Plastic-Free Protective Packaging for 5G RF Modules

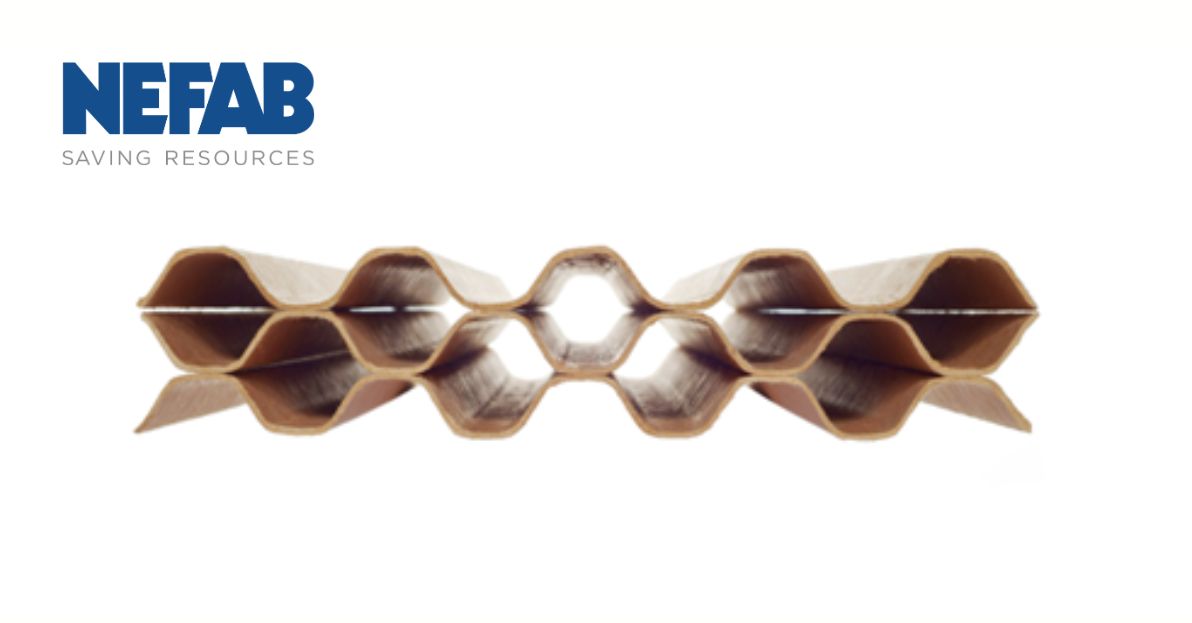

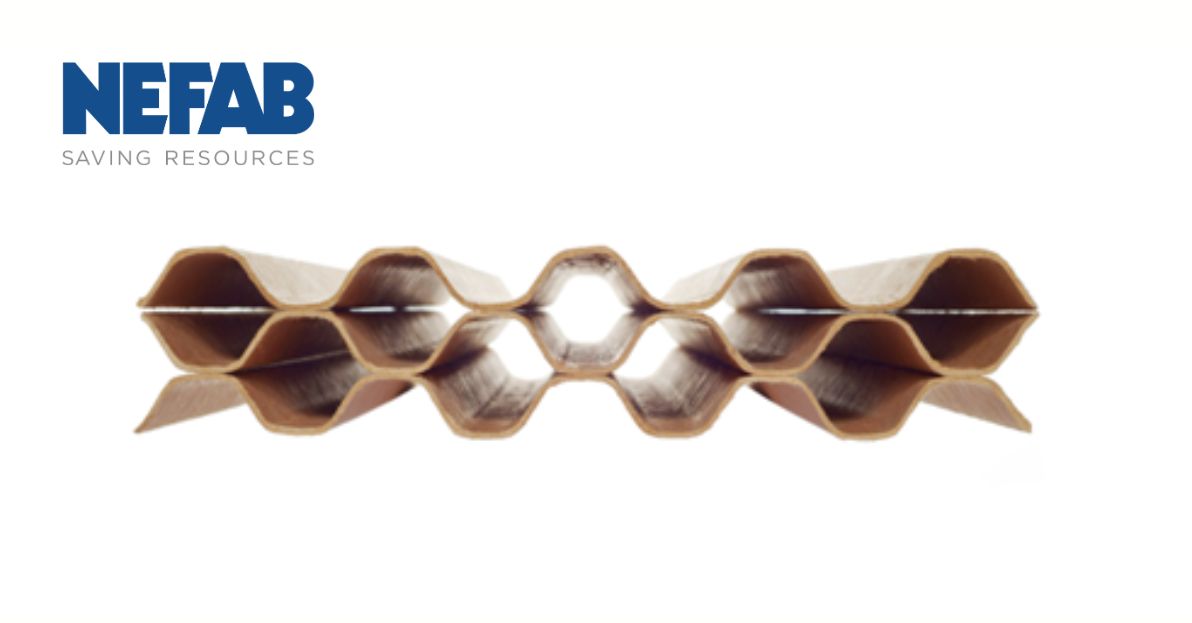

The new packaging system features FiberFlute, a paper-based cushioning material engineered to replace plastic foam. Rigorous technical testing confirms FiberFlute’s proven strength, impact resistance, and ability to safeguard products during transport and handling throughout the supply chain.

Key Benefits of the FiberFlute Solution

Significant Plastic Waste Reduction: By replacing polyethylene (PE) foam with FiberFlute, the packaging eliminates plastic and can be recycled through established paper waste streams. This leads to the reduction of approximately 44,000 kg of plastic waste annually.

Lowered Carbon Emissions: The new design reduces CO₂ emissions by 7 tons per year by decreasing the Packaging Carbon Footprint per shipped unit.

Optimized Last Mile Protection: The packaging is engineered to remain with the product until final installation, providing comprehensive protection all the way to the installation site.

Advancing Resource Efficiency Through Partnership

The packaging system incorporating FiberFlute was developed by Nefab in close collaboration with Nokia’s engineering, sustainability, and supply chain teams. By aligning technical requirements with environmental targets, both companies have achieved a packaging system that supports operational efficiency while advancing sustainability objectives.

Recognition and Ongoing Commitment

The FiberFlute project has been recognized as a finalist for the Nokia Diamond Award 2025 in the Sustainability category. The Sustainability Award highlights suppliers who advance Nokia’s environmental goals through measurable contributions to sustainability, environmental performance, and demonstrated innovation.

Nefab remains committed to further innovation in fiber-based packaging, helping partners to reduce environmental impact and to enhance resource efficiency.

Ready to Take the Next Step

Try our new packaging system featuring FiberFlute, a paper-based cushioning material engineered to replace plastic foam. Rigorous technical testing confirms FiberFlute’s proven strength, impact resistance, and ability to safeguard products during transport and handling throughout the supply chain.

Talk to Our Experts

Discover Our Solutions for the Telecom Industry

Explore more of our smart and sustainable solutions for the Telecom sector and see how we help customers achieve their financial and environmental goals.

Explore the Telecom Solutions Page

Discover comprehensive packaging and logistics solutions designed specifically for the telecom industry.

Related Telecom Customer Cases

Telecom Industry Insights

- How Reverse Logistics and Smart Packaging Power Telecom’s Infrastructure Upgrades: Discover how returnable packaging and digital tracking streamline upgrades, extend equipment life, and support circular supply chains during 5G and 6G rollouts.

- Why Abrasive Protection is Critical for Telecom Hardware in a 5G and 6G World: Learn why protecting sensitive components from scratches and micro-damage is vital for network reliability, and how new fiber-based solutions reduce plastic use while enhancing equipment safety.

- Designing Out Waste in the Telecom Industry Supply Chain: Learn how fiber-based, recyclable, and biodegradable packaging is replacing virgin plastics, letting telecom companies minimize waste and protect equipment even in remote environments.

- Why Telecom Hardware Manufacturers Should Embrace Contract Logistics for Better Inventory Management: Discover how contract logistics enhances inventory visibility, streamlines operations, and elevates delivery reliability to meet the demands of fast-moving telecom supply chains.

- Transforming Telecom Supply Chains: The Power of Innovation and Collaboration.: Explore how industry partnerships, end-to-end supply chain visibility, and sustainable materials are driving the future of telecom supply chain transformation.

Additional Resources