挑戰:專業銷售點硬體的成本、效率與永續性

一家全球領先的軟體與科技公司,專門提供電子產品及專業服務,其分銷流程面臨重大挑戰。該公司產品透過海運全球發貨,需採用特殊包裝以確保運輸安全。然而其內部設計的托盤效率低下,每貨櫃僅能容納18件產品,且包裝無法堆疊。 所採用的材料——包括合板、松木及塑膠緩衝環——不僅面臨交期延長、最低訂購量高昂的問題,更在貨櫃價格飆升400%的時期推升了整體成本。

此外,疫情加劇了這些障礙,在推動永續發展目標的同時,更迫切需要採取有效的成本削減措施。

Nefab 的解決方案:輕量化泡棉托盤解決方案

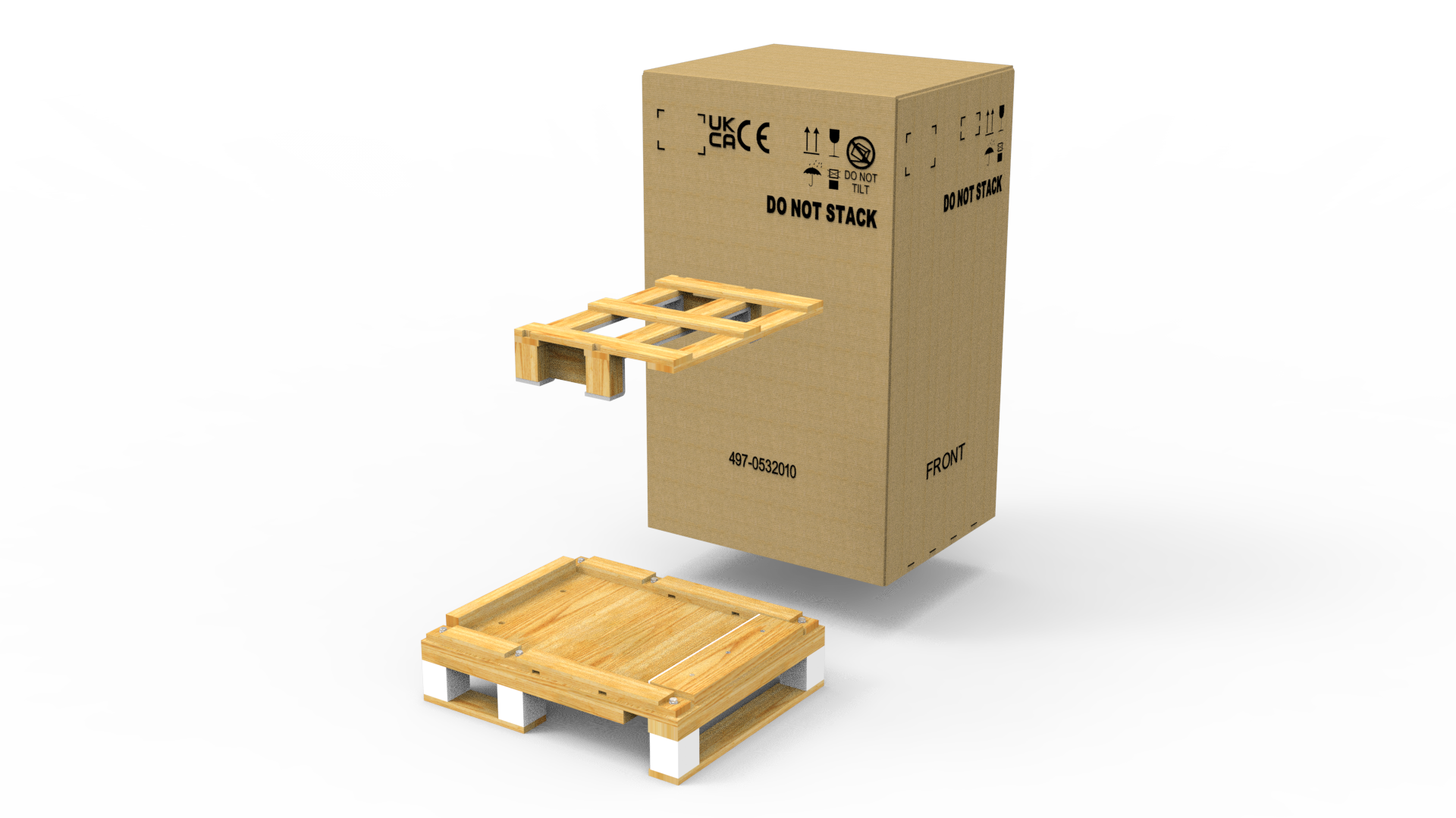

為解決這些問題,包裝團隊提出了一種創新且輕量的泡沫托盤解決方案。該方案採用兩種先進的聚乙烯泡沫托盤變體。重新設計包含以下關鍵改進:

- 強化貨櫃容量:單一貨櫃儲存量從18個單位提升至45個單位(其中一款型號),另一款型號則提升至53個單位。

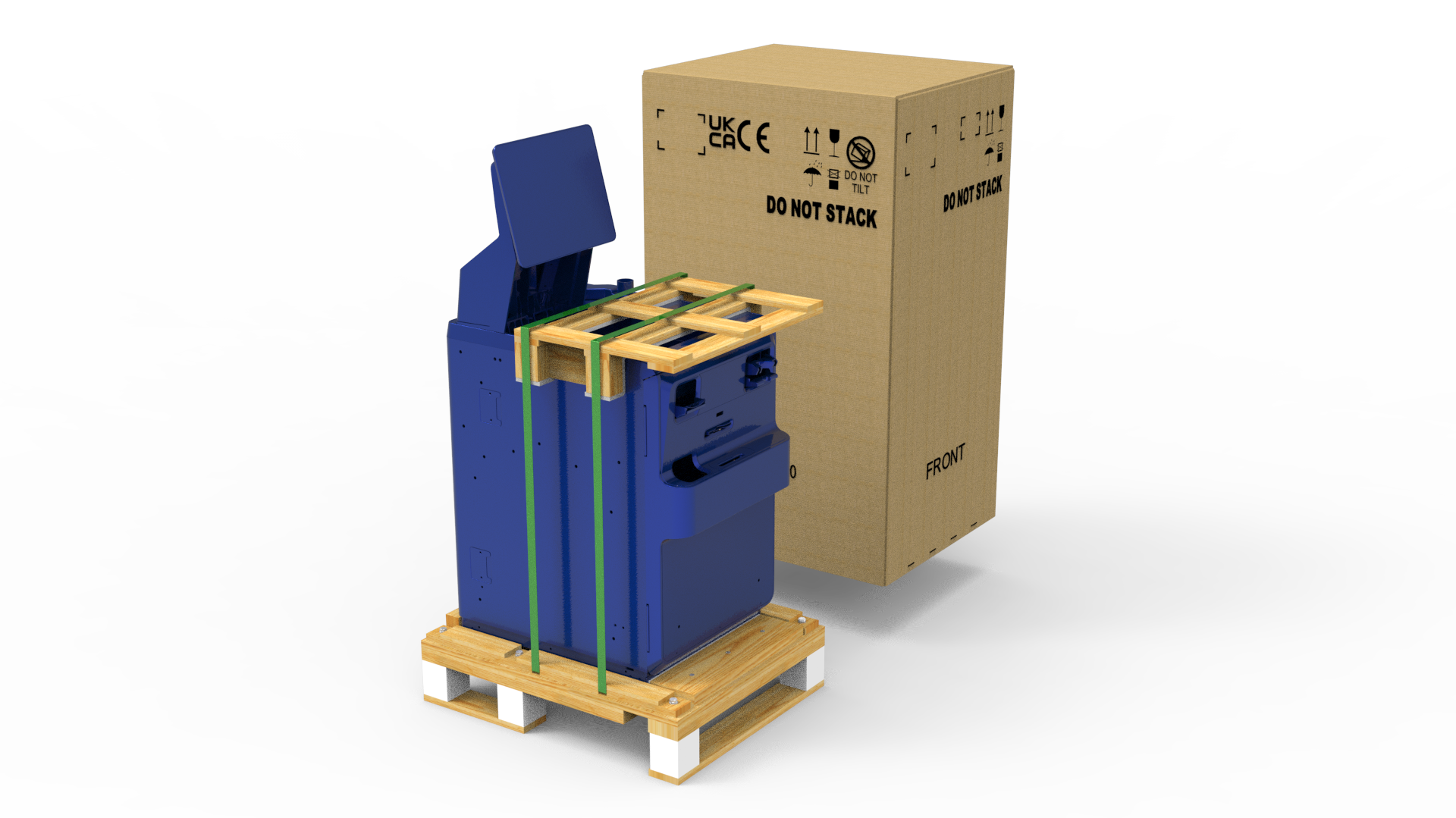

- 強化固定機制:新增膠合板角護板、泡棉緩衝墊、底托盤綁帶及頂部固定裝置,以保障設備於運輸過程中的安全。

- 更輕量化設計:降低整體設計重量,實現操作便利性與經濟高效的運輸效益。

- 優化生產流程:透過同時容納更多托盤,使輸送系統處理速度加快,每日產能從100台提升至150台。

該解決方案經過嚴格測試與驗證,滿足所有安全、耐用性及功能性要求,這些要素對於大規模實施至關重要。