The Challenge:

The installation site faced inconsistent and fragmented deliveries: radio units arrived from the manufacturer while accessories and installation materials came separately from multiple thirdparty providers. This led to frequent late or partial arrivals, mismatched components, and time consuming kitting and warehousing on site. The lack of standardized packaging reduced visibility and control over site kits, increased labor and handling costs, and limited container utilization resulting in higher freight costs, longer lead times, and greater risk of delays and rework.

Nefab’s Solution:

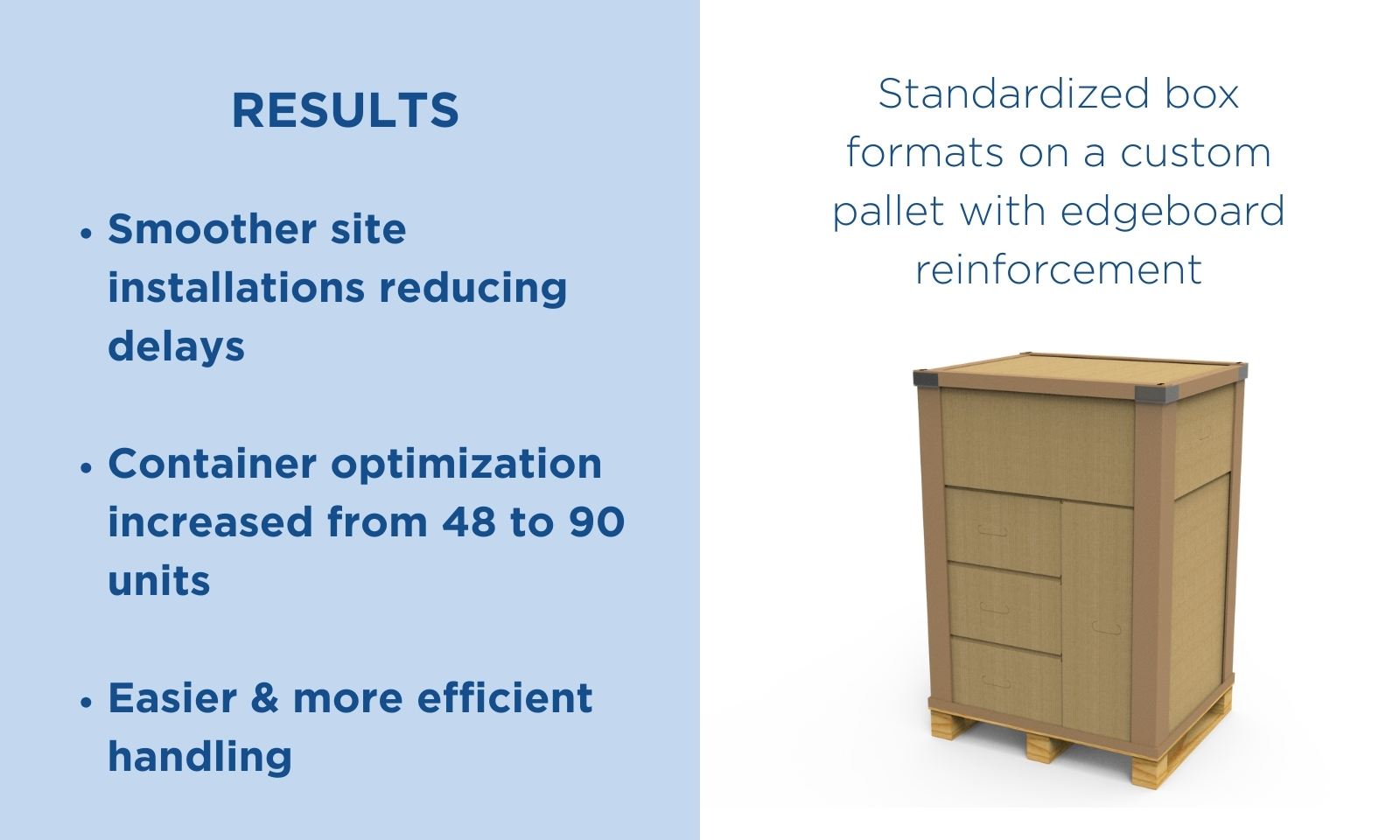

Nefab implemented a packaging solution to consolidate materials from the manufacturer and multiple third party providers into a single, stackable corrugated kit — a “one site, one box” approach. The design used two standardized box formats on a custom pallet with edgeboard reinforcement to protect components and enable safe stacking for container transport. This allowed all items required for a site installation to be packed together, shipped as one unit, and unpacked at site without additional kitting, improving visibility, protection, and container utilization while reducing handling, transit damage, and freight cost per unit.

The Results: Enhanced Operational Flow

Enhanced operational flow through a “one site, one box” packaging strategy, delivering smoother site installations and mitigating costly schedule and rework delays. Key outcomes included:

- Container optimization increased from 48 to 90 units.

- Packaging standardized for easier and more efficient handling

Redy to Take the Next Step

Our optimized packaging strategy consolidates shipments to improve visibility, reduce handling costs, and improve container utilization. Discover how a unified approach can transform your supply chain efficiency.

Talk to Our Experts

Discover Our Solutions for the Telecom Industry

Explore more of our smart and sustainable solutions for the Telecom sector and see how we help customers achieve their financial and environmental goals.

Explore the Telecom Solutions Page

Discover comprehensive packaging and logistics solutions designed specifically for the telecom industry.

Related Telecom Customer Cases

Telecom Industry Insights

- How Reverse Logistics and Smart Packaging Power Telecom’s Infrastructure Upgrades: Discover how returnable packaging and digital tracking streamline upgrades, extend equipment life, and support circular supply chains during 5G and 6G rollouts.

- Why Abrasive Protection is Critical for Telecom Hardware in a 5G and 6G World: Learn why protecting sensitive components from scratches and micro-damage is vital for network reliability, and how new fiber-based solutions reduce plastic use while enhancing equipment safety.

- Designing Out Waste in the Telecom Industry Supply Chain: Learn how fiber-based, recyclable, and biodegradable packaging is replacing virgin plastics, letting telecom companies minimize waste and protect equipment even in remote environments.

- Why Telecom Hardware Manufacturers Should Embrace Contract Logistics for Better Inventory Management: Discover how contract logistics enhances inventory visibility, streamlines operations, and elevates delivery reliability to meet the demands of fast-moving telecom supply chains.

- Transforming Telecom Supply Chains: The Power of Innovation and Collaboration.: Explore how industry partnerships, end-to-end supply chain visibility, and sustainable materials are driving the future of telecom supply chain transformation.

Additional Resources