The Challenge: Cost, Efficiency & Sustainability for Specialized Point-of-Sales Hardware

A leading software and technology company providing electronic products and professional services worldwide faced critical challenges in their distribution process. Their products, shipped globally via sea freight, required specialized packaging for secure transportation. However, their in-house pallet designs were inefficient, accommodating only 18 units per container and making the packages non-stackable. The materials used, including plywood, pinewood, and plastic cushion doughnuts, faced extended lead times, high minimum order quantities, and contributed to increased costs during a period when container prices surged by 400%.

Further, the pandemic exacerbated these hurdles, accelerating the need for effective cost-reduction measures while supporting sustainability goals.

Nefab's Solution: Lightweight Foam Pallet Solution

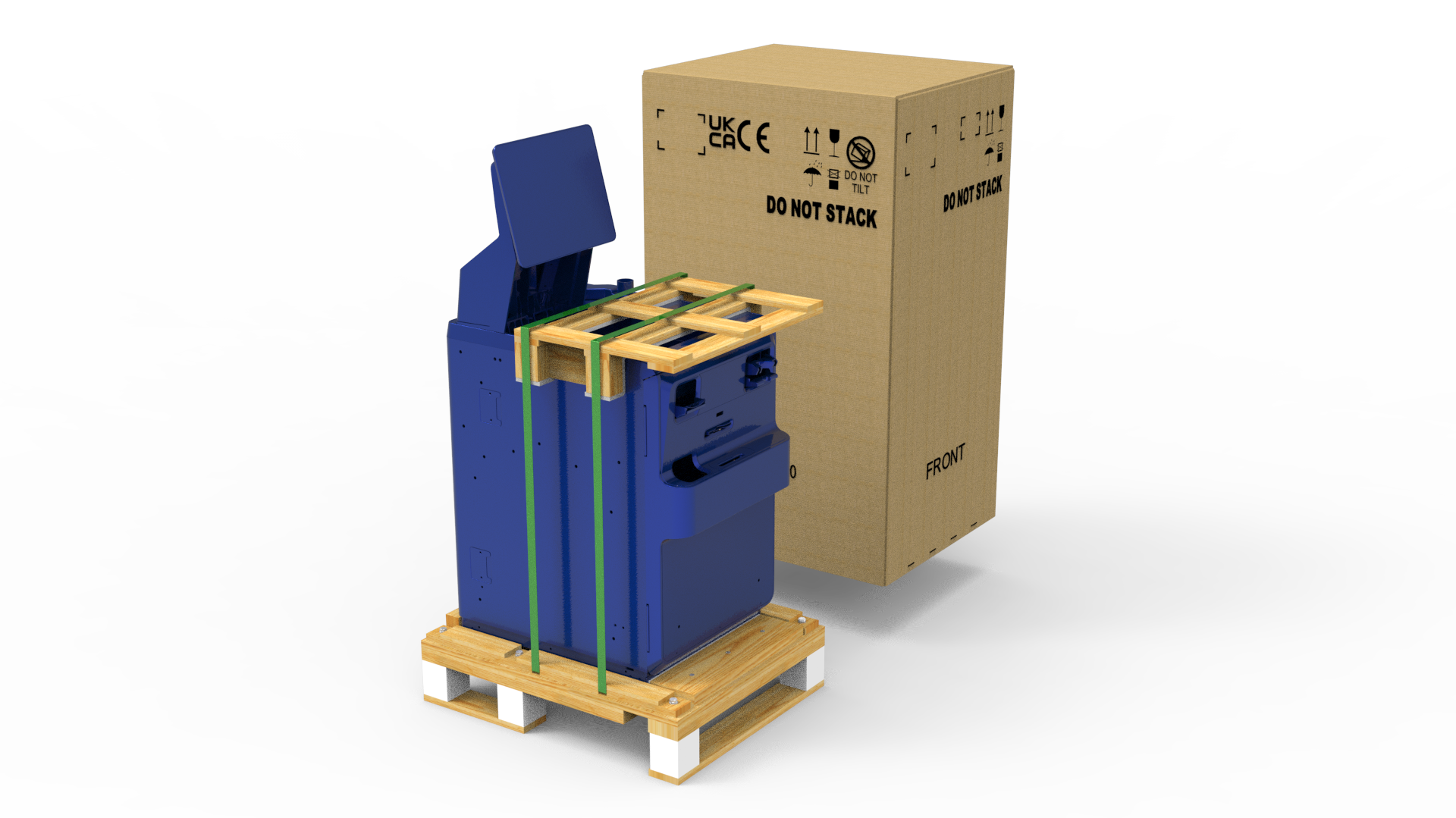

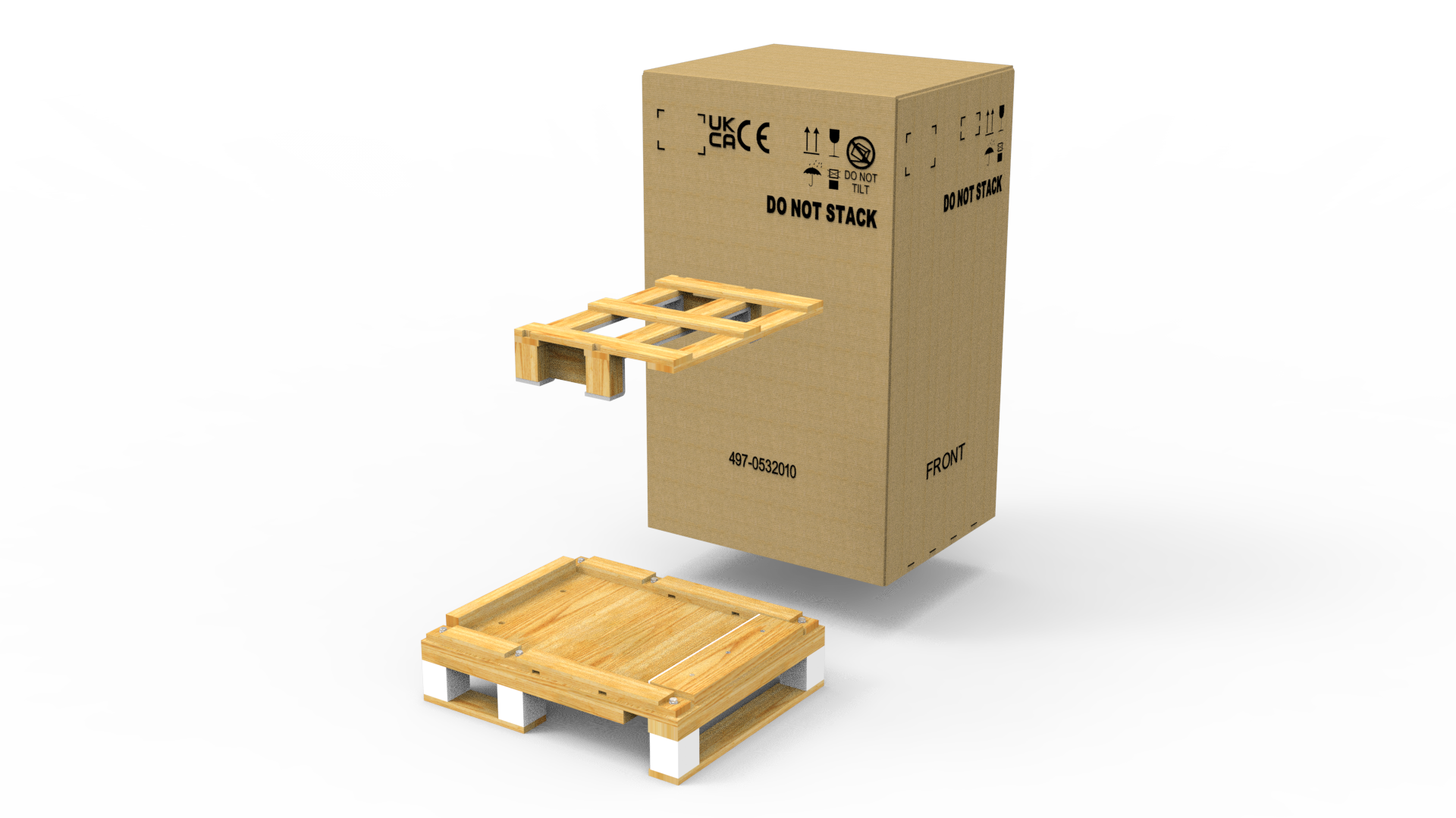

To tackle these issues, the packaging team proposed an innovative and lightweight foam pallet solution. The solution utilized two advanced PE foam pallet variants. The redesign included the following key improvements:

- Enhanced Container Capacity: Increased storage from 18 units per container to 45 units for one variant and 53 units for the other.

- Improved Securing Mechanisms: Introduced plywood corners, foam cushions, base pallet straps, and top fitments to protect units during transit.

- Lighter Weight Design: Reduced the overall design weight, enabling ease of handling and cost-effective shipping.

- Optimized Production Process: Enabled faster processing on conveyor systems by accommodating more pallets simultaneously, boosting daily production capacity from 100 units to 150 units per day.

The solution underwent rigorous testing and validation, meeting all the requirements for safety, durability, and functionality, which were critical to large-scale implementation.