, and impact for safe transportation.

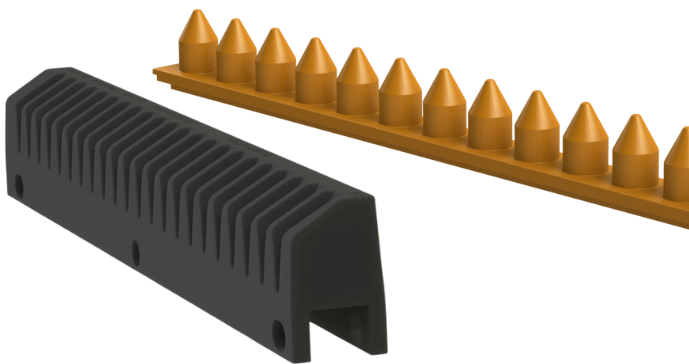

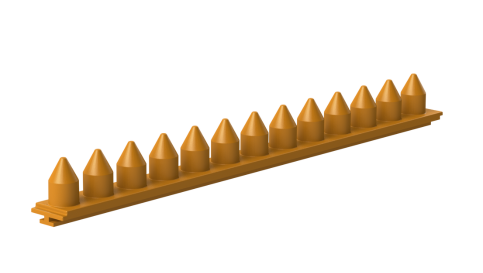

Dunnage can be made using a variety of materials and processes, including injection molding, cast polyurethane, foam polyurethane, and thermoforming. With the flexibility to combine multiple materials into a single solution, our extensive molding capabilities ensure you’ll find a cost-effective and adaptable option to meet your needs.

Nefab offers a full range of rack dunnage, from bar dunnage to base dunnage. Whether you need standard solutions from our catalog or custom designs, we’ll help you find the right shipping rack dunnage to protect your products.

Nefab’s shipping rack dunnage is designed to protect automotive parts during shipping and material handling, whether they are heavy components like engines and transmissions or delicate items like glass and body panels. Customizable for any fleet size or application, it safeguards parts against damage, moisture, static electricity, and contamination. Suitable for both shipping and interfacility handling, Nefab provides durable, reliable solutions to ensure your products arrive intact.

Complex and precise parts with tight tolerances can be produced efficiently in high volumes. Injection molding works with a wide range of materials.

Cost-effective base dunnage commonly used on hood and door racks to ensure proper separation during shipping.

Durable and ideal for heavy-duty, low-volume applications. It offers rapid tooling turnaround, easy prototyping, and various densities.

Nefab's catalog of standard rack dunnage with existing designs and molds, is a cost-effective and efficient choice for a wide range of applications. Contact Nefab today to request the catalog!

For the US market, we offer our standard plastic solutions in a B2B web shop. Effortless ordering, sustainable packaging solutions, and fast delivery – all in one place. Our product selection features standard solutions, including TPU buttons, brackets, and rack accessories.

Nefab provides both custom-engineered and standard rack dunnage solutions to meet diverse customer needs. Custom-engineered dunnage is designed and prototyped to fit unique product specifications, ensuring optimal protection and performance. For those seeking ready-made options, Nefab also offers a range of standard rack dunnage solutions.

Nefab saves environmental and financial resources by optimizing supply chains. We do so by innovating together with our customers to create smarter packaging and logistics solutions while always respecting people and ethical standards.

We provide complete packaging and logistics solutions that reduce total cost and environmental impact throughout the supply chain.

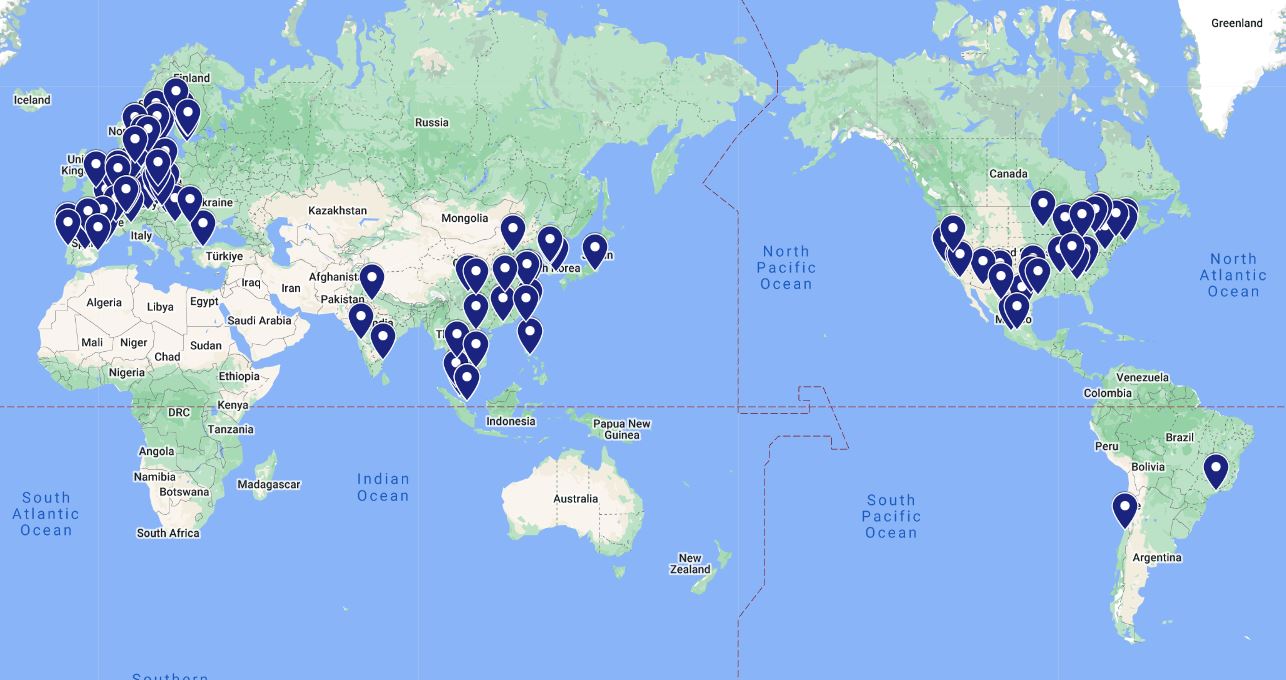

With over 250 engineers in 30 locations globally, we collaborate closely with customers to design, prototype, test, and deliver tailored packaging solutions.

Nefab's solutions reduce carbon footprints by 31%, on average, reflecting our commitment to sustainability within our operations and offerings.

With 75 years of experience and a presence in over 38 countries, we deliver global solutions with local support.

Are you looking for a complete packaging solution with inserts or inner fittings? Reach out to us today! Our team of experts in more than 39 countries is ready to collaborate, innovate, and deliver solutions tailored to your unique challenges. Contact your local sales representative for more information about Nefab packaging solutions and discover how they can enhance your logistics and sustainability efforts.

Corrosion protective films and other accessories

Custom inserts and inner fittings for product securement