The Challenge: Balancing GPU Protection, Sustainability, and Cost

A leading multinational technology company, known for its advanced technology products, faced significant challenges when launching a new GPU. Their existing packaging solution, composed of foam and corrugated components, was proving inadequate. Damage during handling and transit led to increased costs and inefficiencies.

Additionally, the company wanted to enhance sustainability. They aimed to explore a closed-loop, returnable packaging system that could reduce their environmental footprint while maintaining product safety. Given the complexity and sensitivity of their new GPU, these challenges required an innovative solution that balanced performance, sustainability, and cost-efficiency.

Nefab's Solution: HDPE Thermoformed Reflex Cushion for GPUs

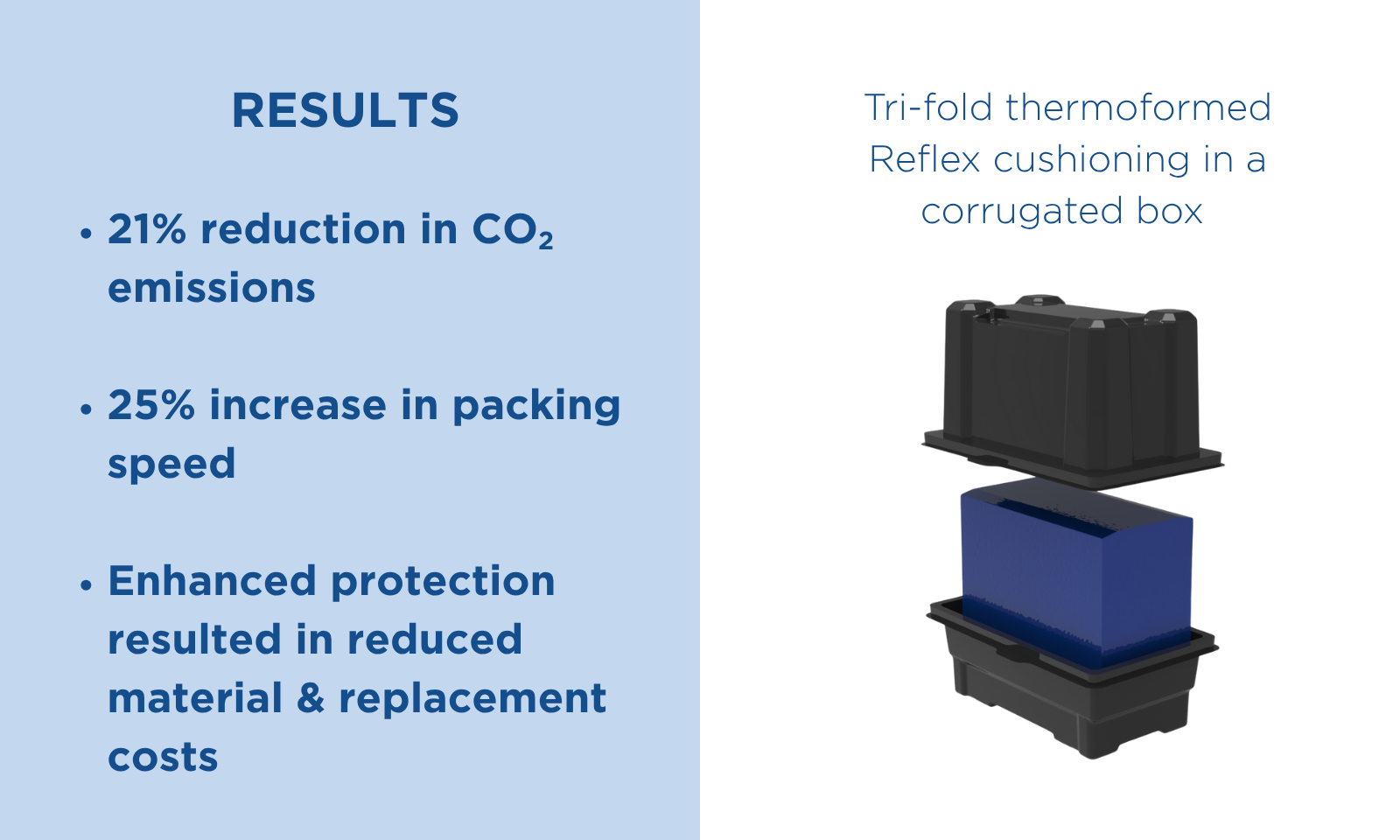

A customized solution was developed to address these issues—a trifold HDPE thermoformed Reflex cushion. This innovative design wraps securely around the product, providing optimal protection during transit. The cushion is made of 100% recycled HDPE that is fully recyclable.

For added protection, an anti-static LDPE bag was incorporated into the setup, ensuring the sensitive electronic components remained undamaged. The new solution also optimized handling thanks to its ergonomic design and reduced dimensions, enabling better packing efficiency and lower transportation costs.

To further streamline the process, the packaging system was implemented as part of a closed-loop flow. After use, components were returned, inspected, and reintroduced into circulation.

The Results: Sustainability and Efficiency Benefits with Cost Savings and Damage Reduction

The introduction of the new solution yielded remarkable benefits, including:

- Sustainability Gains: CO2 emissions were reduced by 21%, aligning with the company’s environmental goals.

- Improved Efficiency: Packing speed increased by 25%, leading to operational savings.

- Cost Savings: The closed-loop system meant parts could complete up to four cycles before being retired, significantly lowering material costs.

- Damage Reduction: Product damages during transit and handling were minimized, reducing replacement expenses and building customer confidence.

This innovative solution provided a significant step forward in the company’s sustainability efforts while also meeting their operational and financial goals. With its successful implementation, the partnership set the stage for future collaborations as the company continues to innovate and scale globally.

Ready to Transform Your Packaging and Supply Chain

Your advanced components, like GPUs, demand packaging that offers superior protection without compromising sustainability or efficiency. Our innovative HDPE thermoformed Reflex cushion, made from 100% recycled materials, provides a closed-loop solution that reduces damage, cuts costs, and minimizes your environmental footprint. This solution increased packing speed by 25% and lowered CO2 emissions by 21% for a leading technology partner.

Talk to Our Experts

Learn More About our Solution for the Datacom Industry

Discover our full range of innovative packaging for the datacom and cloud industry..

Explore the Datacom Solutions Page

Discover packaging and logistics solutions designed specifically for the Datacom industry.

Related Datacom Customer Cases

- Optimized Packaging for Motherboards:Learn how we improved protection and density for sensitive motherboard shipments.

- Innovative Packaging for POS Hardware: Discover how Nefab’s lightweight foam pallets helped a leading tech firm save $2.5 million annually and slash CO2 emissions by 572 metric tons. By optimizing container capacity and logistics for POS hardware, we helped them achieve a more sustainable, cost-effective supply chain

Datacom Industry Insights

Additional Resources