挑戰:C型臂運輸的成本、安全與效率

客戶指出其現有包裝方案存在若干關鍵挑戰:

- 高成本:現有的包裝材料與設計大幅增加了整體運送成本。

- 產品安全:確保在運輸過程中為敏感的C型臂設備提供防震保護,是當前亟待解決的關鍵課題。

- 安裝與拆卸的便利性:醫院內運送與拆封C型臂設備相當困難。狹窄的走廊、缺乏裝卸平台,以及無需工具即可完成設置的需求,使整個流程變得繁瑣。

客戶需要一套系統,能在艱困環境中降低成本、提供卓越防護並簡化交付流程。

Nefab解決方案:創新且永續的無釘解決方案與斜坡

供應商創新推出了一套全面解決方案,針對客戶的每個痛點提供對應對策:

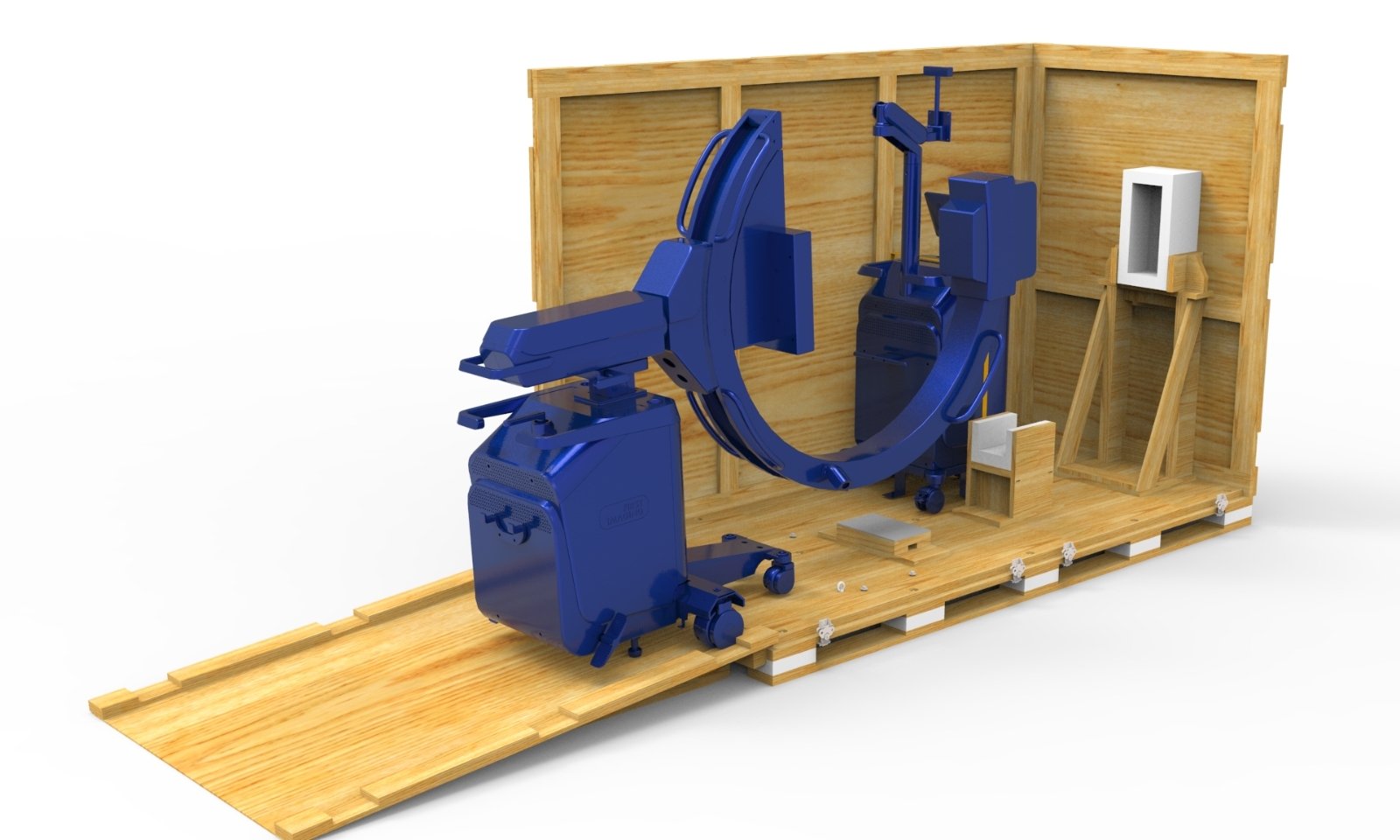

- 無釘解決方案 + 斜坡

無釘設計使組裝與拆卸無需工具即可輕鬆完成,完美契合醫院的物流挑戰。同時增設斜坡以簡化運輸流程,使設備能高效通過狹窄走廊。

- 輕量化材料

透過採用減少20%空包裝重量的設計,在維持耐用性與保護標準的前提下,大幅降低了整體運輸成本。

- 強化防震保護

採用EPE緩衝托盤取代先前使用的滑板托盤,不僅以更低的成本實現卓越的緩衝效果,更有效降低了運輸過程中的衝擊力。

- 內部木製裝潢

內部木質固定裝置的加裝有效固定了C型臂,確保其在運輸過程中保持穩定且受到保護。

此整體性方法確保了客戶的特定需求獲得滿足,同時為其物流流程增添了顯著價值。