Plastic packaging trays for transport & automated handling

Nefab provides plastic trays designed for sustainability, efficiency, and protection. Our custom tray solutions ensure safe transport, handling, and storage of sensitive components.

Nefab provides plastic trays designed for sustainability, efficiency, and protection. Our custom tray solutions ensure safe transport, handling, and storage of sensitive components.

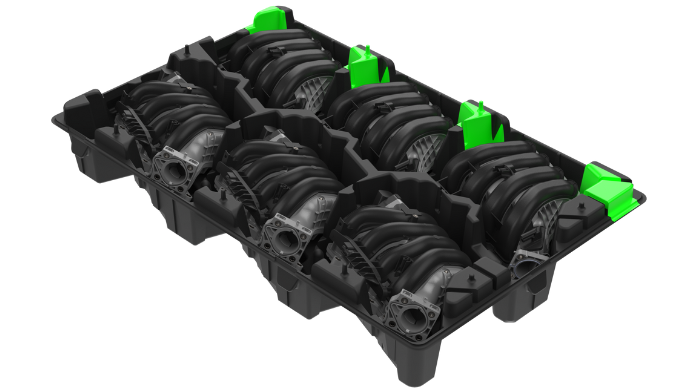

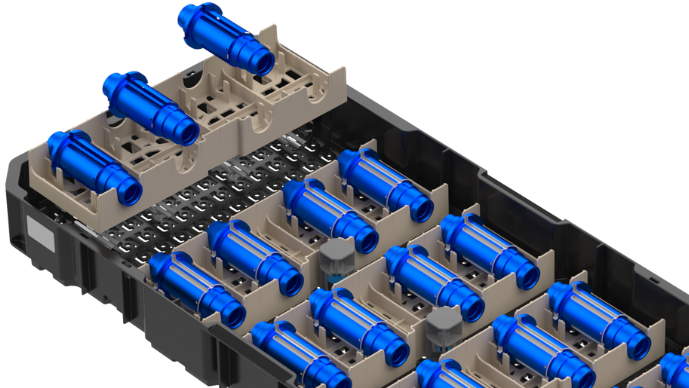

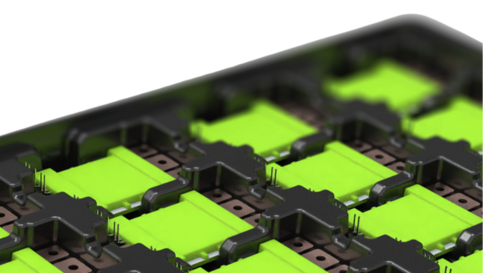

Trays are custom designed to fit complex shapes, minimizing the risk of product damage. Manufactured with high dimensional precision for automated systems.

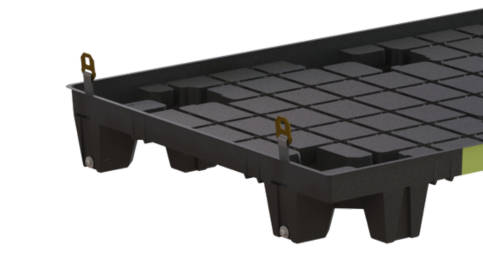

Our recyclable trays, made from up to 100% recycled materials, can be reusable and are designed to save space, cutting environmental impact and costs.

Innovative designs cut manufacturing costs and reduce shipping costs by up to 50% with improved product density and lightweight materials.

Nefab’s plastic trays offer efficient, clean, and customizable packaging solutions for diverse industry needs.

Custom-shaped and available in light to heavy gauges, our plastic trays ensure secure handling and transport of your products. Designed to fit complex shapes, they minimize product movement and reduce the risk of damage.

Plastic trays can be further customized with a variety of protective elements. Options include ESD protection, anti-scratch surfaces to maintain the integrity of sensitive components, vibration dampening, as well as chemical and dust resistance, ensuring that your products are safeguarded against environmental hazards during transport.

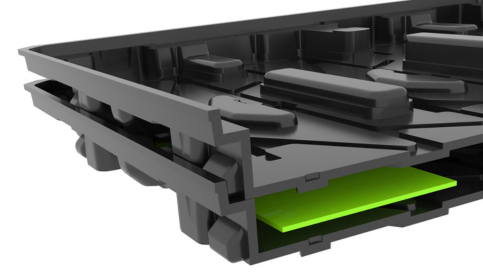

Nefab utilizes advanced manufacturing methods, including injection molding, thermoforming, and urethane casting. We work with resins such as HDPE, PS, PET, PC-ABS, ABS, TPU, and PP to create the most efficient packaging solution in line with customer needs. Made with up to 100% recycled content and fully recyclable materials, Nefab's trays reduce waste and environmental impact.

In-process trays are designed to support the in-plant manufacturing process.

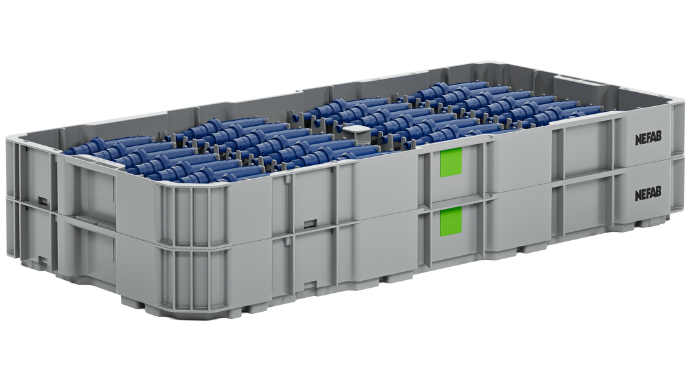

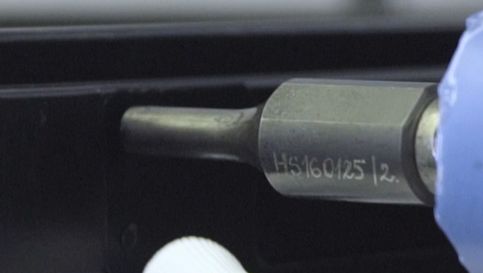

Automation trays offer a high level of tolerance with key features for automation systems.

Transport trays are optimized to protect components during transport and to enable efficient logistics.

Nefab's plastic trays are designed to meet the needs of industries such as pharmaceuticals, healthcare, medical, automotive, and lithium-ion batteries. Engineered to securely hold components like drive trains, gearboxes, sensors, printed circuit boards (PCBs), and other essential parts, these trays ensure safe, damage-free transportation while supporting efficient automated handling.

Nefab designs and manufactures precision automation trays tailored for robotic and automated assembly systems. By leveraging advanced manufacturing techniques such as injection molding and high-precision thermoforming, we can create trays with the exacting dimensional accuracy required for modern automation.

Each tray is custom engineered to securely hold parts in precise positions. Key features that enable seamless compatibility with lasers, sensors, and robotic grippers include custom inserts, vision targets, and integrated fork pockets. Made from high-quality materials, Nefab's automation trays are durable and maintain their integrity even with repeated use.

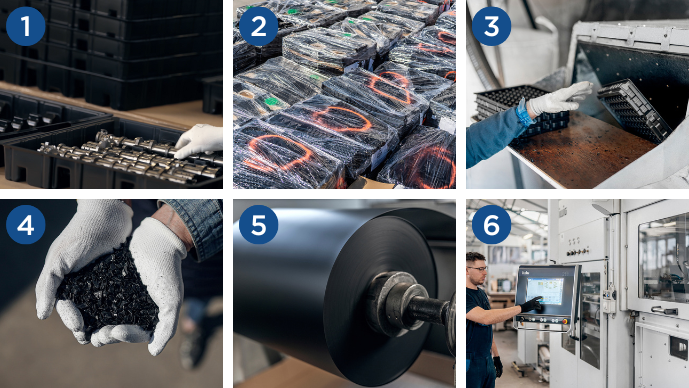

The recycling of thermoformed trays

1 - Packaging in use; 2 - Collection at end of life; 3 - Grinding; 4 - Grinded offcuts; 5 - Recycled material after re-extrusion; 6 - Production of new packaging

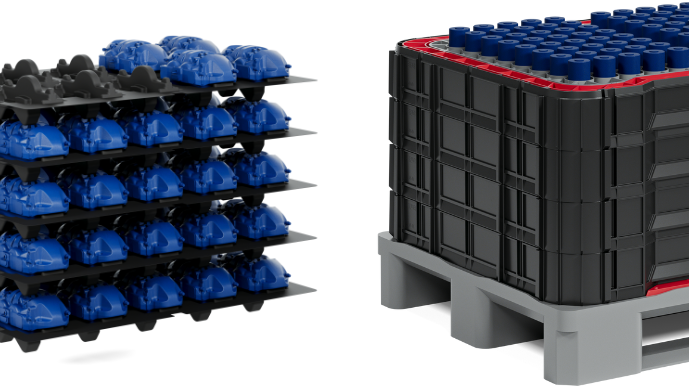

Nefab’s plastic trays are designed with circular economy in mind. Made with up to 100% recycled materials, these trays are not only fully recyclable but can also be reusable, reducing waste and minimizing landfill contributions. Nestable designs save space, lowering both environmental impact and supply chain costs. By replacing one-way packaging with reusable plastic solutions, Nefab has helped customers achieve significant CO2 reductions, ranging from 25% to 81%.

Nefab designs trays for optimized efficiency and reduced costs. Our trays integrate seamlessly into automated manufacturing, reducing touches, improving production flow, minimizing damage, and saving floor space. With enhanced product density and lightweight materials, they can reduce shipping costs by up to 50%. Their innovative design also supports high-volume production, lowering manufacturing costs per unit without compromising quality.

Nefab's thermoformed trays range from light-gauge to heavy-gauge

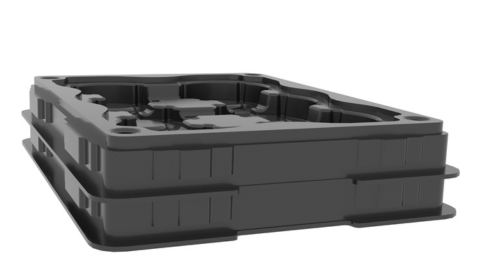

Thermoformed trays are an ideal packaging solution for businesses seeking cost-effective, durable, and versatile options. Perfect for low to medium production volumes, thermoforming offers lower tooling costs and shorter lead times compared to injection molding, enabling faster time-to-market. This method also supports the creation of representative prototypes for reliable testing and assessment. Nefab can thermoform trays with different thickness, from light-gauge to heavy-gauge. Additionally, thermoformed trays can be designed for reusability and engineered to support automated handling systems.

Injection molded trays are ideal for businesses needing precise, high-volume packaging. They offer cost efficiency for medium to large production runs and deliver exceptional accuracy, ideal for automated handling systems. The process allows for complex shapes to protect specific components and uses a variety of resins with advanced material properties for specialized needs. Designed for reusability, these trays fit seamlessly into returnable logistics.

Nefab has the capabilities to combine thermoformed and injection-molded parts to create efficient complete packaging solutions. By integrating trays with custom inserts, we provide a cost-effective way to optimize packaging while ensuring maximum product protection. This approach also supports long-term reuse of trays, making them adaptable for various applications and programs.

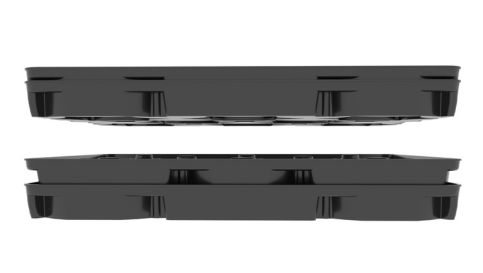

Trays can be designed to nest efficiently when empty, significantly reducing storage space and return freight costs in reusable systems. This space-saving design leads to lower logistical costs and a reduced carbon footprint.

Stackable and nestable by 180º rotation. Reversible stack/nest plastic trays are designed to stack securely when full and nest compactly when empty. A simple 180º spin saves space and maximizes storage

Undercut thermoformed trays feature inward or outward curves to grip products firmly, ensuring protection and preventing movement during transport. Undercuts require more complex mold making and thermoforming capabilities. The trays are stackable in the same position but with alternate rotation.

Dust-proof trays stack tight to protect products from contamination through dust particles. They can be molded from anti-static materials. These trays can be made reversible with stack/nest capabilities.

ESD trays protect electronic components from electrostatic discharge during handling, storage, and transport. Made from conductive or dissipative materials, they prevent static buildup and protect delicate parts. They offer static protection, organized storage, and reduced damage risk, making them essential in electronics manufacturing.

For our US-based customers, we offer our standard plastic solutions in a B2B web shop. Effortless ordering, sustainable packaging solutions, and fast delivery – all in one place. Our product selection features standard solutions, including thermoformed pallets, plastic inline trays, TPU buttons, brackets, and rack accessories.

Hot-stamping, screen printing, or labels are available for identification and branding.

Ultrasonic welding can be applied to add card holders and similar add-ons.

Multiple sheet and stripe color options are available for visual identification.

Trays can be fitted with barcodes, tags, and trackers to allow asset tracking.

Nefab saves environmental and financial resources by optimizing supply chains. We do so by innovating together with our customers to create smarter packaging and logistics solutions while always respecting people and ethical standards.

We provide complete packaging and logistics solutions that reduce total cost and environmental impact throughout the supply chain.

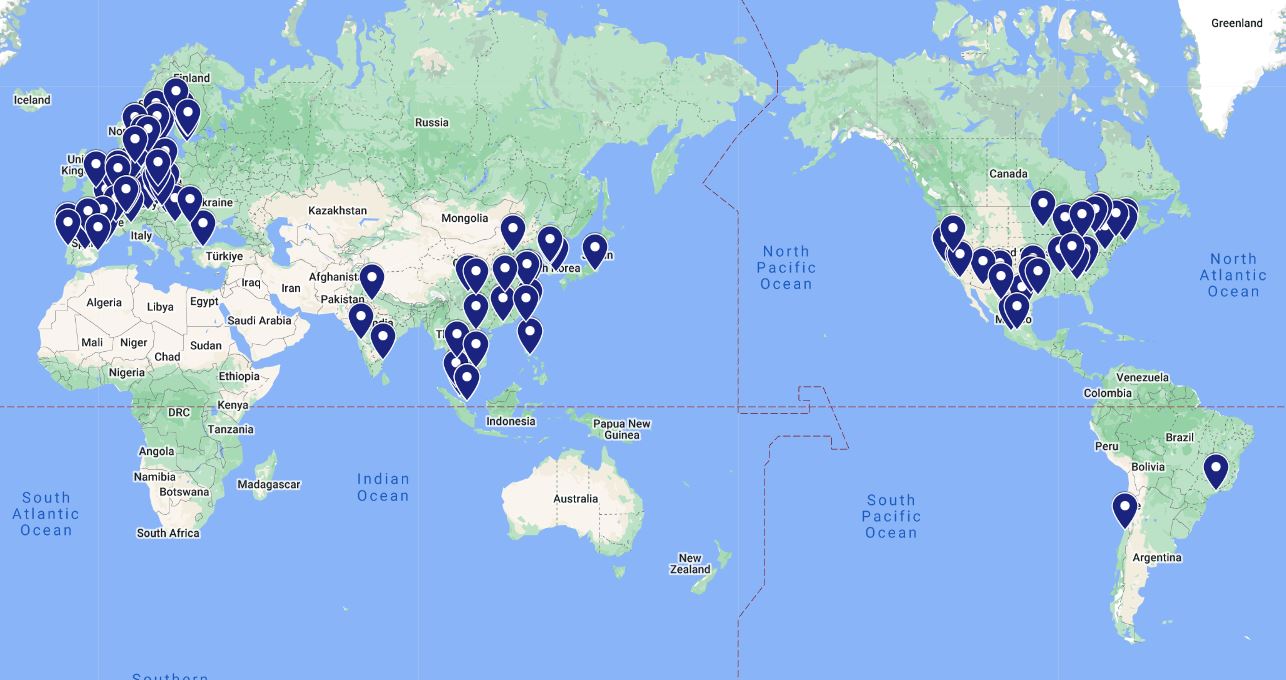

With over 250 engineers in 30 locations globally, we collaborate closely with customers to design, prototype, test, and deliver tailored packaging solutions.

Nefab's solutions reduce carbon footprints by 31%, on average, reflecting our commitment to sustainability within our operations and offerings.

With 75 years of experience and a presence in over 38 countries, we deliver global solutions with local support.

Are you looking for a plastic tray? Reach out to us today! Our team of experts in more than 39 countries is ready to collaborate, innovate, and deliver solutions tailored to your unique challenges. Contact your local sales representative for more information about Nefab trays and discover how they can enhance your logistics and sustainability efforts.

Custom pallets for specialized transport needs

Reusable plastic shipping and storage containers, totes, and bins

Custom inserts and inner fittings for product securement