挑戰:端到端無塑化物

現行聚乙烯泡棉產生大量塑膠廢棄物,且與紙張回收流程不相容,導致無法達成客戶的循環材料目標。此外,包裝不僅需在運輸過程中提供可靠保護,更須貫徹至最終安裝地點,同時不得增加處理或安裝流程的複雜性。

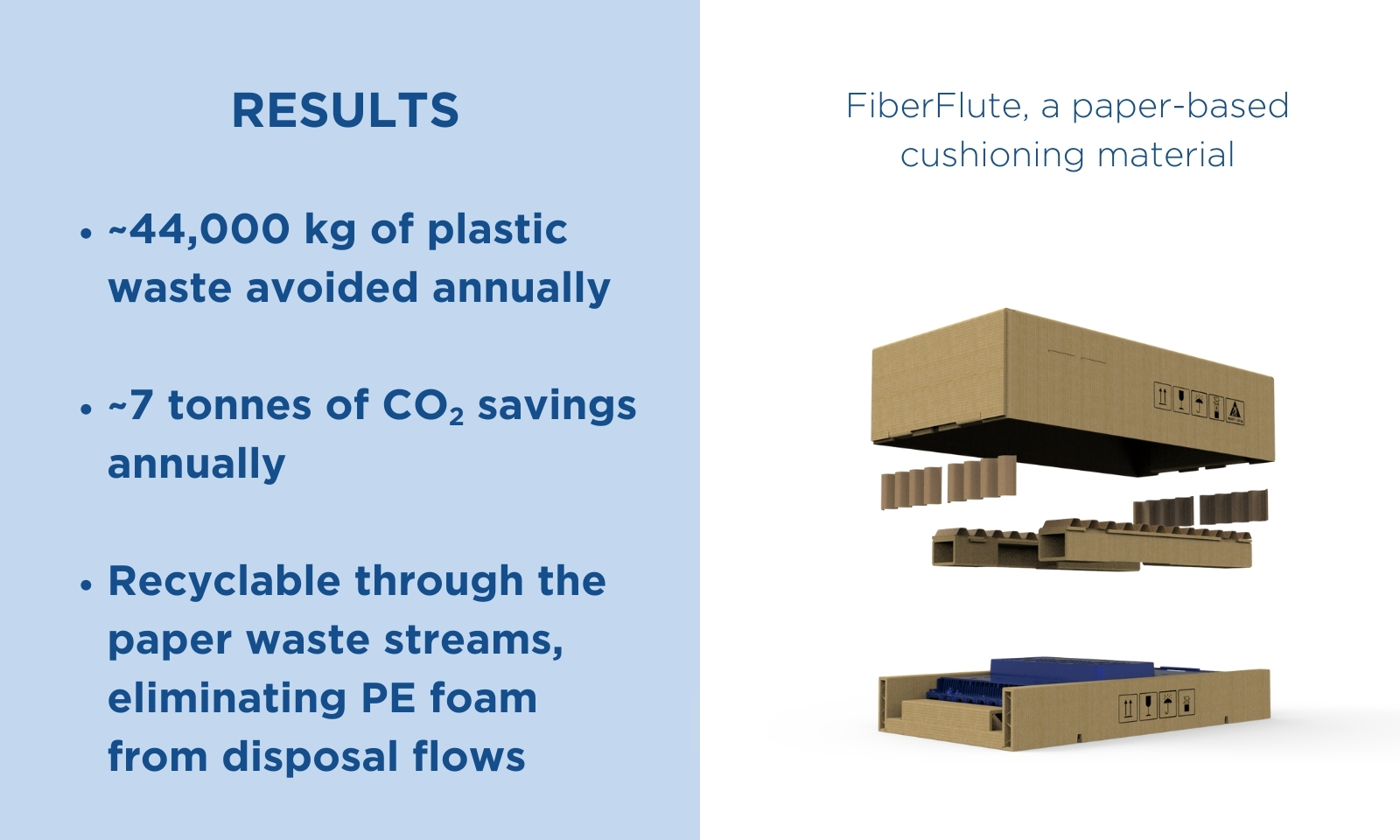

Nefab 的解決方案:FiberFlute

Nefab推出FiberFlute紙基緩衝材料,旨在取代塑料泡沫。嚴謹的技術測試證實了FiberFlute的強度與抗衝擊性,確認其能在供應鏈運輸與搬運過程中有效保護產品。此包裝設計可伴隨產品直至最終安裝階段,確保全程防護;由於FiberFlute採用紙基材質,可透過現有紙類廢棄物回收系統進行循環利用,從而將聚乙烯泡沫排除於廢棄物處理流程之外。