The Challenge: End-to-End Plastic Free

The incumbent PE foam generated large volumes of plastic waste and was incompatible with paper recycling streams, preventing alignment with the customer's circularmaterials targets. In addition, the packaging needed to provide reliable protection not only during transport but all the way to the final installation site, without adding complexity to handling or installation processes.

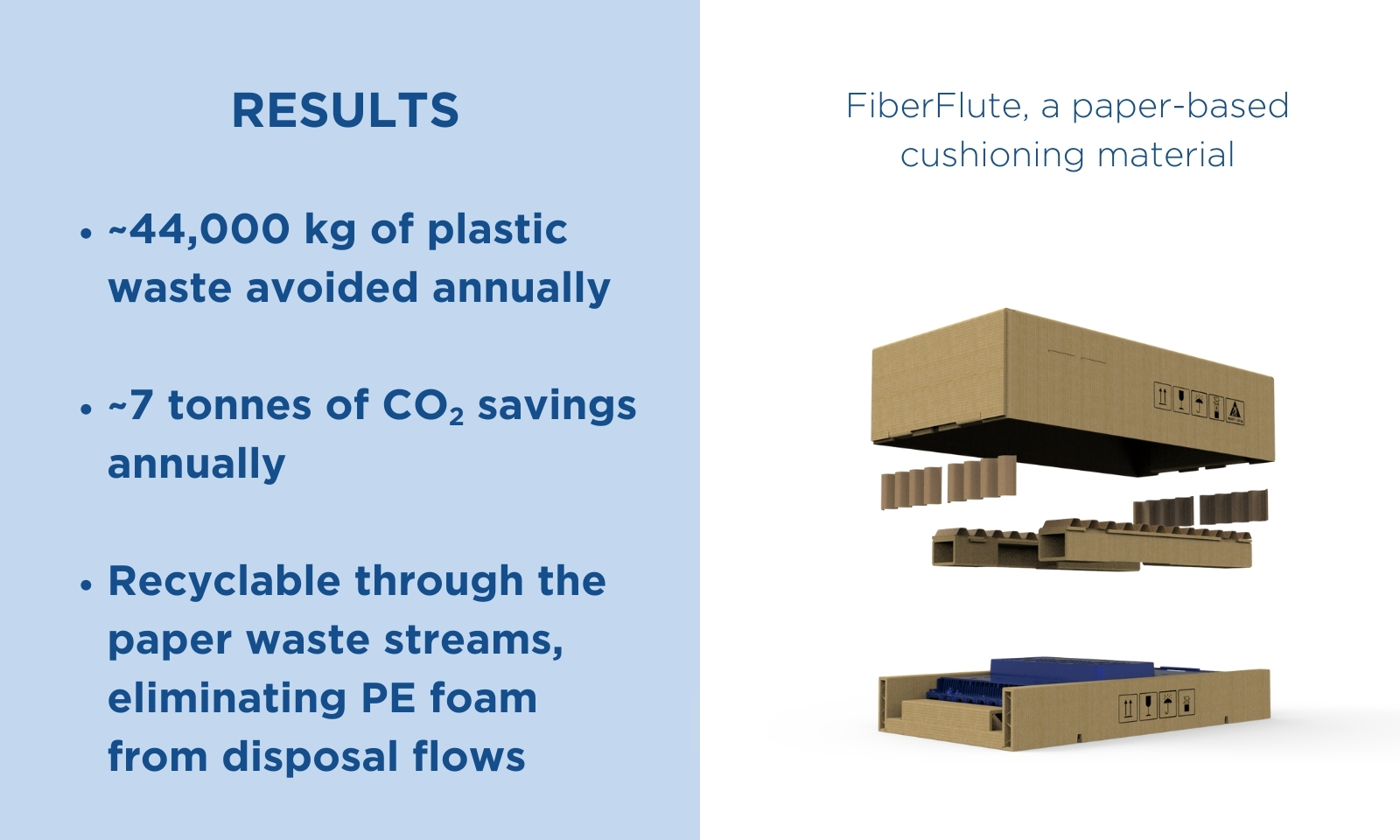

Nefab’s Solution: FiberFlute

Nefab introduced FiberFlute, a paperbased cushioning material engineered to replace plastic foam. Rigorous technical testing demonstrated FiberFlute’s strength and impact resistance, confirming its ability to safeguard the product during transport and handling across the supply chain. The packaging was designed to remain with the product until final installation, ensuring continuous protection, and because FiberFlute is paperbased it can be recycled through established paper waste streams, eliminating the PE foam from disposal flows.

The Results: Improved Sustainability

The new packaging solution resulted in sustainability improvements. Key outcomes included:

- Plastic waste avoided: ~44,000 kg annually by replacing PE foam with FiberFlute.

- Carbon reduction: ~7 tonnes CO₂ saved per year via a lower Packaging Carbon Footprint.

- Protection maintained or improved: Product integrity preserved throughout transport and final installation.

- Recyclability: Packaging can be processed through established paper waste streams, eliminating PE from disposal flows.

- Business impact: Enables the customer to meet sustainability targets while preserving supply chain performance.

Take the Next Step

Switch to high-performance, recyclable fiber packaging today. Our FiberFlute solution helped a global telecom leader avoid 44,000 kg of plastic waste annually while ensuring total product safety from transport to installation. We can help you achieve similar results.

Talk to Our Experts

Learn More About our Solution for the Telecom Industry

Explore more of our smart and sustainable solutions for the Telecom sector and see how we help customers achieve their financial and environmental goals.

Explore the Telecom Solutions Page

Discover comprehensive packaging and logistics solutions designed specifically for the telecom industry.

Related Telecom Customer Cases

Telecom Industry Insights

- How Reverse Logistics and Smart Packaging Power Telecom’s Infrastructure Upgrades: Discover how returnable packaging and digital tracking streamline upgrades, extend equipment life, and support circular supply chains during 5G and 6G rollouts.

- Why Abrasive Protection is Critical for Telecom Hardware in a 5G and 6G World: Learn why protecting sensitive components from scratches and micro-damage is vital for network reliability, and how new fiber-based solutions reduce plastic use while enhancing equipment safety.

- Designing Out Waste in the Telecom Industry Supply Chain: Learn how fiber-based, recyclable, and biodegradable packaging is replacing virgin plastics, letting telecom companies minimize waste and protect equipment even in remote environments.

- Why Telecom Hardware Manufacturers Should Embrace Contract Logistics for Better Inventory Management: Discover how contract logistics enhances inventory visibility, streamlines operations, and elevates delivery reliability to meet the demands of fast-moving telecom supply chains.

- Transforming Telecom Supply Chains: The Power of Innovation and Collaboration.: Explore how industry partnerships, end-to-end supply chain visibility, and sustainable materials are driving the future of telecom supply chain transformation.

Additional Resources