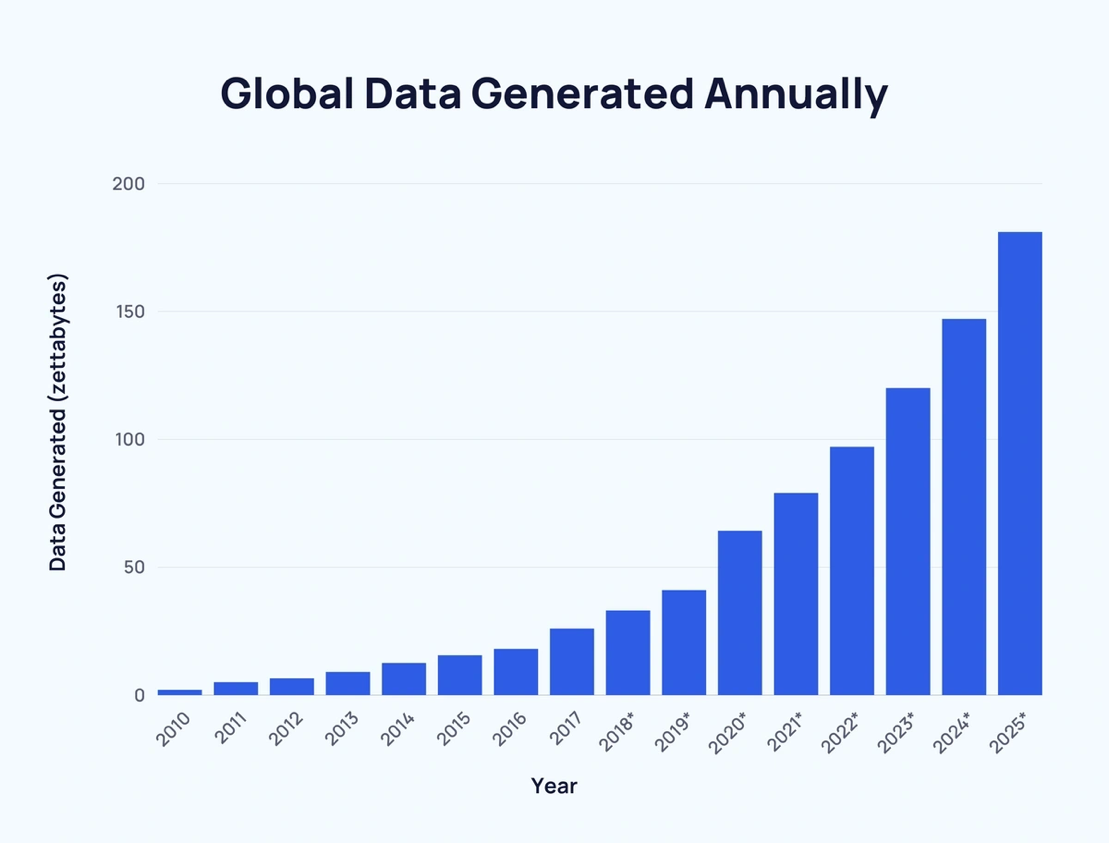

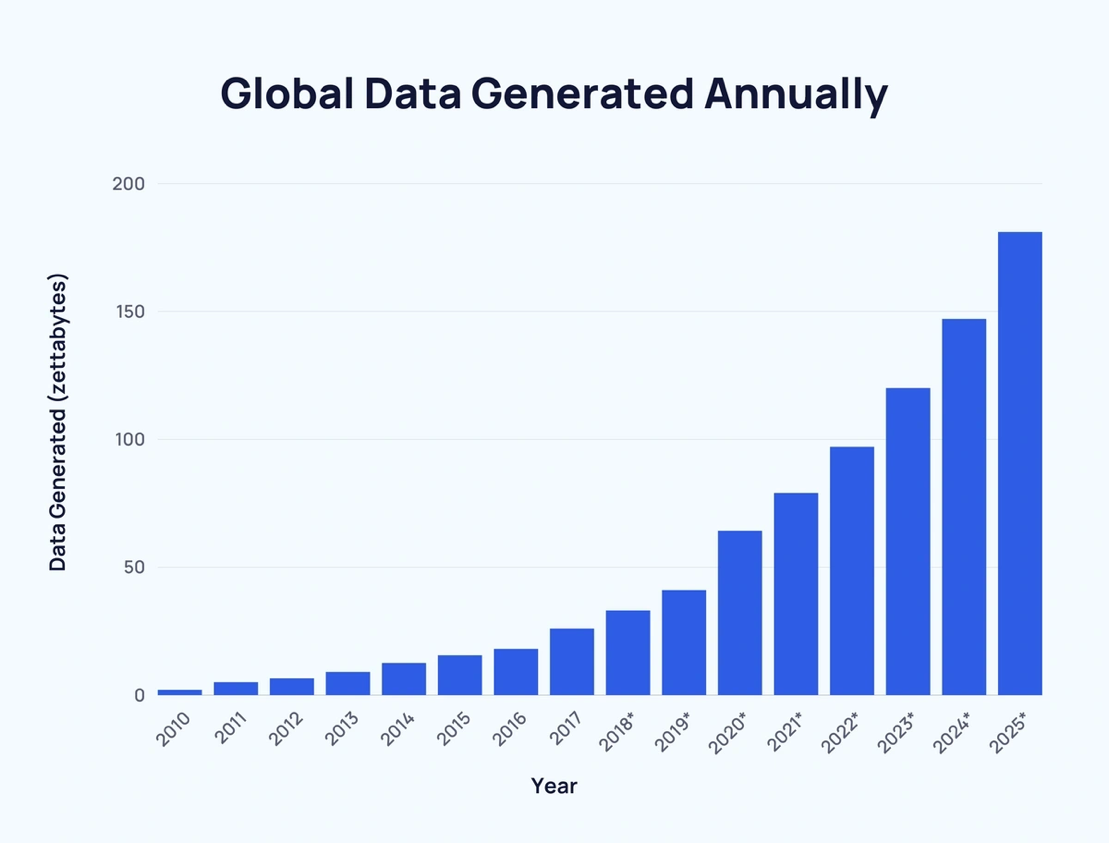

Only in 2023 alone, 120 zettabytes of data were created globally and this numbers are expected to surge to 181 zettabytes by the close of 20252. As the need for faster and more dependable communication services continues to rise, the significance of data center network technologies becomes apparent. These technologies play a crucial role in improving connectivity, scalability, and overall performance, thereby becoming essential in shaping the landscape of cloud computing and influencing the telecommunications industry.

Yet, this phenomenal growth wouldn't be achievable without a resilient global infrastructure supporting the industry's expansion. Surprisingly, the packaging and logistics services industry plays a crucial, albeit often overlooked, role in ensuring the seamless deployment of this infrastructure.

Innovation-Driven Future

The culture of continuous Innovation within the datacom and cloud industries is defined by dynamic relationships between ecosystem players driven by continues improvements through research & development. This extends to packaging and logistics providers, where agility and scalability through global coordination are paramount for swift market deployment. “We are talking about the industry that never sleeps. Short time-to-market is paramount. Once your products are ready, you need a one-stop-shop partner that is able to turn the concept around quickly and consequently design, sample, and test the packaging. All that with the ability to produce the same quality packaging across all geographies to ensure smooth deployment process. This is why the global reach and coordination capacities of your logistical partner are crucial.” Todd explained.

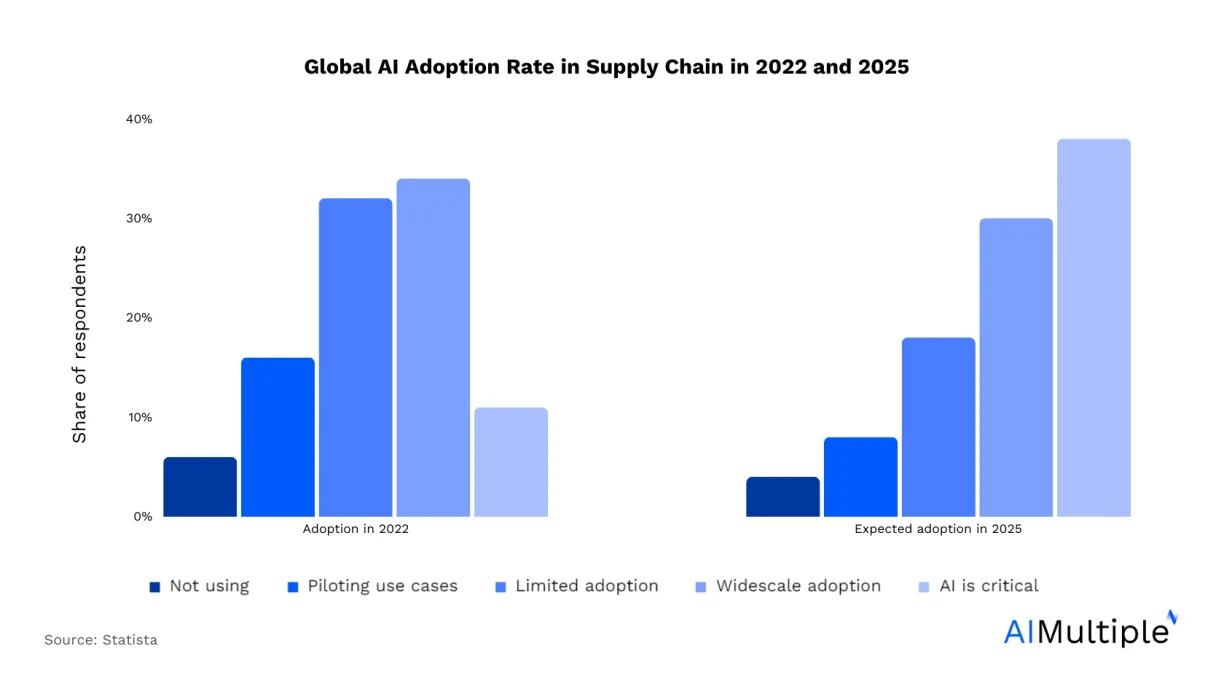

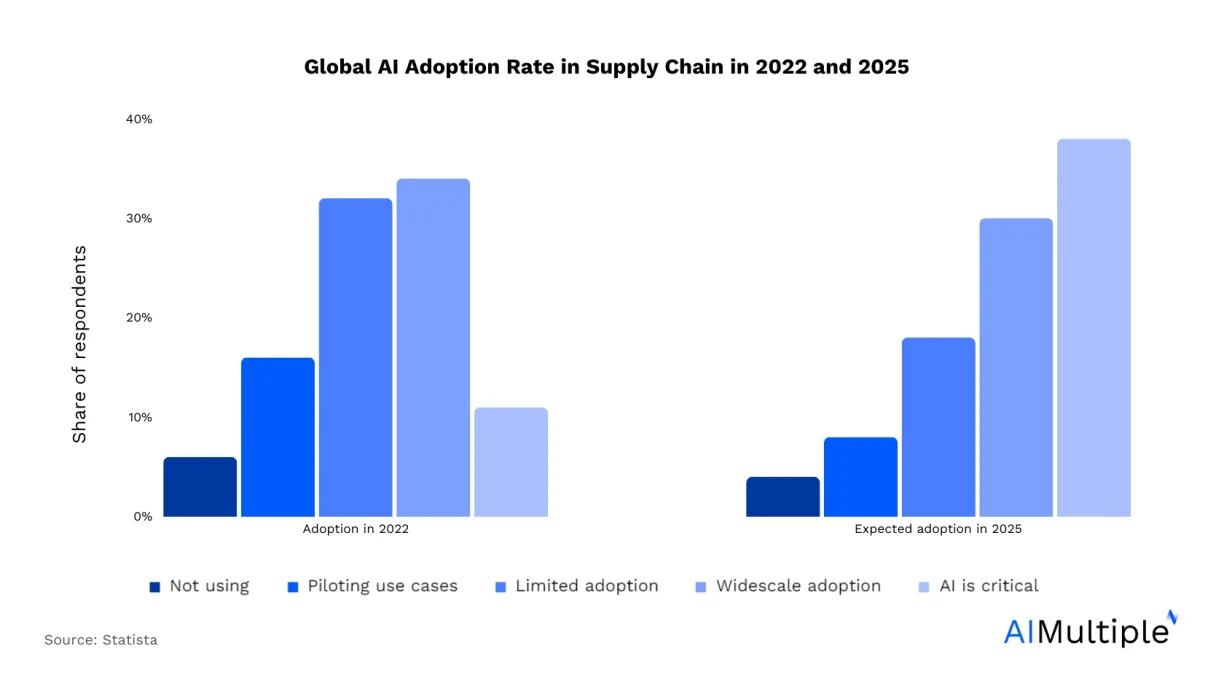

Big data and analytics are pivotal in informed decision-making and operational efficiency, marking a shift toward predictive analytics in 2024. With the raise of Artificial Intelligence (AI) and Functional Data Analysis (FDA), the way the packaging is designed, and logistical services provided is changing. The integration of AI, particularly Generative AI (GenAI), transforms traditional supply chain procedures, enhancing efficiency and adaptability. The integration of data analytics into supply chain management has gained significant ground, primarily attributed to the efforts of third-party logistics (3PL) providers.

The implementation of AI in supply chain is well underway and is expected to become a critical part of the industry by 2025

Sustainability Reporting Making an Impact

As the global awareness of climate change grows, industries face increasing pressure to disclose their environmental impact. While the US has historically relied on voluntary efforts for ESG (Environmental, Social, and Governance) matters, recent years have witnessed a significant shift. The U.S. Securities and Exchange Commission7, alongside federal agencies like the Federal Trade Commission and the Treasury, and state-level regulations, has introduced several initiatives and proposals, marking a rapid transformation in the regulatory landscape8. This contrasts with the European Union's specific directives9 and the United Kingdom's mandate10 by the Financial Conduct Authority for climate-related disclosures among listed companies.

There's a growing expectation for businesses to elevate their environmental standards, with a noticeable surge in proactivity across industries. Companies now focus on carbon neutrality strategies, reflecting a heightened emphasis on recyclability. “Sustainability principles are deeply ingrained in customer demands, particularly in packaging design, where the focus is on creating curbside-ready solutions that facilitate easy recycling post-use” Todd explained. New solutions can be validated through thorough Life Cycle Analysis (LCA) tools, which measure and identify areas of improvement in supply chains by considering factors like Global Warming Potential (GWP), water and energy consumption, types of packaging materials, transport modes, and logistics flows. The software quantifies the existing and proposed solutions' environmental and financial savings to help validate the choice.

Regionalization answering the demand for cost reduction

The persistent uncertainties regarding the economic outlook have been a consistent theme throughout the past years. Given the slowing global economic activity, tight financial conditions, and escalating geopolitical tensions, it is anticipated that much of the volatility will continue in the coming years. Under such circumstances, the companies are paying closer attention to the costs. Regionalization is a way to manage cots but also respond quickly to supply chain disruptions. Minimizing the transportation distance of goods not only results in cost savings but also contributes to a reduction in carbon emissions. “Global companies benefit from collaborating with partners with a worldwide presence to optimize their logistical flows through the entire product lifecycles. Sustainability and cost take out really go hand in hand”, stressed Todd.

為了更美好的明天,我們在供應鏈中節約資源。

想瞭解更多資訊?

聯繫我們

Contact us to learn more about our smart and sustainable solutions.

瞭解更多資訊

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials