關鍵要點

- 可再生能源投資與電網升級正加速推進;重型能源設備需具備耐用、輕量且便於遠端作業的包裝解決方案

- 安裝成功取決於同步抵達、清晰標示,以及專為長期儲存與惡劣環境設計的包裝。

- 數位化搭配追蹤與追溯功能可提升可視性,並能縮短週期時間及降低總物流成本

- 生命週期評估量化環境與財務節省效益,引導更優的包裝與物流選擇

重大變革正在進行,將重塑2030年的全球能源體系。清潔技術投資正急速增長,特別是在風能與太陽能領域,這要求物流與包裝技術必須針對偏遠惡劣環境進行重大創新。

Nefab全球能源部門總監彼得·比耶洛武克分享了產業應如何為增長做好準備。「全球正全面邁向清潔能源轉型,此趨勢勢不可擋。 這並非『是否會發生』的問題,而是『何時發生』的問題。」比耶洛武克表示。最新研究預測,能源市場的發電量將於2024年達到28.34兆度電,年均增長率達4.84%。請繼續關注我們探討能源領袖們必須如何在當下採取行動,以應對未來的挑戰。

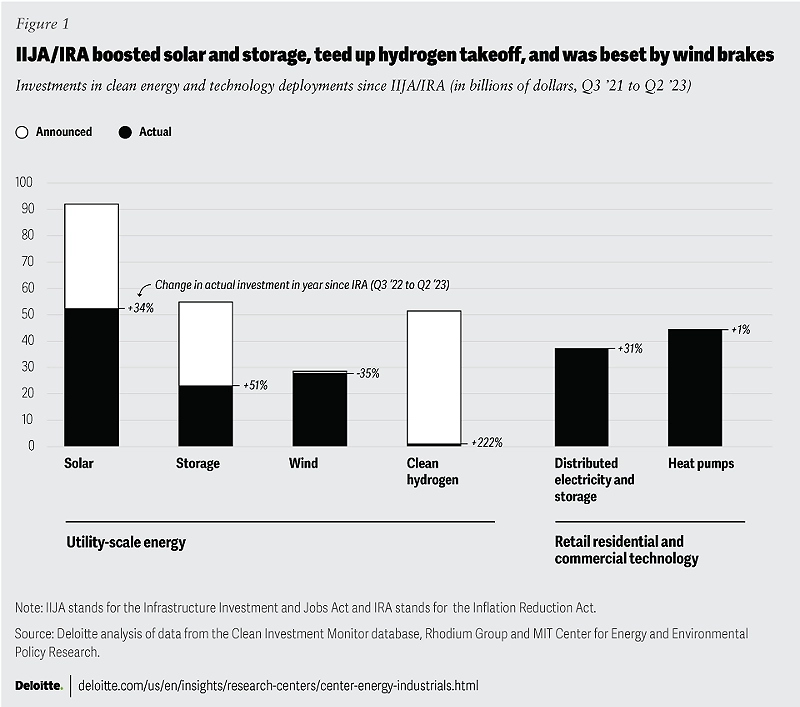

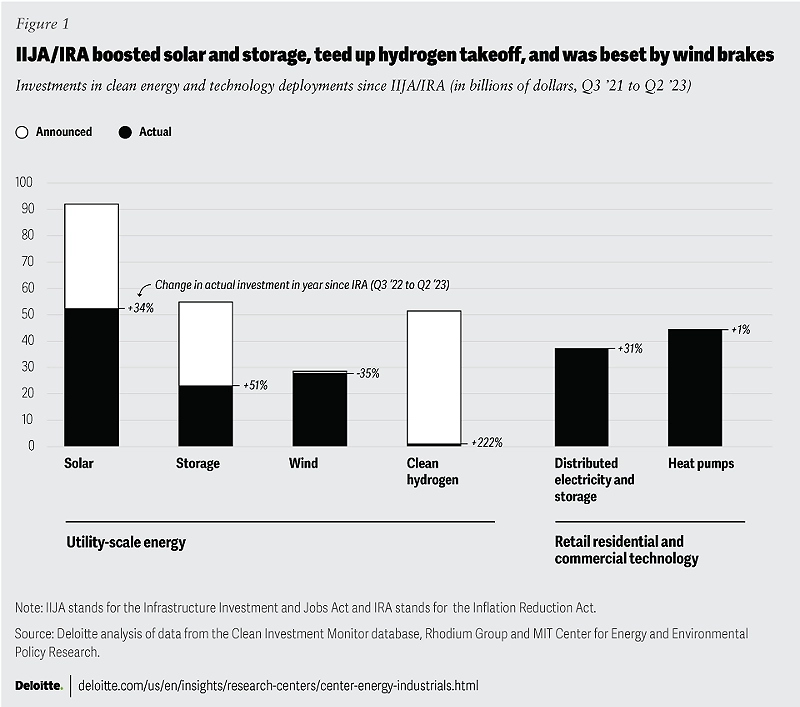

根據德勤報告指出,美國能源資訊署預期至2023年底,公用事業規模太陽能裝機容量將較2022年增長逾一倍,達到破紀錄的24吉瓦;風力發電容量則將增加8吉瓦。

全球可再生能源增長及其對物流的影響

配合COP28「能源系統擺脫化石燃料並於2050年實現淨零排放」的號召,全球推動再生能源的浪潮已迫在眉睫。 「人口增長、城市化與工業化正使全球能源需求急遽攀升。這種趨勢既存在於正從傳統能源轉型至綠色能源的已開發經濟體,也存在於能源需求持續增長的發展中經濟體。」貝耶洛武克如此闡述。

工業化國家轉向再生能源的典型案例當屬美國。美國能源資訊署宣布,截至2023年底,公用事業規模的太陽能裝機容量將較2022年翻倍,達到破紀錄的24吉瓦;風力發電容量則將增加8吉瓦。 另一方面,在印度等發展中國家,城市化進程正驅動能源轉型——當地中產階級規模急速擴張,預計2031年將佔總人口40%。為滿足日益增長的能源需求,電力網容量必須升級以應對未來更高負荷。 挑戰正始於此:在多變的天氣條件下,將重型發電機運送至偏遠地區,無論從物流或工程角度而言,都是艱鉅的考驗。

適用於全球任何偏遠地點的即裝即用包裝與服務

為確保安裝過程順暢,所有零件必須同時送達且狀態完好,需妥善包裝並標示清楚以便拆箱與搬運。部分貨物將等待數月直至安裝完成,因此包裝亦須確保能在多變氣候條件下長期儲存。 因此,運送珍貴能源貨物至目的地的最佳包裝方案,必須兼具耐用性、輕量化、易開啟與易搬運特性。此時安裝管理解決方案便發揮關鍵作用——其包含圖解包裝說明、裝載與現場佈局圖,以及即時短缺通報、事件警示與變更管理的連線服務。Bjelovuk闡述:「安裝管理解決方案不僅為客戶節省資本與資源,更能守護品牌聲譽。」

符合這些嚴苛要求的優質包裝範例,是採用木材或膠合板製成的無釘扁平包裝箱,適用於重型與中型產品。此類包裝不僅佔用極少儲存空間,且操作極為簡便。 憑藉採用合格木材來源製成的堅固輕量化設計,此類箱體特別適合用於長期儲存高價值、重型及易碎商品。根據產品規格,包裝應包含獨立內盒,確保所有零件清晰可見、取用便利,並以簡化安裝流程的順序排列。Bjelovuk補充道:「選用合格來源的木質包裝,既彰顯對環境的堅定承諾,亦體現對客戶的高度責任。」

數位化與互聯物流推動永續能源供應鏈

能源公司在安裝階段前應考量的另一重要議題,是投資數位服務以提升對珍貴物流的可視性與管控力。透過為每件包裝添加追蹤與追溯功能,能源公司得以監控運輸過程中的即時位置。Bjelovuk補充道:「這些數據不僅能提升效率,更能降低物流總成本,有時甚至可縮短高達65%的週期時間。」

運用生命週期評估衡量影響,以削減成本與二氧化碳當量

最後但同樣重要的是,要轉型全球能源供應鏈,必須運用生命週期分析(LCA)工具來追蹤並量化所有與包裝及物流相關的財務與環境數據。透過衡量各流程中的排放量、廢棄物、可回收性及不同材料類型,能源企業能清楚了解:若改用替代性包裝方案以確保運輸過程中的最佳條件,可節省多少資源。 「迄今我們已為各產業完成逾3000份生命週期分析。平均而言,無論在財務效益或永續發展層面,我們皆實現雙位數節省,完全符合能源產業的環保目標。」Bjelovuk補充道。

追蹤與追溯平台提供運輸過程中的即時位置資訊,不僅能提升物流效率,更能降低物流成本,有時甚至可將週期時間縮短高達65%。

今日應對明日的挑戰

能源領域確實正經歷一場重大轉型,全球正朝向更清潔、更永續的能源來源邁進,這將帶來諸多變革,包括將能源效率提升一倍。然而,透過結合永續性與可追溯性,一切皆有可能。憑藉合適的工具,能源企業能選擇最優化的包裝與物流解決方案,成功在世界各地即時追蹤資產,並大幅降低二氧化碳當量排放量。

Nefab如何在此方面支援能源產業?「2024年,我們將聚焦兩大方向:全球擴展服務版圖,確保所有客戶無論身處何地皆能獲得同等品質的支援;同時深化數位服務組合的開發。我們深信,末端優化正是能源產業亟需把握的關鍵拼圖——若未能善用此優勢,企業聲譽恐將蒙受損失。」Peter Bjelovuk如此總結道。

我們在供應鏈中節約資源,創造更美好明天

想瞭解更多資訊?

聯繫我們

聯絡我們 深入了解我們推動供應鏈前進的永續解決方案。

瞭解更多資訊

能源產業解決方案

能源領域的整合包裝與物流解決方案

GreenCalc

Nefab 自主研發的認證計算器,可精準量化並呈現我們的解決方案所帶來的財務效益與環境節約成效

永續解決方案

為永續供應鏈打造的工程包裝