挑戰:保護主板在運輸過程中的安全

該公司針對高端科技產品所使用的巨型精密主機板,其現有包裝方案面臨重大挑戰。先前方案採用瓦楞紙箱搭配EPE與EVA泡棉強化結構,但存在以下關鍵問題:

- 可回收性限制:部分材料經黏合處理,導致無法進行妥善回收。

- 運輸損壞:先前包裝設計未能充分保護產品,導致運輸過程中發生高昂的損壞損失。

- 環境影響:非優化設計導致材料浪費增加及碳足跡擴大。

該組織需要一套精簡的解決方案,以強化產品保護、提升可回收性並降低成本。

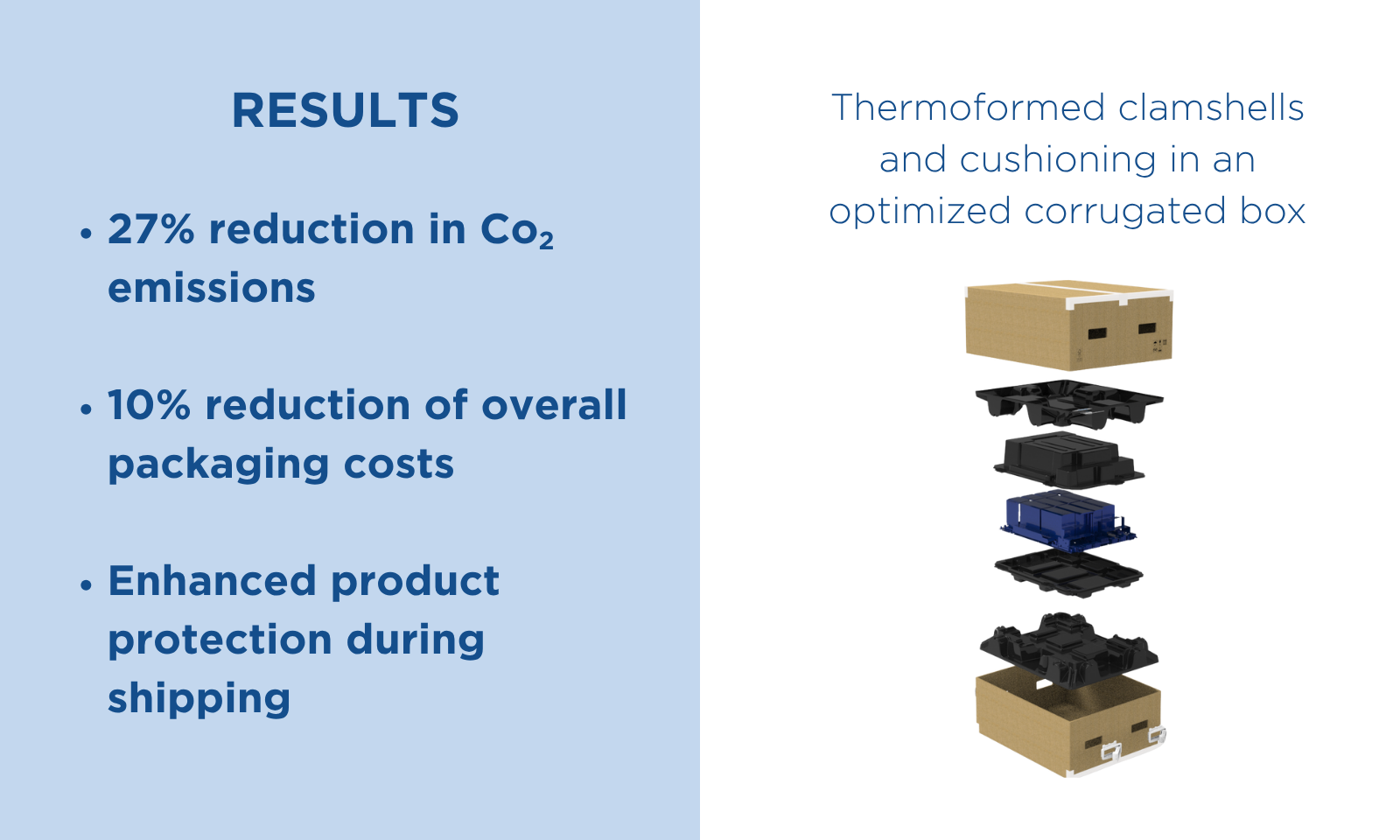

Nefab解決方案:採用HDPE熱成型反射元件的混合包裝創新

該包裝解決方案供應商推出了一款突破性的混合設計,其性能顯著超越前代產品。該解決方案的核心要素包括:

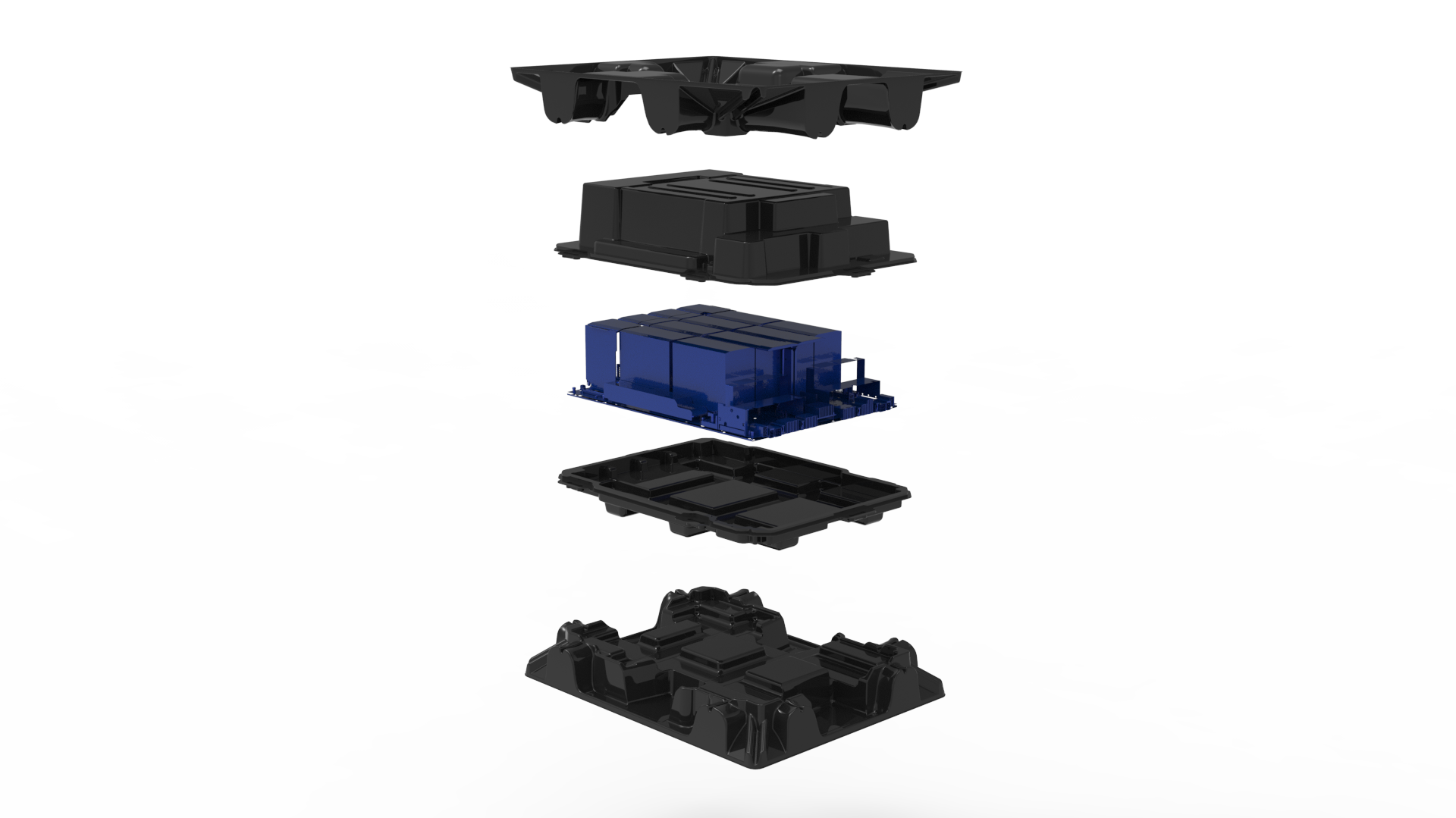

- HDPE熱成型反射元件:此設計採用雙殼結構牢固固定主機板,並輔以反射緩衝元件提供全面防護。這些元件採用100%再生HDPE製成,且可完全回收再利用。

- 優化瓦楞紙箱:採用更優化的外箱結構設計,在提升強度同時減少材料用量。

- 防靜電低密度聚乙烯袋:為進一步保護敏感電子元件,設計中特別採用了防靜電保護袋。

這項創新解決方案不僅降低了環境衝擊,更提升了產品在運輸過程中的安全性。