- News & Insights

- 2025

- Packaging Innovation for Forklift Steering Module

- Customer Cases

- Industries

Packaging Innovation for Forklift Steering Module

The customer, a long-standing electronics contract manufacturer, required a significant shift in their approach to packaging solutions. With over four decades of experience in electronics manufacturing, the customer faced increasing demands for environmentally friendly solutions from their own clients.

The Challenge: A Sustainable Solution for Forklift Steering Modules

The customer needed fully recyclable packaging for a new forklift steering module. This module presented several challenges due to its dense and heavy nature, as well as the high number of units packed into each shipment. The project was further complicated by the demands of long-term sea transit from Europe to North America. Adding to the complexity was the customer’s client, a major automotive company, whose stringent sustainability requirements included eliminating foam and addressing entire packaging flow elements, such as pallets and stretch films.

Nefab's Solution: Innovative Packaging Solutions for Complex Logistics

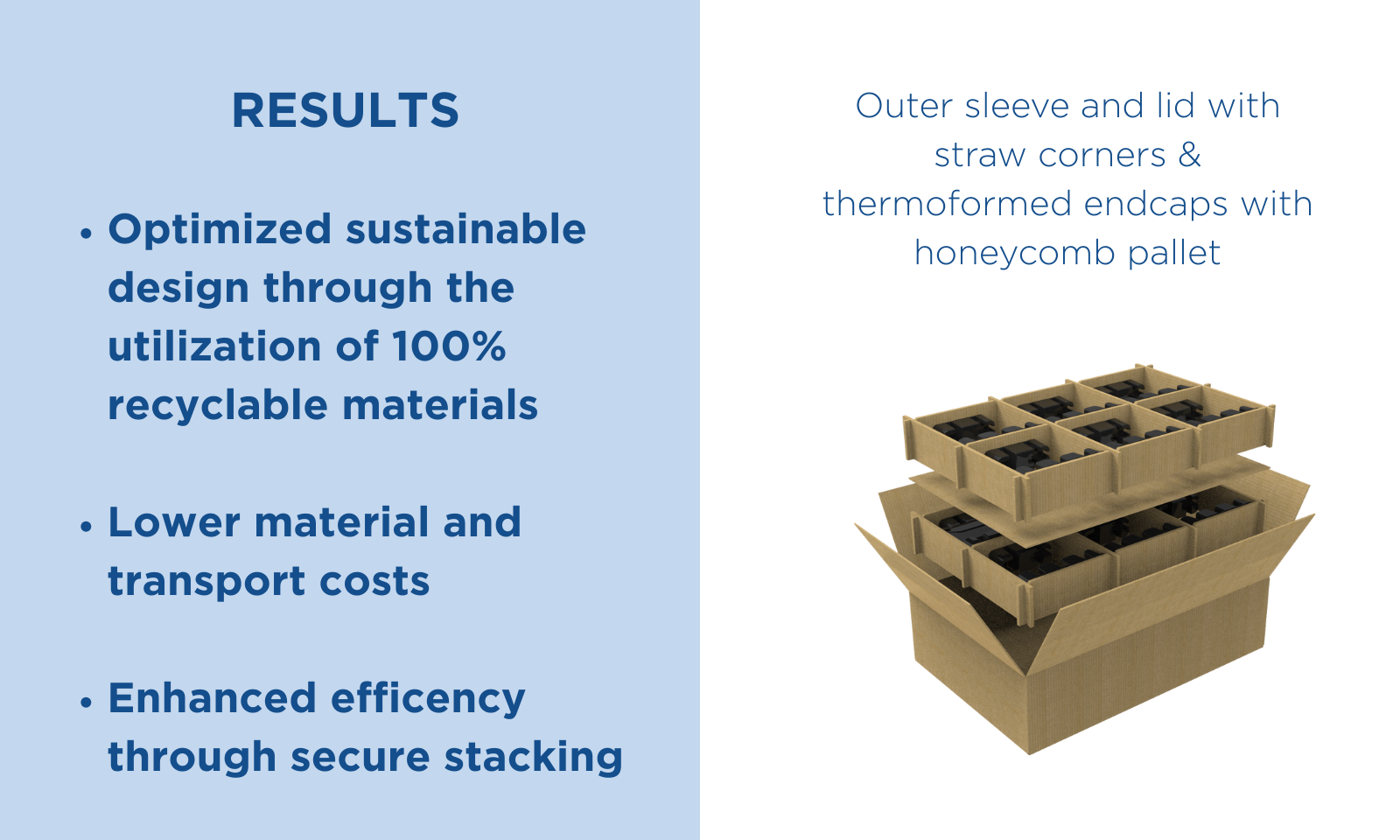

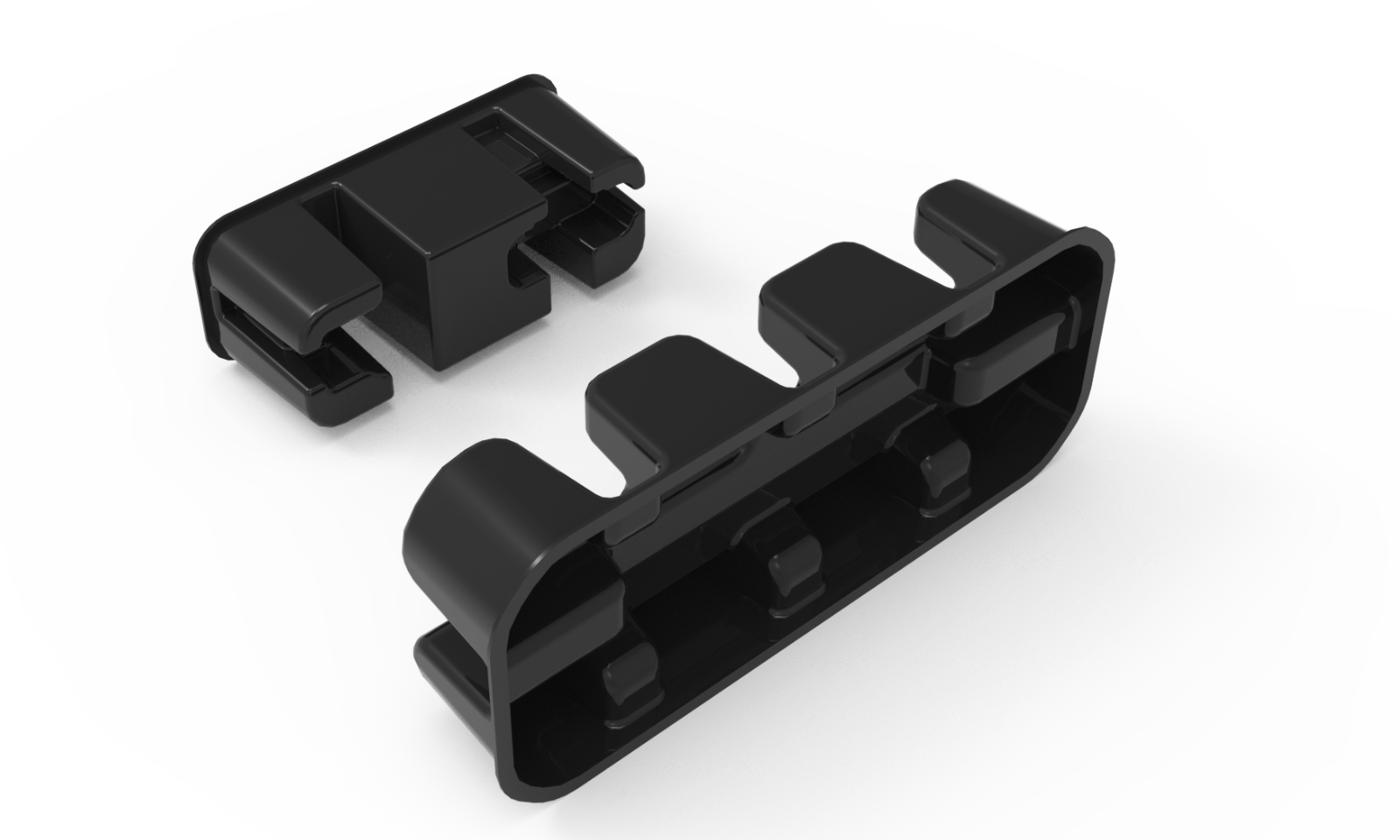

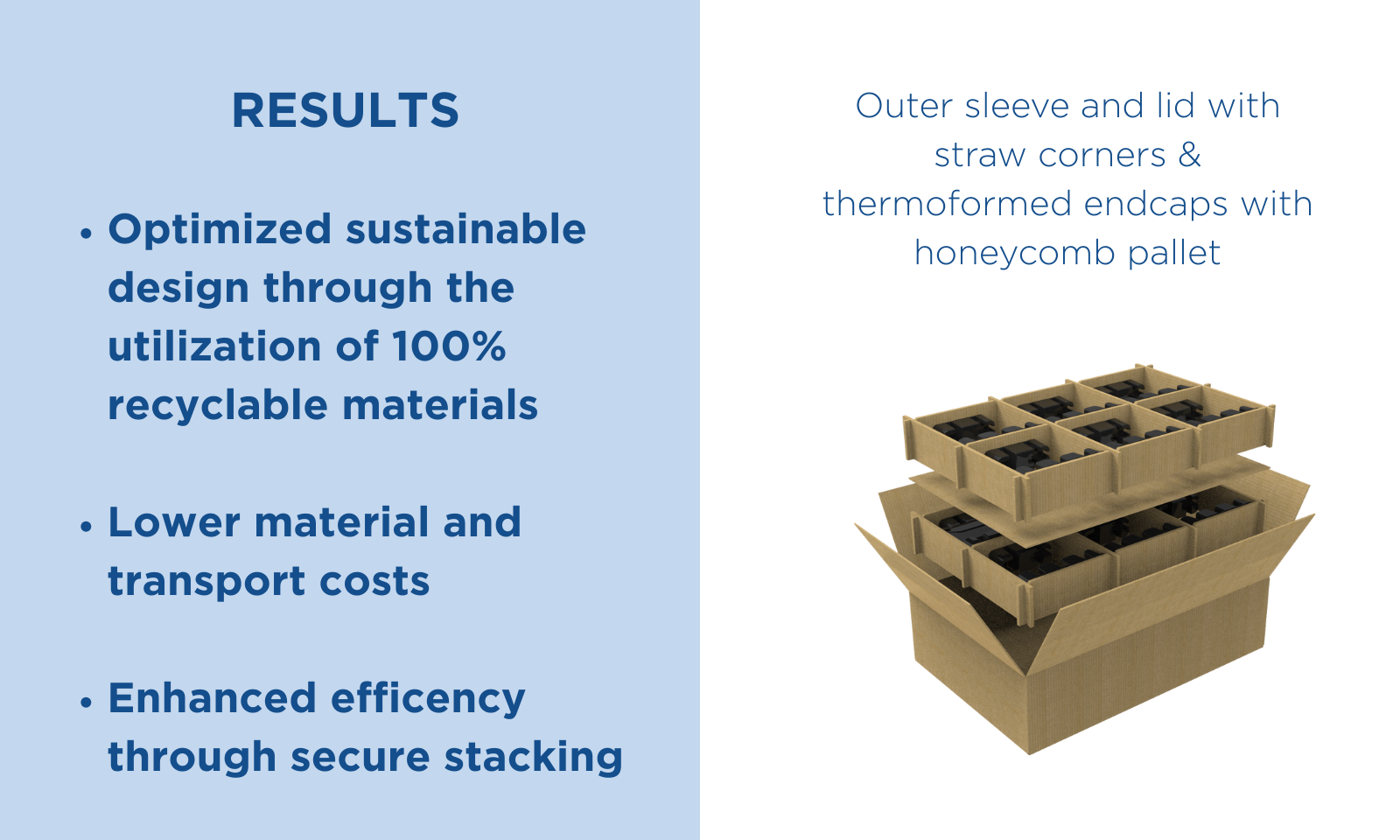

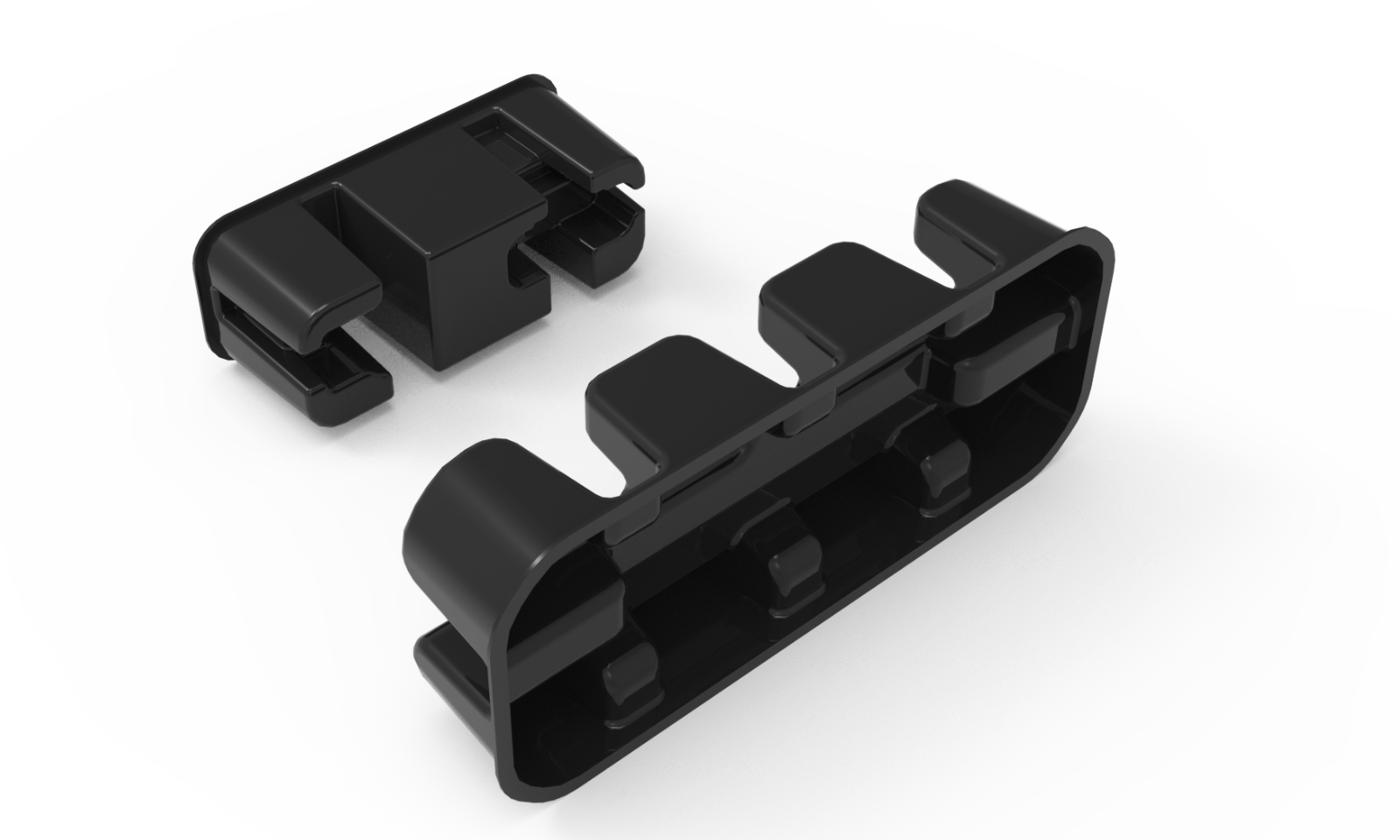

Nefab proposed a holistic solution composed of thermoformed end caps together with an inner corrugated grate. This was packed in a corrugated box with an external sleeve and lid, reinforced by straw corners. Finally, the team proposed utilizing a honeycomb pallet to replace traditional wooden pallets. Overall, we created a packaging solution that was fully compliant with sustainability requirements outlined by both our customer and their client.

This comprehensive redesign not only met the required sustainability standards but also optimized the durability of packaging for long overseas shipping. The innovative use of straw corners provided enhanced support for 1+1 stacking in transit, ensuring safe delivery of the modules.

Thermoformed endcaps

Thermoformed endcaps

This comprehensive redesign not only met the required sustainability standards but also optimized the durability of packaging for long overseas shipping.

Results: Long-Term Eco-Friendly Packaging Solution

The customer was thoroughly impressed with the solution’s efficiency and sustainability impact. The seamless adaptability and quick turnaround demonstrated by Nefab allowed implementation without delays, earning approval from their client. Benefits of this solution included:

- Sustainability Requirements Fulfilled: The fully recyclable design not only met the immediate requirements but also reinforced a broader commitment to sustainable practices.

- Material and Transport Costs Lowered: Shifting towards recyclable materials in packaging and lighter materials helped to reduce material and transportation costs.

- Enhanced Efficiency: The straw-reinforced structure facilitated secure stacking during transit, maximizing shipment capacity.

Take the Next Step

Switch to high-performance, recyclable fiber packaging today. Our fully recyclable design lowered both material and transport costs, which enhancing efficiency. We can help you achieve similar results.

Talk to Our Experts

Learn More About our Solutions for Manufacturing Excellence

Explore more of our smart and sustainable solutions for customers in different industries, and see how we help customers achieve their financial and environmental goals.

Explore the Others Industries Solution Page

Discover comprehensive packaging and logistics solutions designed specifically for a number of different industries.

Related Industry Customer Cases

- Streamlining Packaging for Heat Exchangers: Discover how this solution eliminated operational inefficiencies, including inventory pulling errors and unnecessary third-party involvement, leading to a simpler and more cost-effective logistics flow.

- Mono-Material Packaging for Carbon Brake Discs: See how we engineered a fully corrugated, mono-material solution, cutting our customer's CO2 emissions by 36% as well as improving storage, transit, and recycling.

Additional Resources